Patents

Literature

54results about How to "Remove help" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for coagulating coal-bed gas produced water

InactiveCN102060363AEasy to handleResource optimizationWater/sewage treatment by flocculation/precipitationChemical compoundSuspended matter

The invention relates to a method for coagulating coal-bed gas produced water, which is realized in a way that: coal-bed gas produced water is coagulated by combining a chemical compounded from an inorganic coagulant and an organic flocculant with a coagulation assistant, or combining an inorganic coagulant, an organic flocculant and a coagulation assistant; a pretreatment pool is arranged at the outlet of the coal-bed gas produced water, a coagulation assistant dissolving box is arranged at the water inlet of the pretreatment pool, and the amount of the coagulation assistant is controlled by using a measuring pump or flowmeter; and the coal-bed gas produced water is firstly conditioned by the coagulation assistant, and then treated by the chemical compounded from the inorganic coagulant and the organic flocculant, or treated by combining the inorganic coagulant and organic flocculant. The amounts of the compounded or combined inorganic coagulant and organic flocculant are controlled by using the measuring pump or flowmeter, thereby effectively removing suspended matters in the coal-bed gas produced water, being beneficial to removing oil, multiple soluble ions, other organic substances and the like, reducing the consumption of chemicals and relieving the treatment load of the subsequent technique, so that the treated produced water can be discharged under the standard or can be conveniently recycled.

Owner:CHINA UNIV OF MINING & TECH +2

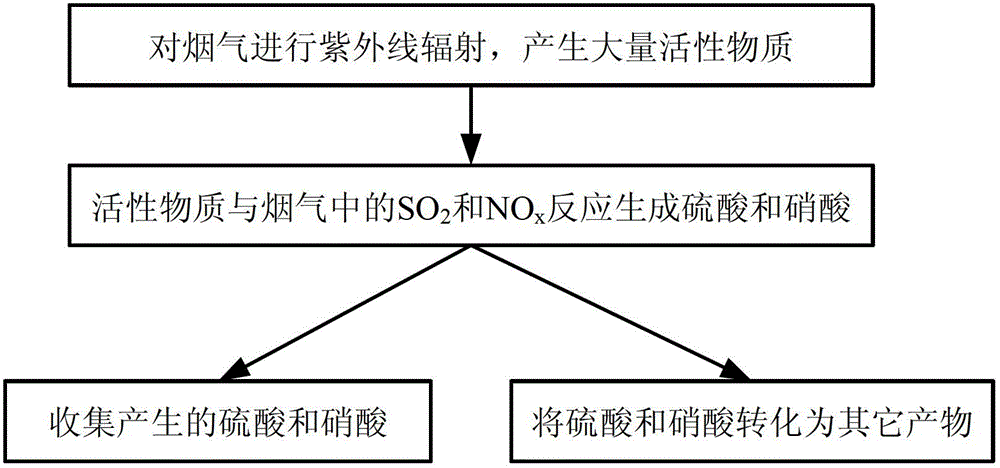

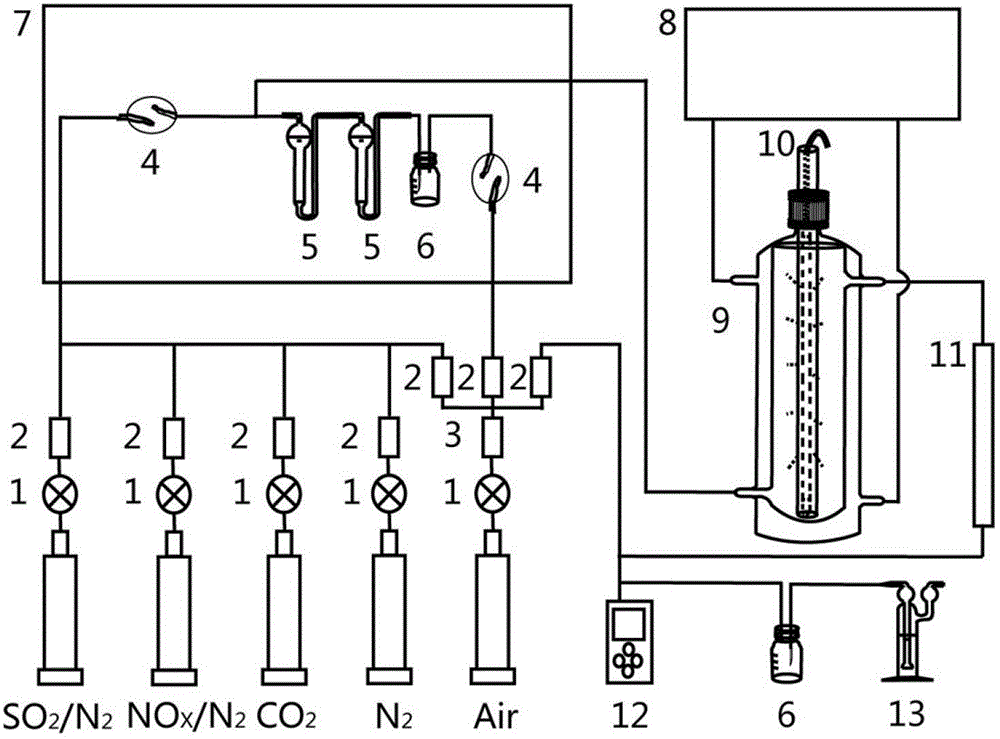

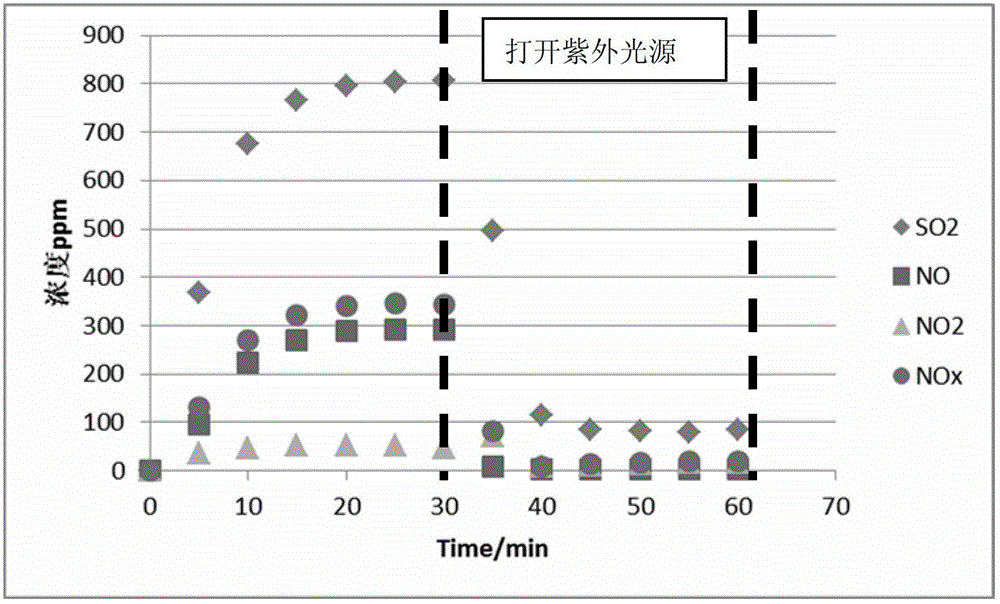

Method for simultaneously desulfurizing and denitrating flue gas

ActiveCN102908883APromote oxidationTo achieve the purpose of simultaneous desulfurization and denitrificationDispersed particle separationAir quality improvementAmmonium nitrateAmmonium sulfate

The invention provides a method for simultaneously desulfurizing and denitrating flue gas. The method comprises the step that: a large number of active materials produced by the flue gas under ultraviolet radiation are reacted with SO2 and NOx in the flue gas so as to produce stable sulfuric acid and nitric acid which are important industrial products. The two products can be collected by an acid mist removing device, or ammonia can be introduced into the two products to produce ammonium sulfate and ammonium nitrate which are important chemical fertilizers, or calcium carbonate is sprayed into the two products to produce calcium sulfate and calcium nitrate; and then, SO2 and NOx in the flue gas are removed from the flue gas to be converted into the products with the industrial or agricultural value. The method for simultaneously desulfurizing and denitrating the flue gas is suitable for desulfurizing and denitrating the flue gas of large newly-built boilers, or reforming and applying built burning equipment, and can realize the effect of simultaneously removing SO2 and NOx.

Owner:PEKING UNIV

Boiler decoking agent

The invention discloses a liquid decoking agent for coal fired boiler, falling into the technical field of coal fired boiler clean combustion and environmental protection control. The liquid decoking agent comprises a decoking agent 0.5-5 wt%, an oxidant 5-25 wt%, a combustion-supporting catalyst 1-10 wt%, an anticorrosion agent 5-30 wt% and water in balance. The decoking agent can promote combustion and falling of coke-layer matter; the oxidant nitrate can release oxygen gas under high temperature, to promote combustion of different positions of dust and carbon; the combustion-supporting catalyst, potassium permanganate and manganese oxide, can act as oxygen atom reaction carrier under high temperature and catalyze combustion of coal powder; and the anticorrosion agent, modified nano-alumina or nano-magnesia, can convert low-melting-point compound in coke layer into loose high-melting-point compound, which facilitates removal of coked layer and prevention of high-temperature corrosion, and after long-term use, the nano-alumina or nano-magnesia will be attached to a heated surface to form a micro-scale anticorrosion layer.

