Biological composite enzyme of pretreatment refining process for cotton fabric dyeing and finishing, and pretreatment refining process thereof

A biocomposite enzyme and cotton fabric technology, applied in the direction of enzyme/microbial biochemical treatment, fiber treatment, biochemical fiber treatment, etc., can solve the problems of reducing application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

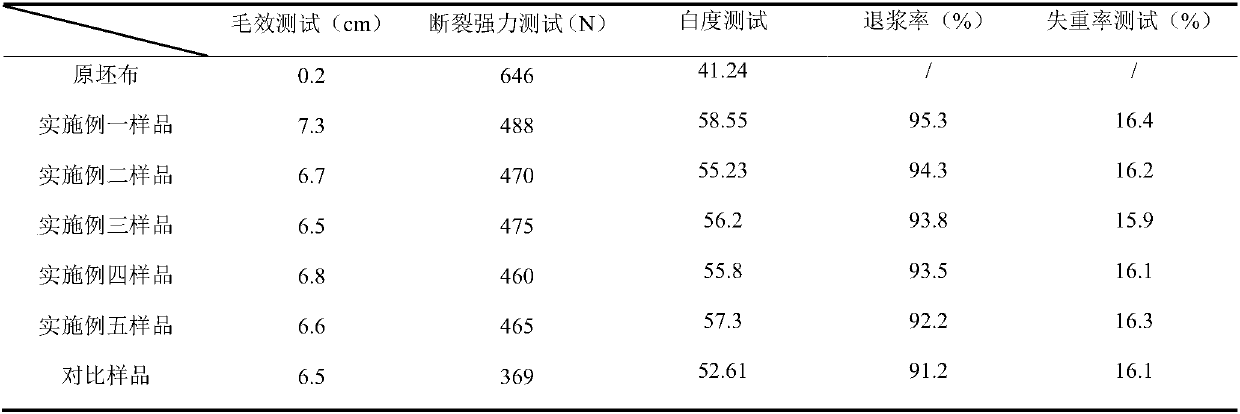

Examples

Embodiment 1

[0021] A biological composite enzyme used in the pretreatment and scouring process of cotton fabric dyeing and finishing, which is composed of a-amylase, pectinase and cellulase, and its weight content is 25% of a-amylase and 62.5% of pectinase % and cellulase 12.5%.

[0022] A kind of biological compound enzyme used in the pretreatment scouring process of cotton fabric dyeing and finishing is used in the pretreatment scouring process of cotton fabric dyeing and finishing, specifically as follows:

[0023] Step 1. Control the pH of the scouring solution to 7, and control the scouring temperature in a water bath to 65°C.

[0024] Step 2, add the above biological complex enzyme, the dosage is 4g / L; add citric acid 0.05g / L;

[0025] Step 3, add non-ionic surfactant JFC, the dosage is 1g / L;

[0026] Step 4, scouring the cotton fabric under the condition that the bath ratio is 1:20, the scouring time is 70min,

[0027] Step 5: After the scouring is completed, the cotton fabric i...

Embodiment 2

[0029] A biological compound enzyme used in the pretreatment and scouring process of cotton fabric dyeing and finishing, which is composed of a-amylase, pectinase and cellulase, and its weight content is 23.8% of a-amylase and 71.4% of pectinase % and cellulase 4.8%.

[0030] A kind of biological compound enzyme used in the pretreatment scouring process of cotton fabric dyeing and finishing is used in the pretreatment scouring process of cotton fabric dyeing and finishing, specifically as follows:

[0031] Step 1. Control the pH of the scouring solution to 7, and control the scouring temperature in a water bath to 50°C.

[0032] Step 2, add the above biological complex enzyme, the dosage is 2.5g / L; add citric acid 0.02g / L;

[0033] Step 3, add non-ionic surfactant Span-80, the dosage is 0.5g / L;

[0034] Step 4, the cotton fabric is scoured under the condition that the liquor ratio is 1:25, and the scouring time is 50min;

[0035] Step 5: After the scouring is completed, the...

Embodiment 3

[0037] A biological compound enzyme used in the pretreatment and scouring process of cotton fabric dyeing and finishing, which is composed of a-amylase, pectinase and cellulase, and its weight content is 27.3% of a-amylase and 54.5% of pectinase % and cellulase 18.2%.

[0038] A kind of biological compound enzyme used in the pretreatment scouring process of cotton fabric dyeing and finishing is used in the pretreatment scouring process of cotton fabric dyeing and finishing, specifically as follows:

[0039] Step 1. Control the pH of the scouring solution to 8, and control the scouring temperature in a water bath to 80°C.

[0040] Step 2, add the above biological complex enzyme, the dosage is 5.5g / L; add sorbitol 0.1g / L;

[0041] Step 3, add non-ionic surfactant Tween-80, the dosage is 2.0g / L;

[0042] Step 4, scouring the cotton fabric under the condition that the liquor ratio is 1:35, and the scouring time is 90min;

[0043] Step 5: After the scouring is completed, the cot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com