Owner:SNTO TECH GRP

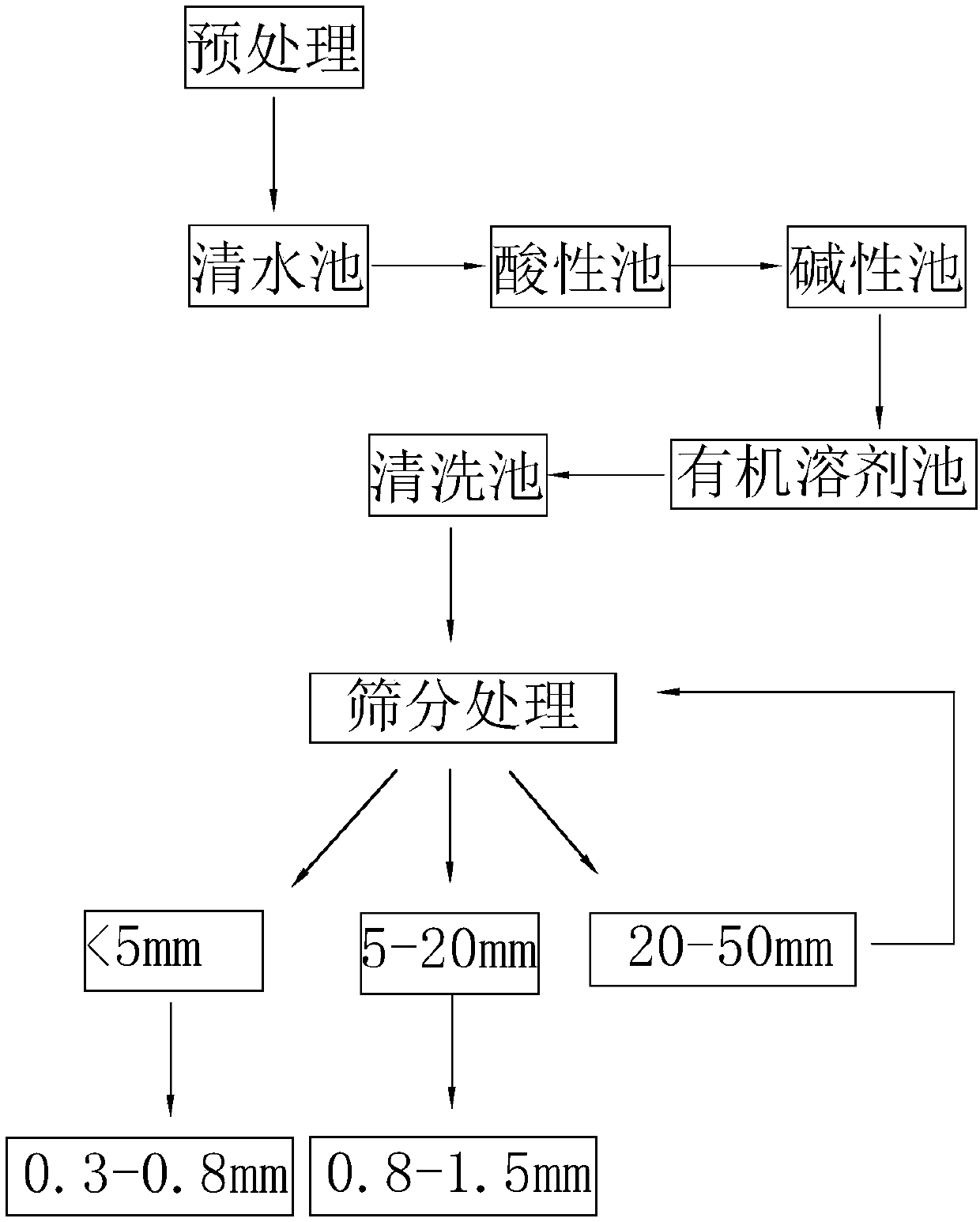

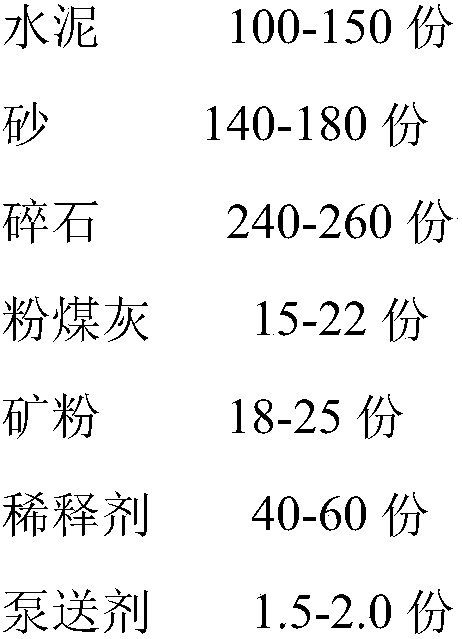

Concrete regeneration process and concrete formula

The invention relates to a concrete regeneration process and a concrete formula. The process comprises the following steps: step 1, pretreatment; step 2, impurity filtration; step 3, impurity adsorption; step 4, screening treatment; step 5, crushing treatment; and step 6, drying and collection. Various raw materials adopted in the scheme meet an environmentally-friendly concept, and in the raw materials, materials such as mineral powder, fly ash and mineral admixture are waste materials, and the process belongs to waste utilization and reasonable application of resources; recycled aggregate has the characteristics of high porosity, large water absorption rate and the like, and therefore the recycled concrete is a porous material; and human walking ways do not have high requirements on load-bearing capacity, and therefore the recycled concrete can be used through casting molding.

Owner:国泷集团有限公司

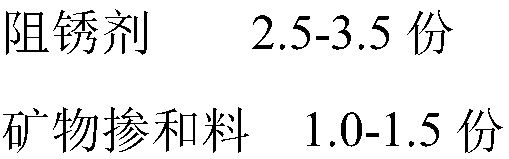

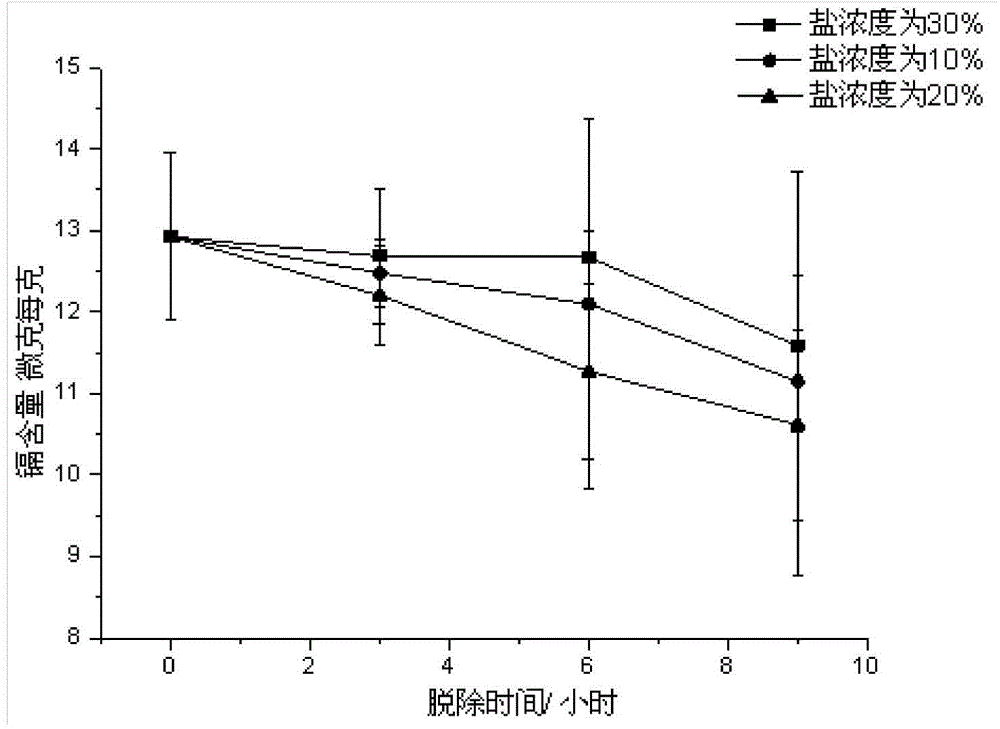

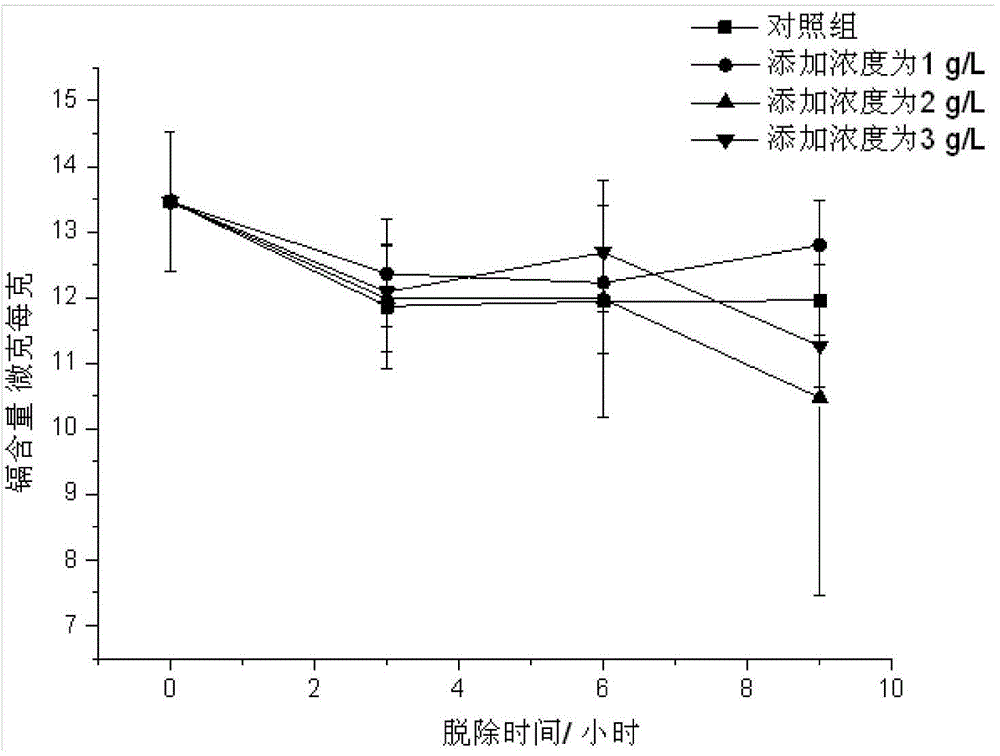

Removing agent for rapidly removing cadmium in shellfishes and preparation method of removing agent

The invention discloses a removing agent for rapidly removing cadmium in shellfishes and a preparation method of the removing agent. The preparation method comprises the steps of uniformly mixing weighed vitamin C, EDTANa2, calcium chloride, chitosan and table salt, and adding the acquired mixture into water, so as to obtain the removing agent. According to the removing agent provided by the invention, the content of cadmium in the shellfishes can be effectively reduced, the removing agent is beneficial for removing cadmium in the shellfishes in shellfish production and processing enterprises and is also suitable for removing cadmium in the shellfishes bought by families, the production value of the shellfishes is increased, and meanwhile, the edible safety of shellfishes is improved. The removing agent has the advantages that the operation is easy, the removal cycle is short, and the removal rate is high.

Owner:JIMEI UNIV

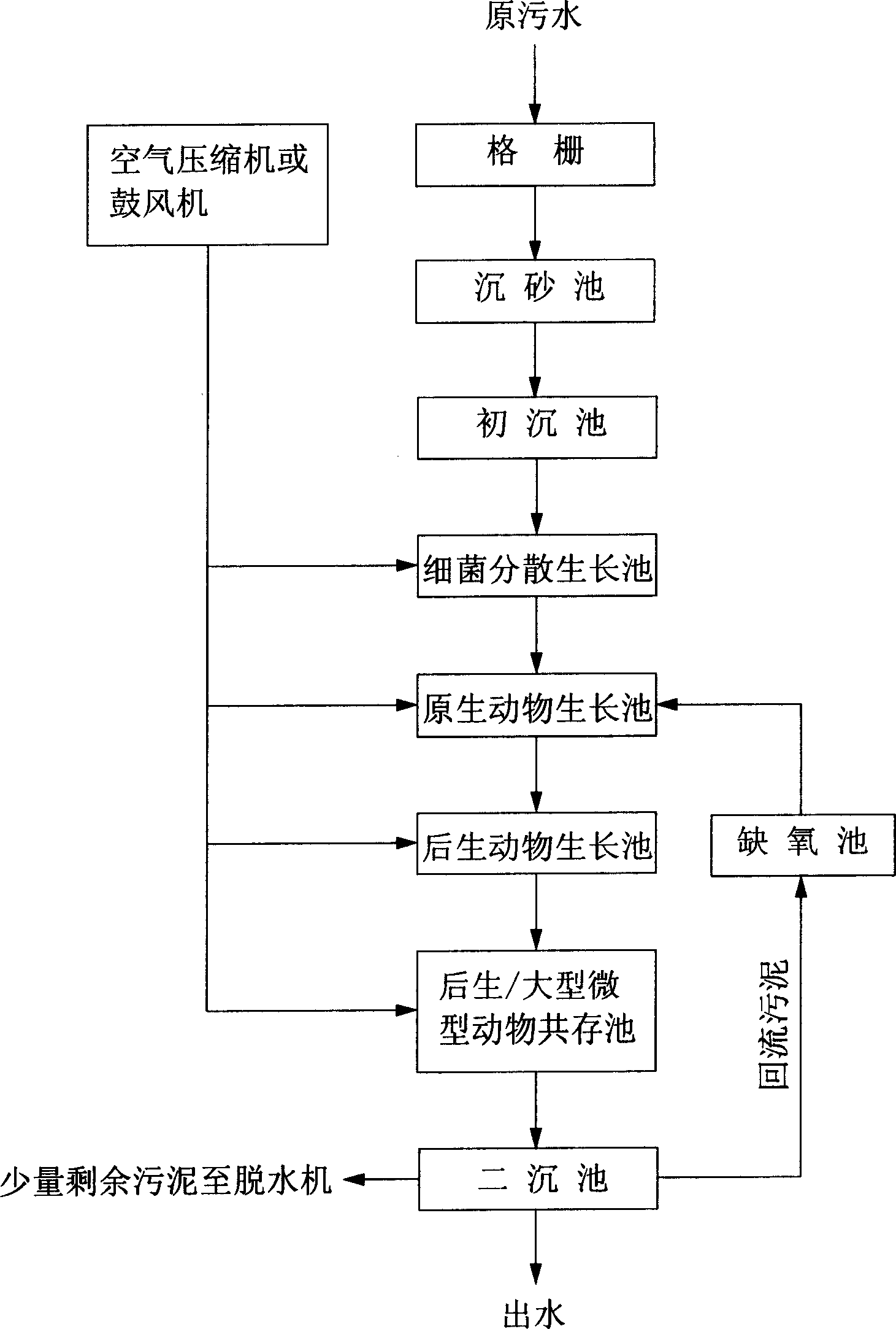

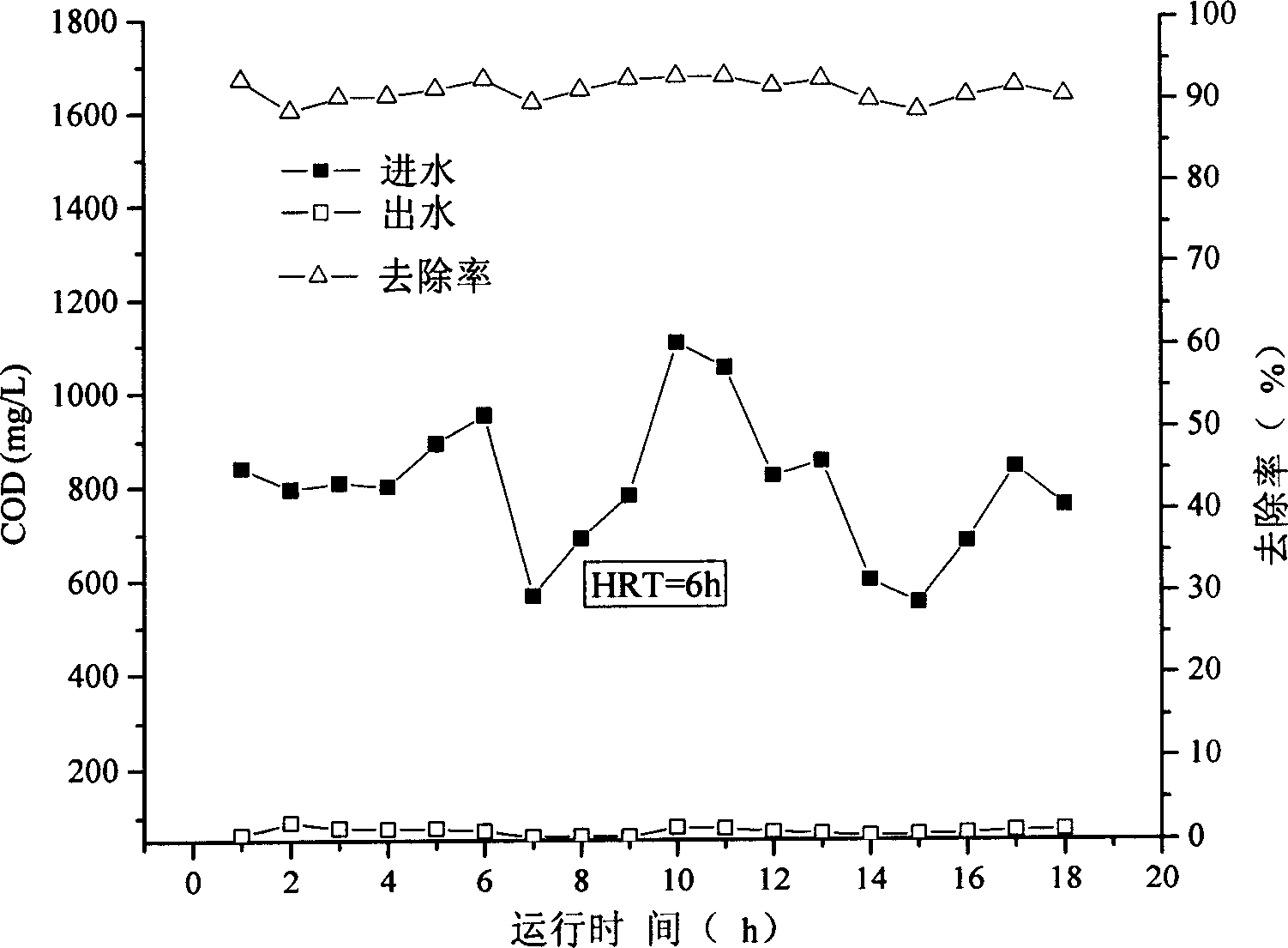

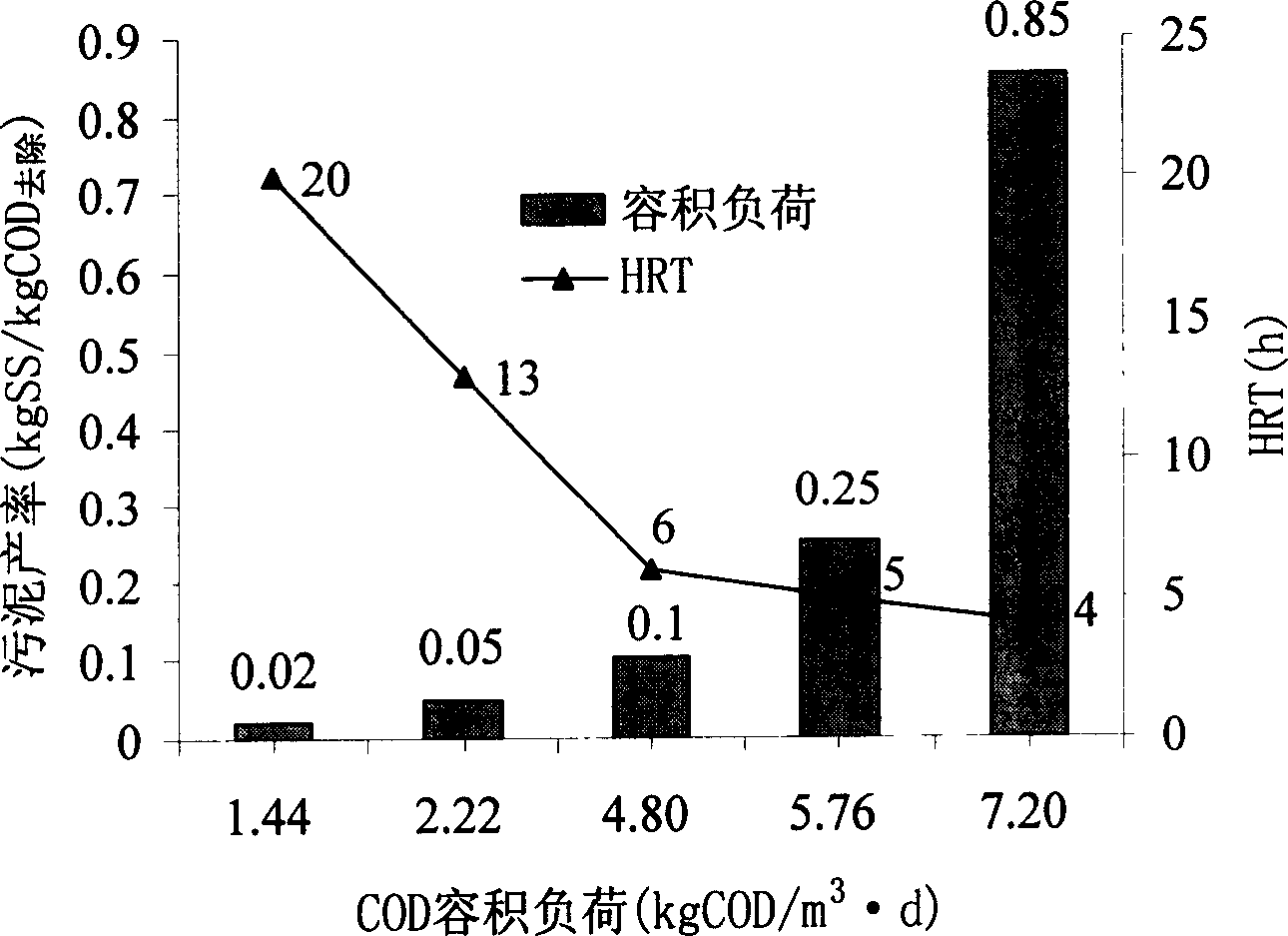

Process for high performance treatment of organic sewage and reduction of excess sludge output

InactiveCN1884127AReduce outputImprove purification effectTreatment with aerobic and anaerobic processesBiotechnologyProtozoa

The invention discloses a disposing method of organic waste water and residual mud reducing method in the dirty water disposing domain through biological technology, which is characterized by the following: the effluent disposal technology contains first-grade physiochemical disposal, aerobic segment two-grade physiochemical disposal and mud separation of two sedimentation pools; the nourishing grade of aerobic segment is divided into the following four parts from junior to senior according to food chain: bacteria dispersing growing pool, protozoa growing pool, meteorology growing pool and large-scale micro-animal growing pool; the bacteria decompose organics and the protozoa, meteorology and large-scale micro-animal reduce mud quantity to assist to decompose organics. The invention can be applied in the urban effluent disposal and industrial effluent disposal, which reduces mud quantity.

Owner:B TOHIN MACHINE JIANGSU

Air cleaner

ActiveCN105423416ANo toxic residueReduce lossMechanical apparatusLighting and heating apparatusParticulatesElectric discharge

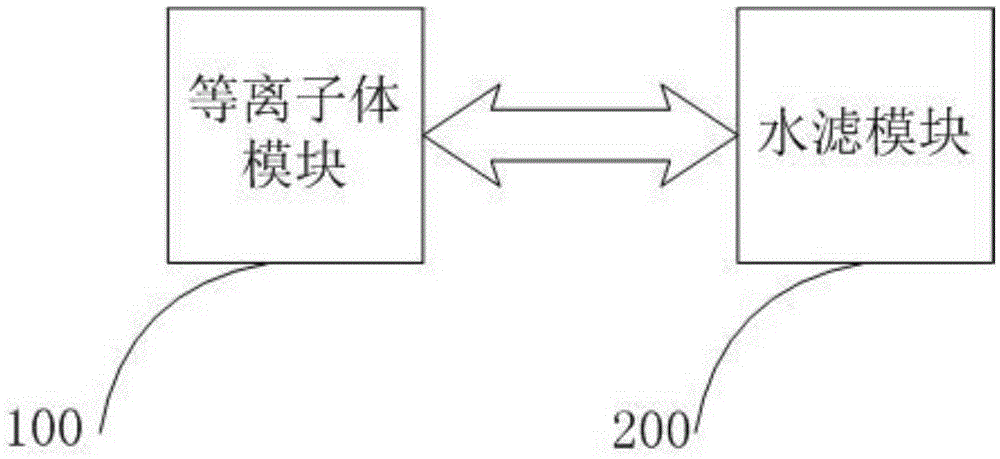

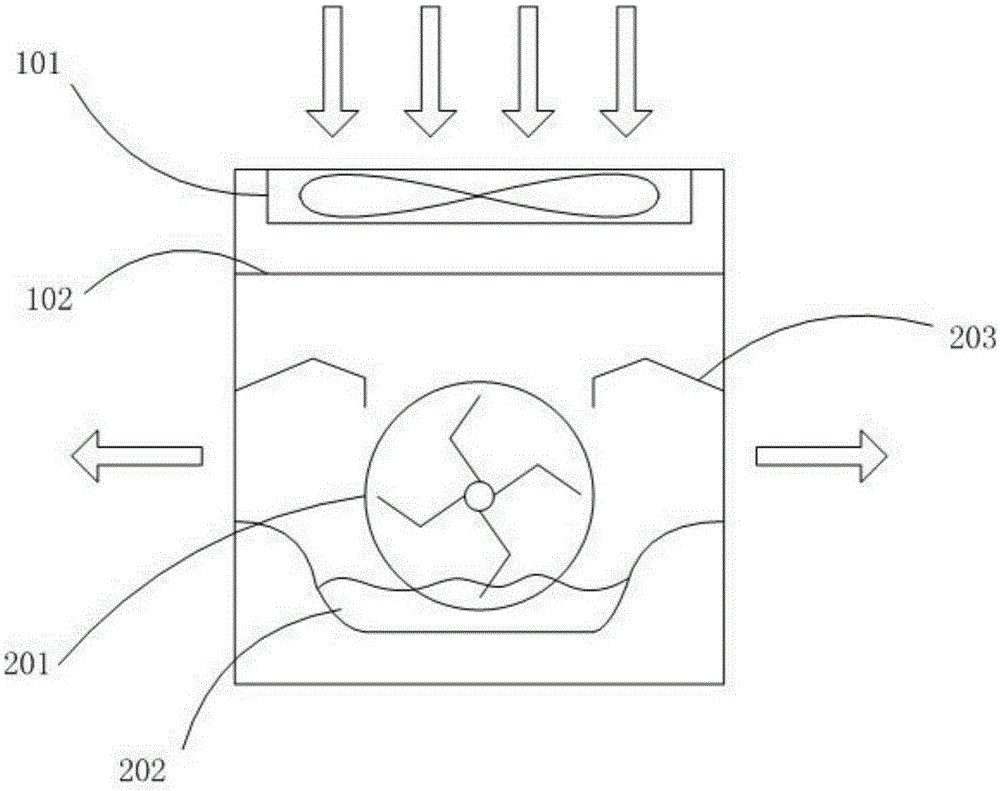

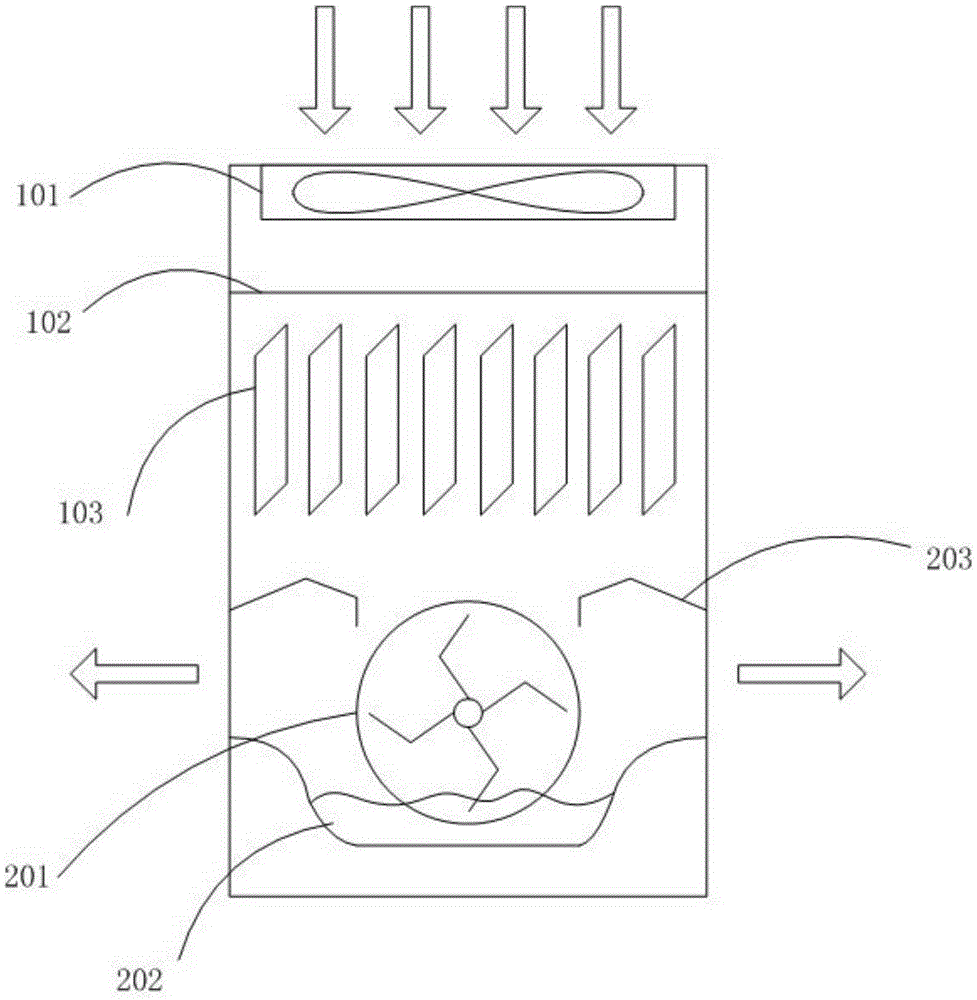

The invention discloses an air cleaner. The air cleaner is characterized by comprising a plasma module and a water filter module. The plasma module comprises a discharge electrode which generates plasma through high voltage discharge. The water filter module comprises a humidifying plate and a water tank, wherein part of the humidifying plate is immersed in water and rotates, then air is taken into the water, and the functions of humidifying and filtering are achieved. By means of the air cleaner, the plasma generated through electric discharge is combined with the water filtering so that the humidified air can carry rich negative oxygen ions; the plasma can achieve the effects of sterilization and disinfection, effectively remove volatile organic compounds and allow dust particulate matter to be charged and accumulated, so that the water filtering efficiency is greatly improved, and the water changing period is prolonged.

Owner:XI AN JIAOTONG UNIV

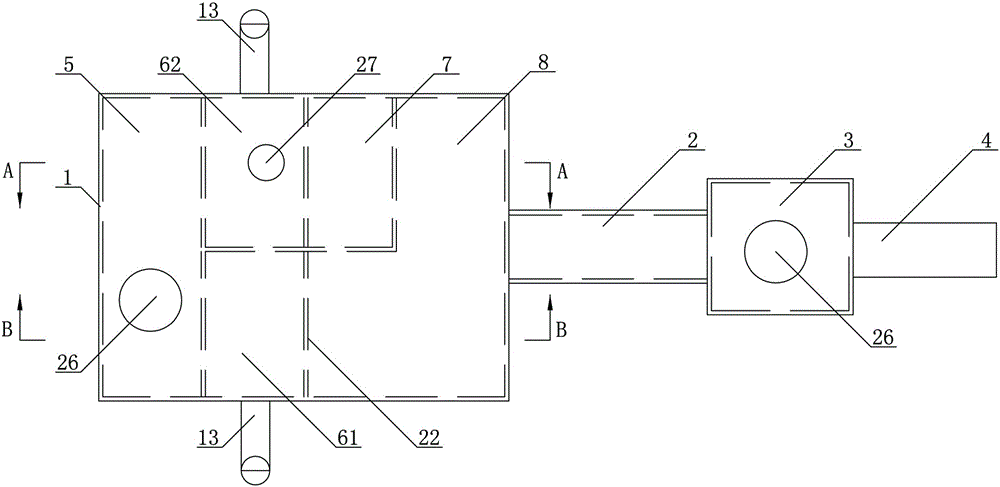

Insulation oil vacuum adsorption regeneration comprehensive treatment system and application thereof

PendingCN107216939AImprove processing efficiencyEnsure safe and stable operationLubricant compositionLow inputSites treatment

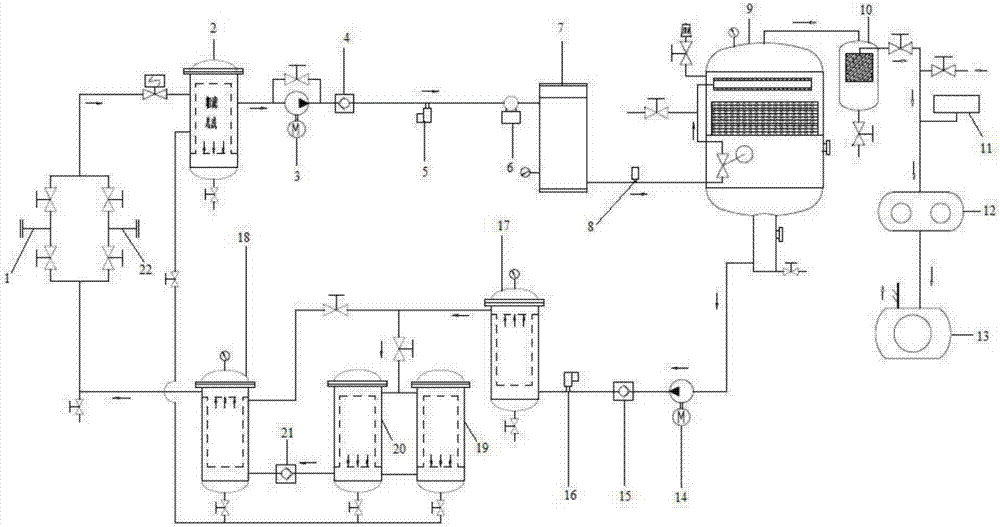

The invention discloses an insulation oil vacuum adsorption regeneration comprehensive treatment system. The insulation oil vacuum adsorption regeneration comprehensive treatment system is characterized in that the output end of an oil inlet is communicated and connected with the input end of a primary filter; the output end of the primary filter is communicated and connected with the input end of a heater; the output end of the heater is communicated and connected with the input end of a vacuum separator; the gas output end of the vacuum separator is communicated and connected with the input end of a steam and water separator; the output end of the steam and water separator is communicated and connected with the input end of a Roots pump; the output end of the Roots pump is communicated and connected with the input end of a vacuum pump; the oil output end of the vacuum separator is connected with the input end of a fine filter; the output end of the fine filter is connected with the input ends of regeneration filters which are connected in parallel; the output end of each regeneration filter is communicated and connected with the lower input end of the fine filter; the output end of the fine filter is communicated and connected with an oil outlet. The insulation oil vacuum adsorption regeneration comprehensive treatment system has the advantages that the harmful matters of corrosive sulfur, dissolved copper, aged product and the like in the insulation oil can be removed, the site treatment efficiency of transformer oil is improved, and the safe and stable running of a transformer is powerfully guaranteed.

Owner:STATE GRID CORP OF CHINA +2

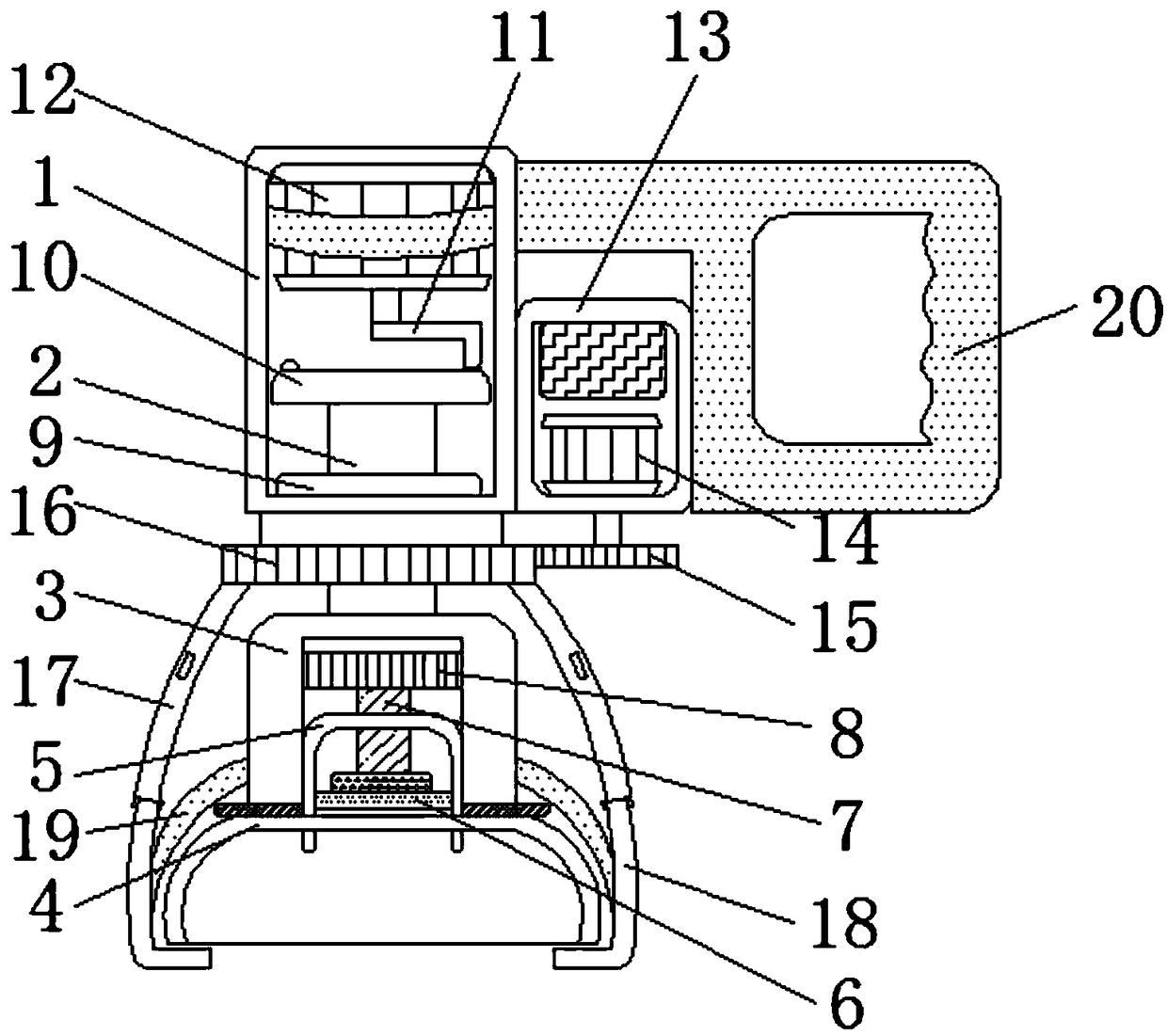

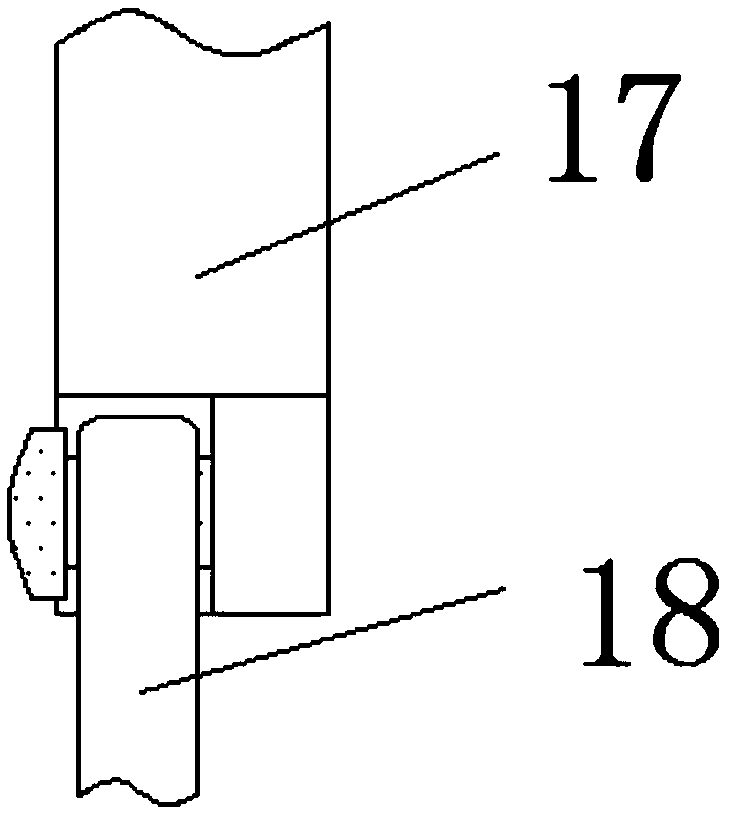

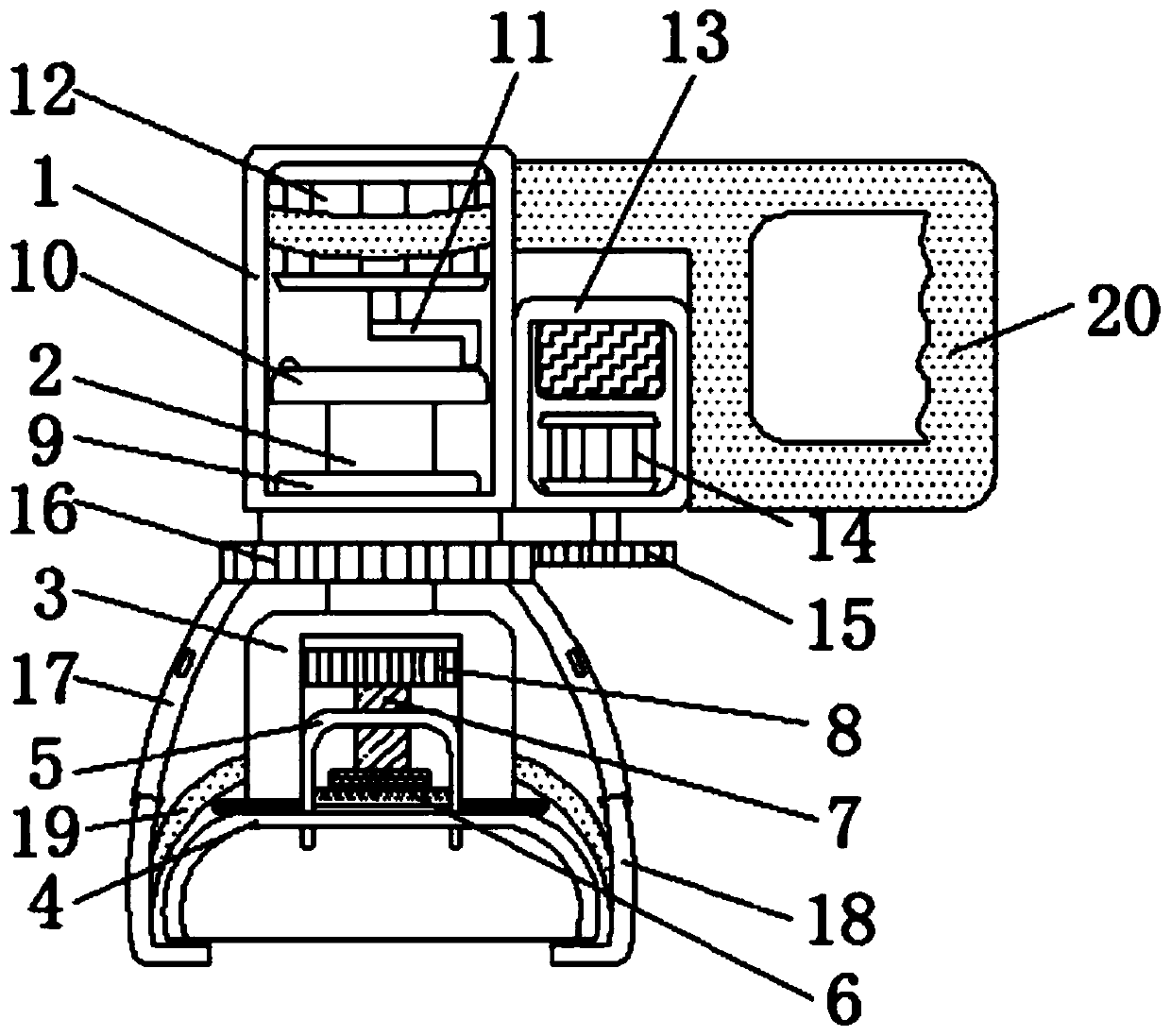

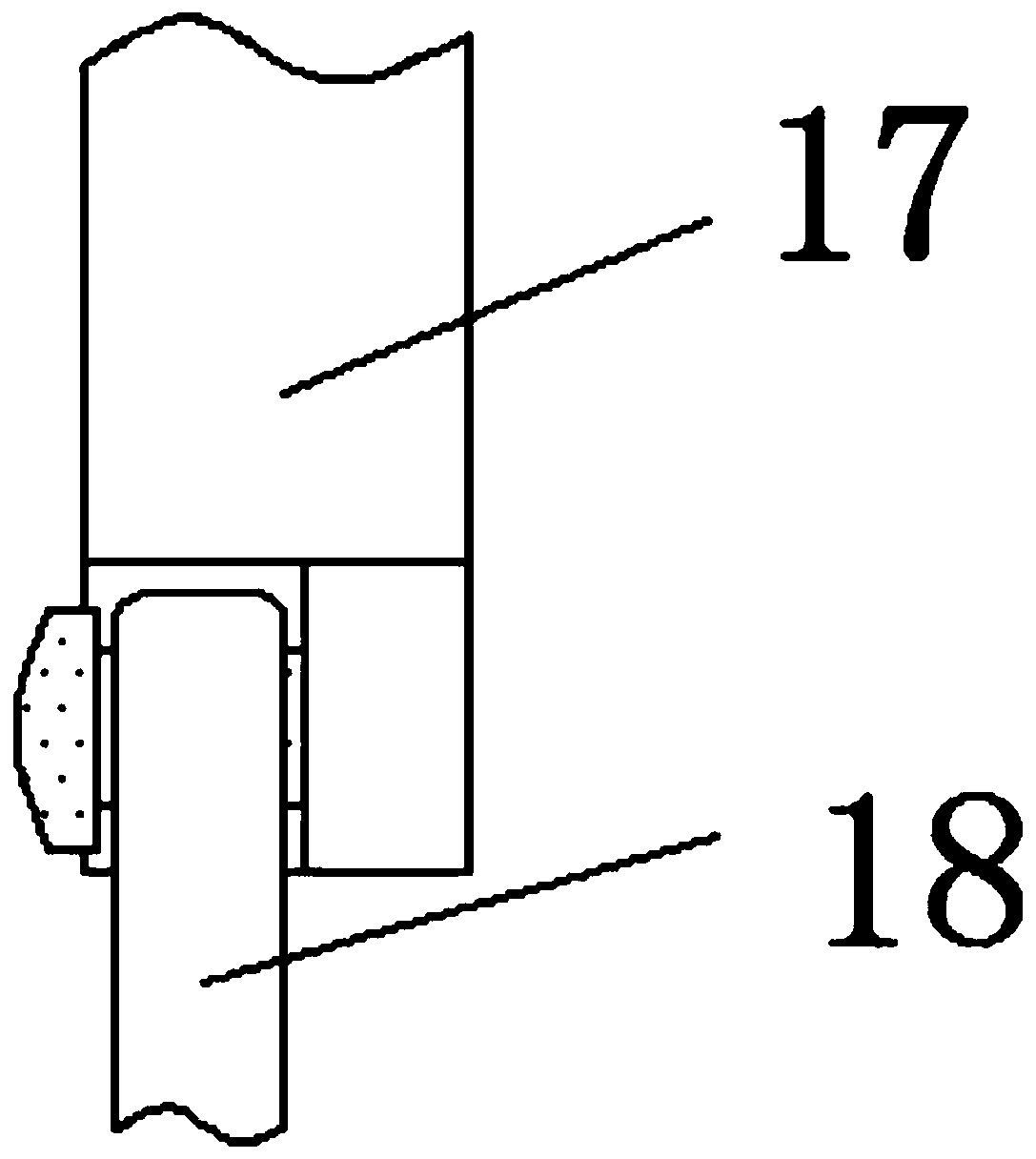

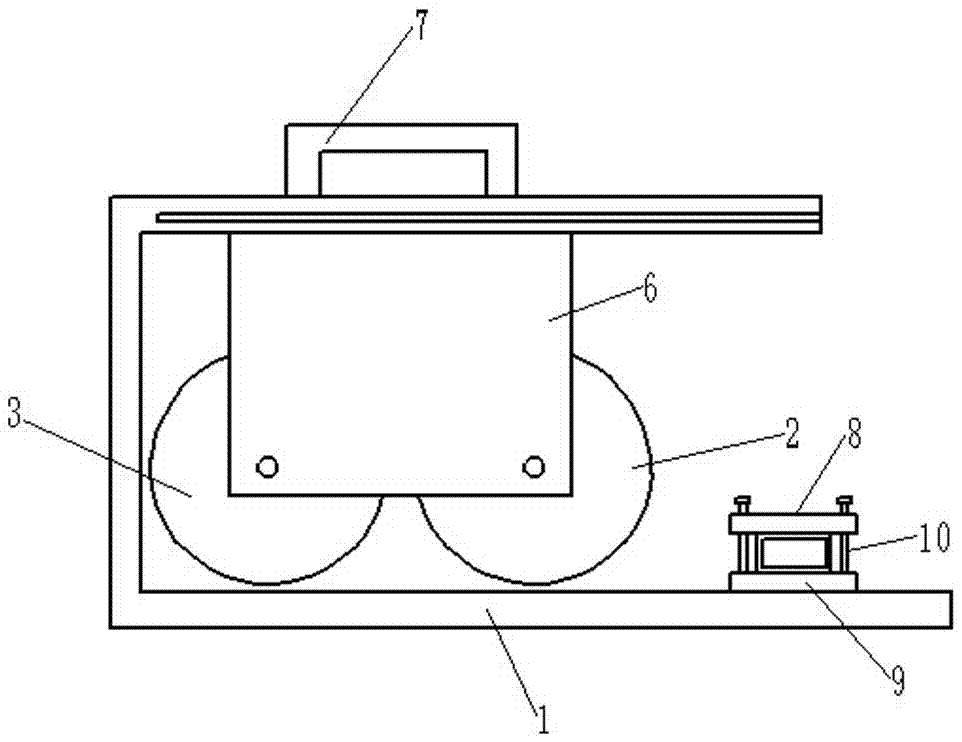

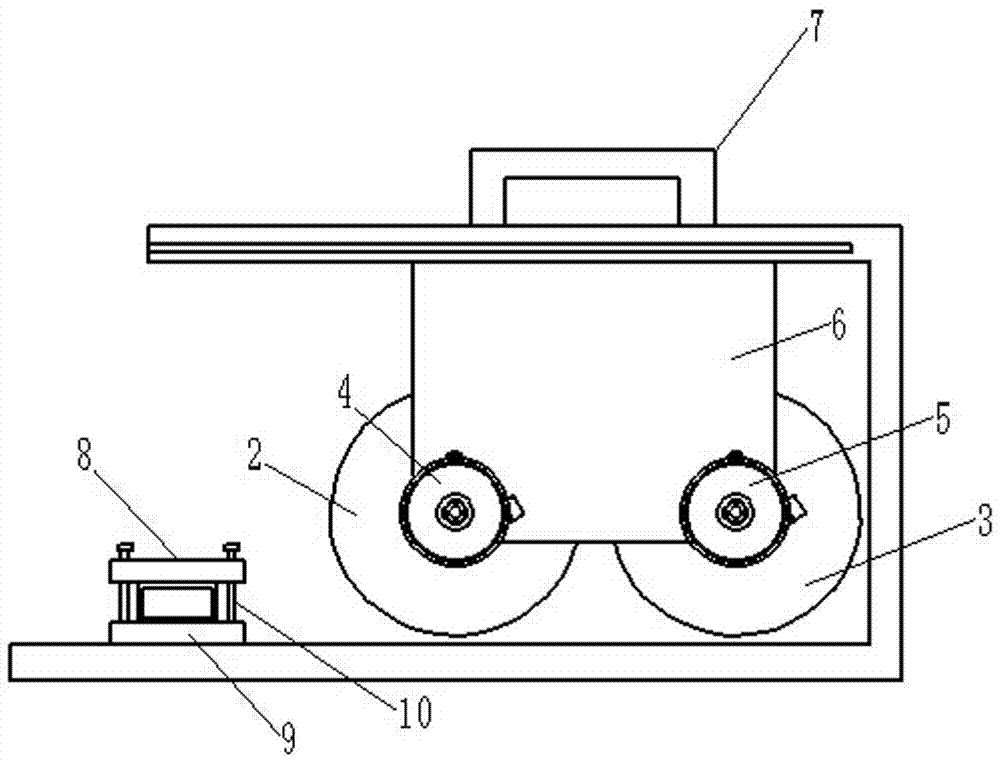

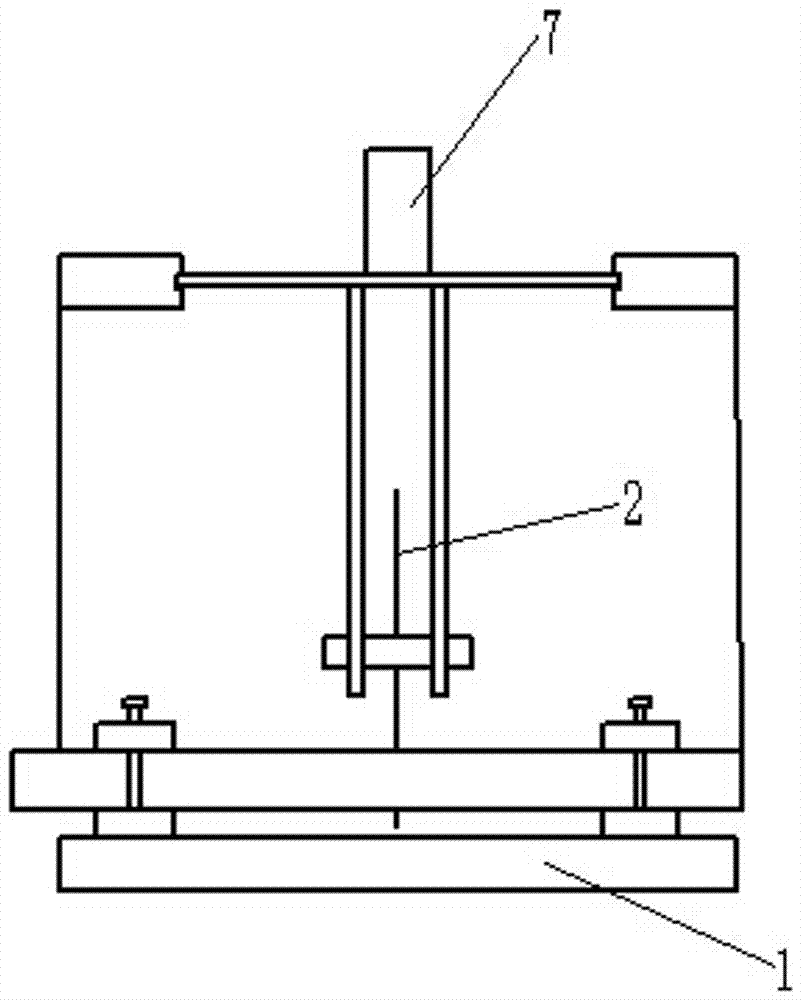

Ice block removing device in refrigerator with reciprocating vibration mode

ActiveCN109297241AChange state of motionImprove adsorption capacityLighting and heating apparatusDefrostingEngineeringRefrigerated temperature

The invention provides an ice block removing device in a refrigerator with a reciprocating vibration mode, and relates to the field of articles for daily use. The ice block removing device in the refrigerator with the reciprocating vibration mode comprises a fixed left box, a reciprocating driving rod is arranged at the bottom of the fixed left box, the bottom of the reciprocating driving rod is adhered to the top of a side control fixed cylinder, the bottom of the side control fixed cylinder is adhered to the top of a connecting sucker, and a right box and a grabbing handle are adhered to theright side of the fixed left box. The ice block removing device in the refrigerator with the reciprocating vibration mode, after the connecting sucker is adsorbed on the ice surface, a driving motoris used for controlling a poking rod to be in contact with convex particles, so that the connecting sucker can continuously vibrate in a reciprocating mode after being connected with the ice blocks, the vibration force formed by vibration is used for gradually reducing the bonding force between the ice blocks and the inner wall of the refrigerator, so that the ice blocks can be removed conveniently, no force is applied to the refrigerator without being in contact with the refrigerator, so that the traditional mode of removing ice by scraping or heating is avoided, the damage to the refrigerator is avoided, and the service life of the refrigerator is guaranteed.

Owner:邵帅

Method for preparing citrus dietary fiber

The invention discloses a method for preparing citrus dietary fiber, which comprises pretreatment, cooking, chemical modification, purification, homogenization and spray drying. The process steps of the invention cooperate with each other, the impurities can be removed at an early stage, and the yield of dietary fiber is improved by high temperature and high pressure strong acid steaming, in a middle stage, impurities such as undecomposed organic matter, larger-diameter cellulose, and acid-base salt are removed by filtering and alcohol precipitation, in a later stage, chemical modification andhomogenization improve the quality of dietary fiber, the water retention is improved, and the high-yield and high-quality dietary fiber can be obtained, the process design is reasonable, and the comprehensive cost is low.

Owner:广州市莱檬生物科技有限公司 +3

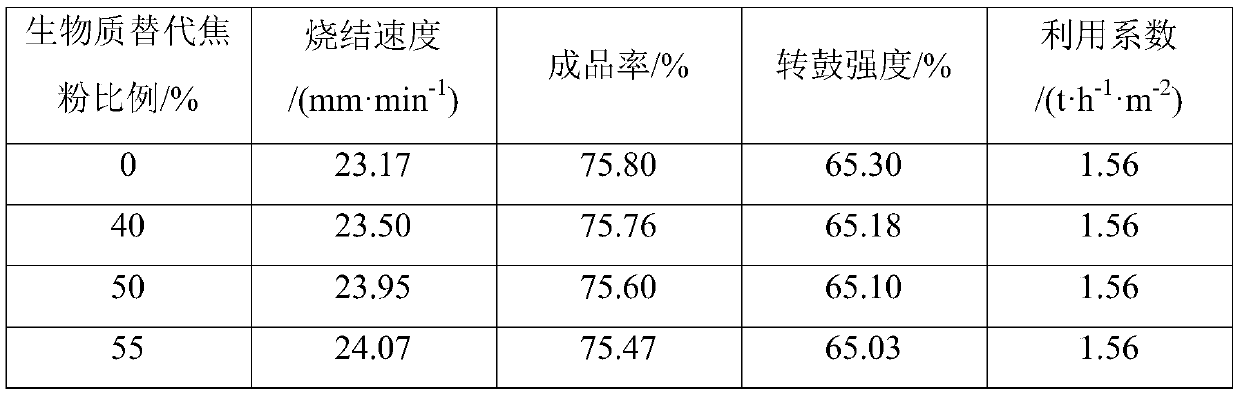

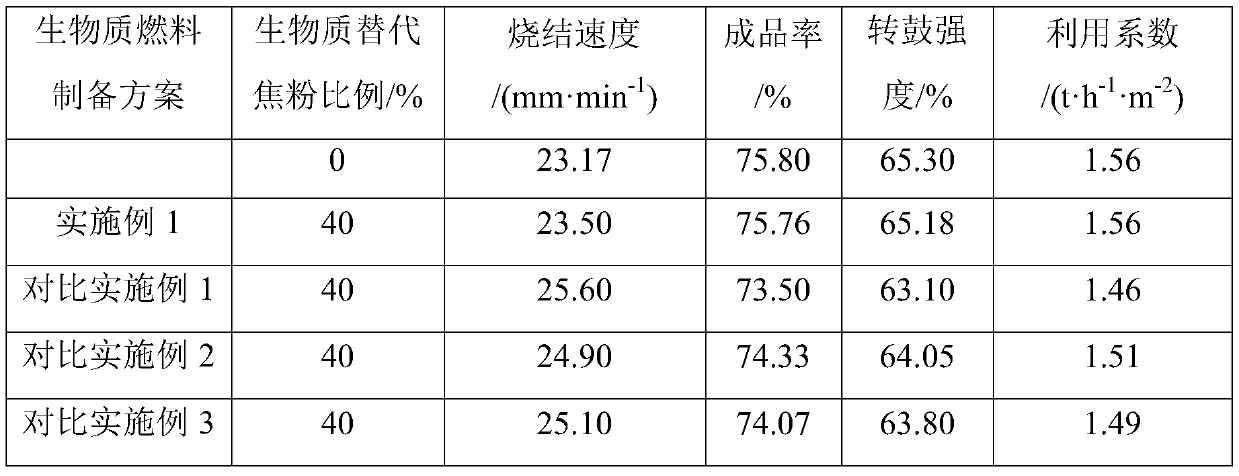

Iron ore sintered biomass fuel and preparation method and application thereof

The invention discloses an iron ore sintered biomass fuel and a preparation method and application thereof. The preparation method comprises the steps that biomass powder is mixed with iron selectingtailing slag-silica tailing slag mixed powder and then are pressed into biomass particles; and the biomass particles are placed in a protective atmosphere and then subjected to low-temperature pretreatment and high-temperature carbonization treatment in sequence to obtain high quality biomass fuel with heat value of 26-33MJ / kg, volatile content of 0.5-3%, specific surface area of 10-25m<2> / g, porosity of 15-25%, apparent density of 1.5-2.2g / cm<3>. According to the iron ore sintered biomass fuel, the combined effects of inert components SiO2 in ore slag to weaken the thermochemical reaction activity of the biomass fuel and iron oxides to promote the efficient cracking of volatiles are fully utilized, and can replace the use of biomass fuel of fossil fule with high proportions to achieve efficiently reducing the emission of SOx, NOx and CO2 from the source.

Owner:CENT SOUTH UNIV

Method for preparing composite ammonia nitrogen remover and application thereof

The present invention provides a preparation method for remover for compound ammonia nitrogen, which is developed aiming at the defects of utilizing the biological method and the aeration stripping method to apply the treatment to the ammonia nitrogen in the sewage that the technological process is long and the removal rate is not high. The preparation method for remover for compound ammonia nitrogen comprises the following steps: first the mixture of the phosphates and the magnesium salts is remixed; wherein the mixing is carried out following the molar ratio ranging from 1.0:1.0 to 1.3:1.0 according to Mg2+:PO42- and the mixture is mixed with the water in a mass ratio of 1:9 so as to be dissolved into the solution, and then the solution containing ferrous acids which the acidity (calculated according to the content of HCl) ranges from 10% to 50%, the content of Fe3+ ranges from 0.05% to 5% and the content of Fe2+ ranges from 8% to 8% in is added in the solution and the homogeneous solution is obtained under the sufficient stirring. A liquid ammonia nitrogen treatment agent prepared according to the present invention has simple manufacturing technique, is beneficial to the transportation and adding, has very strong ability of removing the ammonia nitrogen, is suitable for removing the ammonia nitrogen in the industrial sewage and domestic sewage of various industries, in particular the printing and dyeing, chemical engineering, paper making industries, etc and simultaneously has the auxiliary effect of removing the phosphorus ions in the sewage and lower COD.

Owner:CHANGZHOU WUJIN YOUBANG WATER PURIFICATION MATERIALS

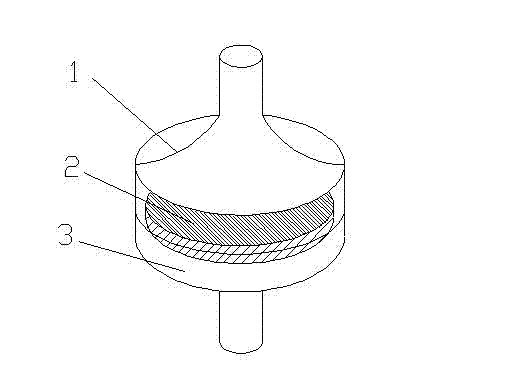

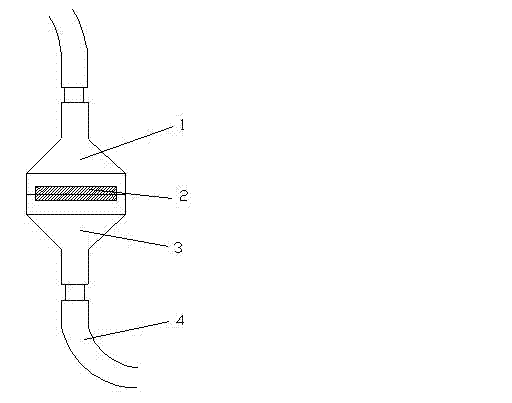

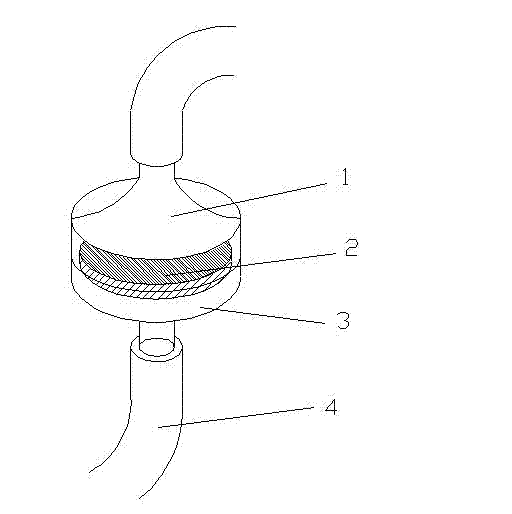

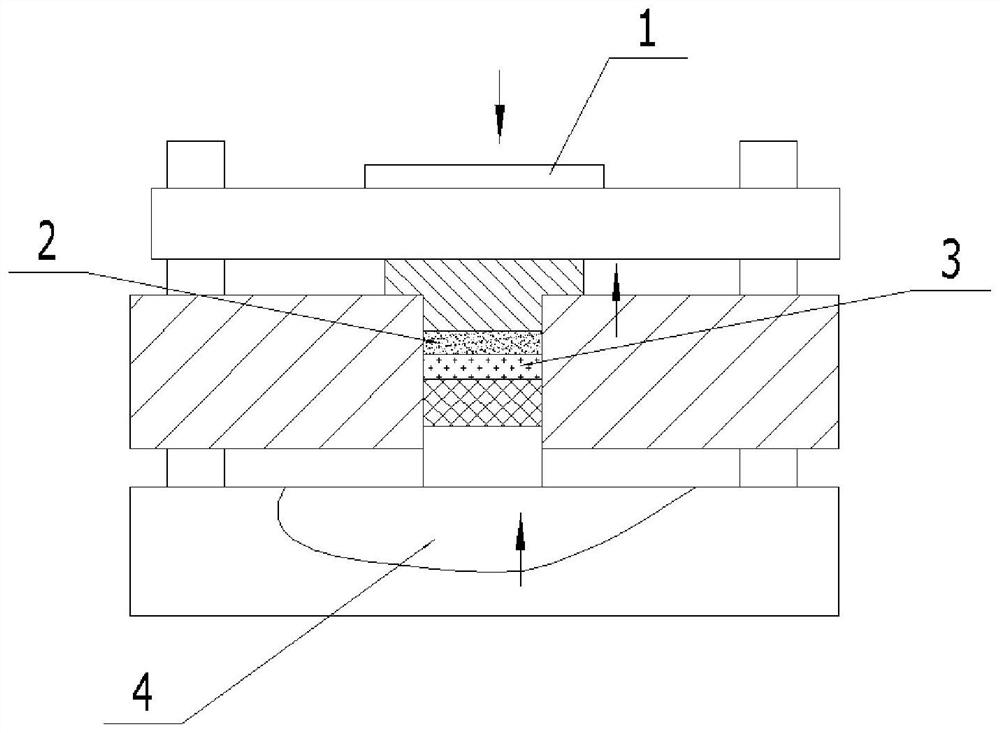

Filtration apparatus for removing leucocytes from plasmodium-infected blood

InactiveCN102357319ARemove helpNovel filter materialGravity filtersStationary filtering element filtersWhite blood cellFiltration

The present invention discloses a filtration apparatus for removing leucocytes from plasmodium-infected blood. The filtration apparatus comprises a filter assembly and a filter core. The filter assembly comprises two filter components of an upper filter component and a lower filter component, wherein the two filter components have the same shapes, which are bellmouth-shaped. The filter core is arranged between the upper filter component and the lower filter component. The filtration apparatus provided by the present invention has the following advantages that: the used filter material is novel; the effect is definite; the filter design is scientific and reasonable; the filter method is practical and convenient; with the apparatus, efficient removal of the leucocytes in the sample can be ensured, the most of the purified plasmodium-infected erythrocytes can be concurrently recovered.

Owner:陶志勇 +1

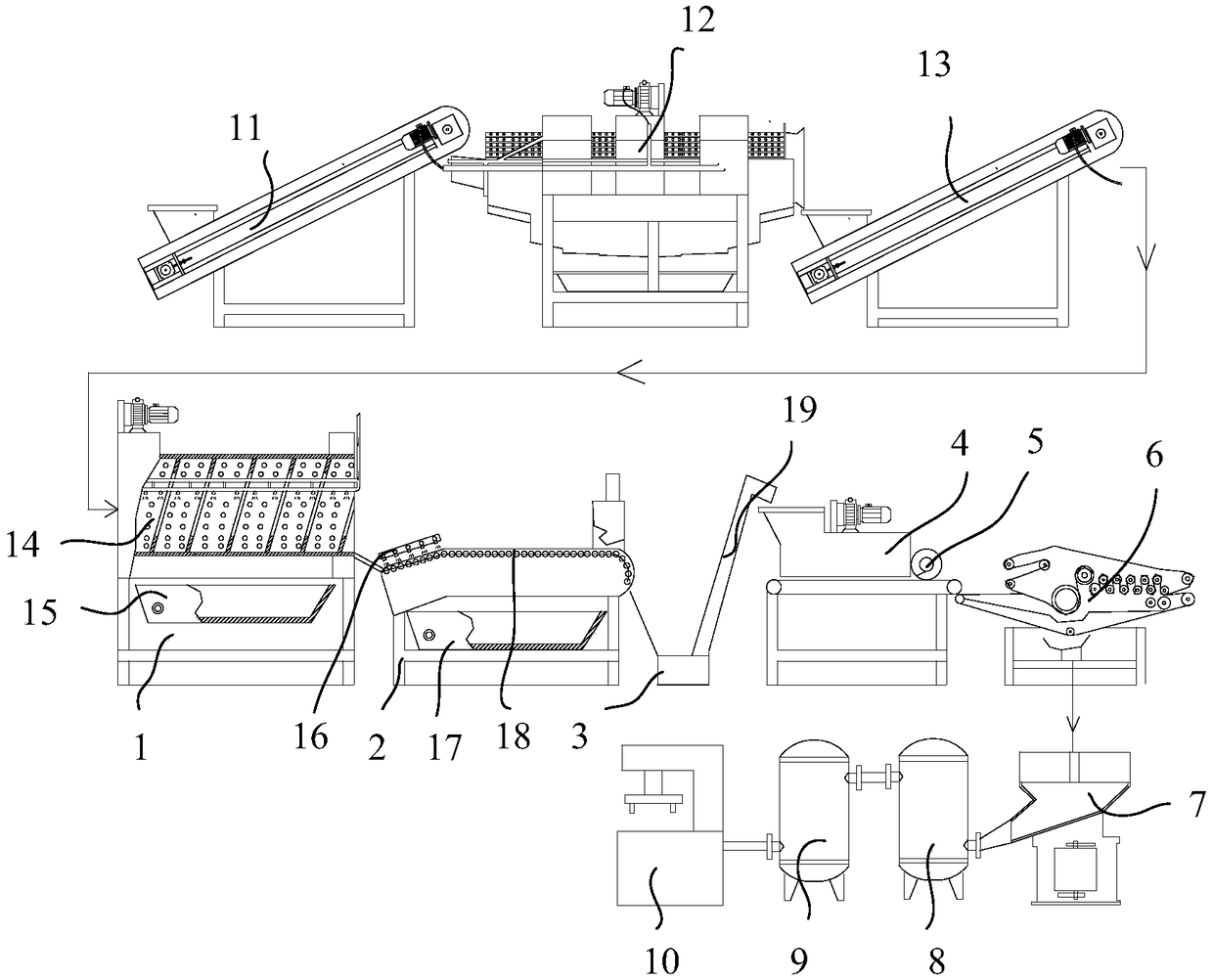

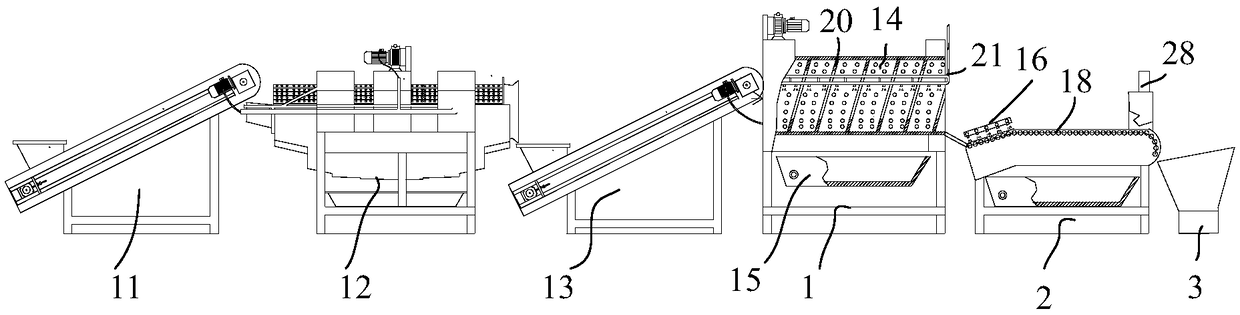

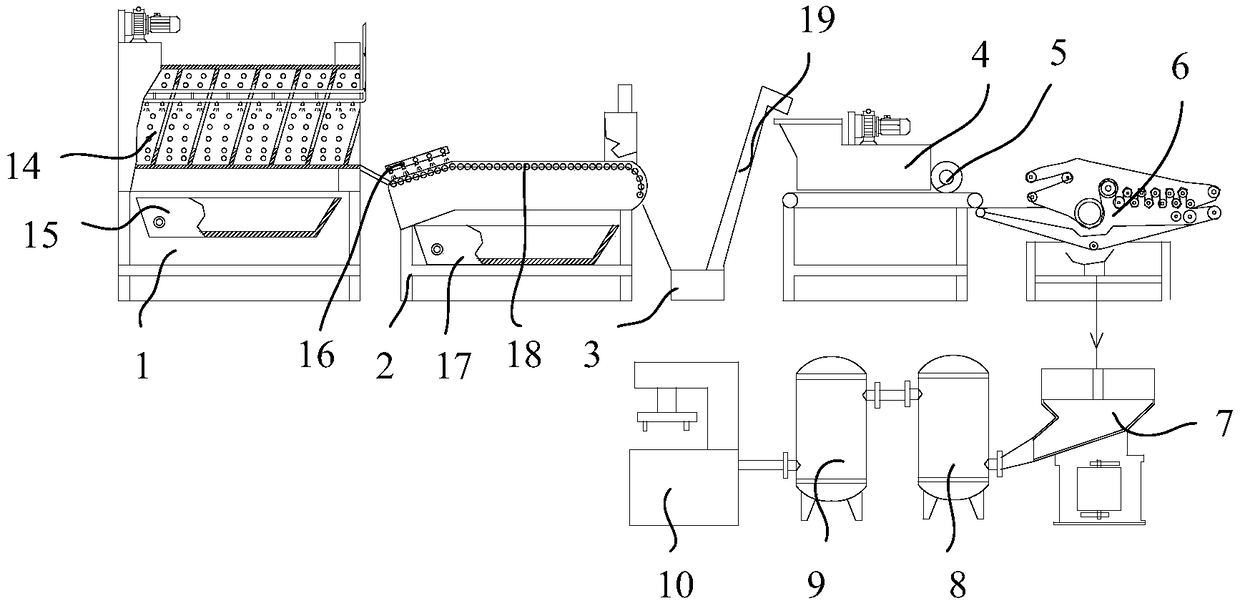

Roxburgh rose juicing system

PendingCN108926005AWon't hurtEfficient separationJuice extractionFood treatmentFruit juiceBuffer tank

The invention relates to a roxburgh rose juicing system. The roxburgh rose juicing system comprises a thorn removing device, a rotary drum cleaning machine, a cleaning conveyor, a water tank, a hammercrusher, a distributor, a belt filter press, a vibrating filter, a buffer tank, a high-temperature sterilization device and a can filler which are sequentially connected. A plurality of thorn removing rods are arranged on the inner side wall of a rotary drum body of the thorn removing device, and a spirally arranged screw conveyor is arranged on the inner side wall of the rotary drum body; an inner screw conveyor is spirally arranged on the inner side wall surface of a cleaning rotary drum, a first spraying device extends into the cleaning rotary drum, a winnower is arranged at one end, closeto the hammer crusher, of the cleaning conveyor, and a winnower air outlet opposite to the material conveying direction of the cleaning conveyor is formed in the winnower. By the aid of the juicing system, thorns of roxburgh rose fruits are removed mechanically, the cleaning cleanliness before juicing is high, rot individuals mixed in the roxburgh rose fruits are removed, juicing materials are fed uniformly, the automation degree of the whole system is higher, roxburgh rose fruit juice with good quality and low impurity content can be obtained, and canned storage of the juice is realized.

Owner:贵州宏财聚农投资有限责任公司

Device and method for removing ice cubes in refrigerator by means of reciprocal vibration

InactiveCN111578602AChange state of motionImprove adsorption capacityLighting and heating apparatusDefrostingIceboxStructural engineering

The invention provides a device and method for removing ice cubes in a refrigerator by means of reciprocal vibration, and relates to field of articles of daily use. The device for removing the ice cubes in the refrigerator by means of reciprocal vibration comprises a left fixed box, wherein a reciprocating driving rod is arranged at the bottom of the left fixed box, the bottom of the reciprocatingdriving rod is bonded to the top of a side hollow fixed cylinder, the bottom of the side hollow fixed cylinder is bonded to the top of a connecting suction cup, and a right mounting box and a grabbing handle are bonded to the right side of the left fixed box. According to the device for removing the ice cubes in the refrigerator by means of reciprocal vibration, after the connecting suction cup is sucked on the ice surface, a driving motor controls a stirring rod to be in contact with protrusion particles, so that the connecting suction cup constantly makes reciprocal vibration after being connected with the ice cubes, and vibration force generated through vibration is utilized for gradually lowering the bonding force between the ice cubes and the inner wall of the refrigerator, which helps to remove large ice cubes. Meanwhile, the ice cubes are not in contact with the refrigerator and do not apply force to the refrigerator either, which avoids the damage to the refrigerator incurredby the traditional mode of ice removal through scraping or heating, and can guarantee the service life of the refrigerator.

Owner:蒋远民

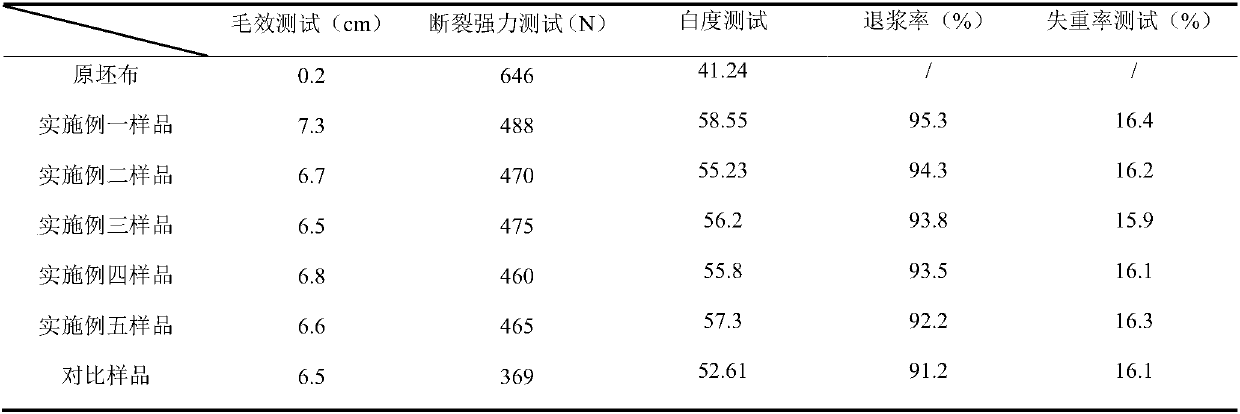

Biological composite enzyme of pretreatment refining process for cotton fabric dyeing and finishing, and pretreatment refining process thereof

InactiveCN107724091AGentle refining processGood hair effectBiochemical treatment with enzymes/microorganismsVegetal fibresPectinaseCellulose

The invention relates to a biological composite enzyme of a pretreatment refining process for cotton fabric dyeing and finishing, and a pretreatment refining process thereof. The biological compositeenzyme is formed by mixing 23.8-27.3 wt% of alpha-amylase, 54.5-71.4 wt% of pectinase and 4.8-18.2 wt% of cellulase. According to the pretreatment refining process, the pH value of a refining solutionis controlled at 7-8, the biological enzyme has good activity at the pH value of 7-8, the refining temperature is controlled at 50-80 DEG C, 2.1-5.5 g / L of the biological composite enzyme is added, 0.5-2.0 g / L of a non-ionic surfactant is added, a cotton fabric is refined for 50-90 min at a bath ratio of 1:(15-35), the refined cotton fabric is rapidly deactivated at a temperature of 100 DEG C after the refining, washing is performed with 95 DEG C hot water, washing is performed with 60 DEG C warm water, washing is performed with cold water, and drying is performed for 2-4 h at a temperature of 80 DEG C. According to the present invention, with the biological composite enzyme and the refining method, the refining quality and the refining efficiency of the biological composite enzyme are effectively improved, the environment pollution is effectively avoided, and the pollution management cost is reduced.

Owner:PUTIAN UNIV

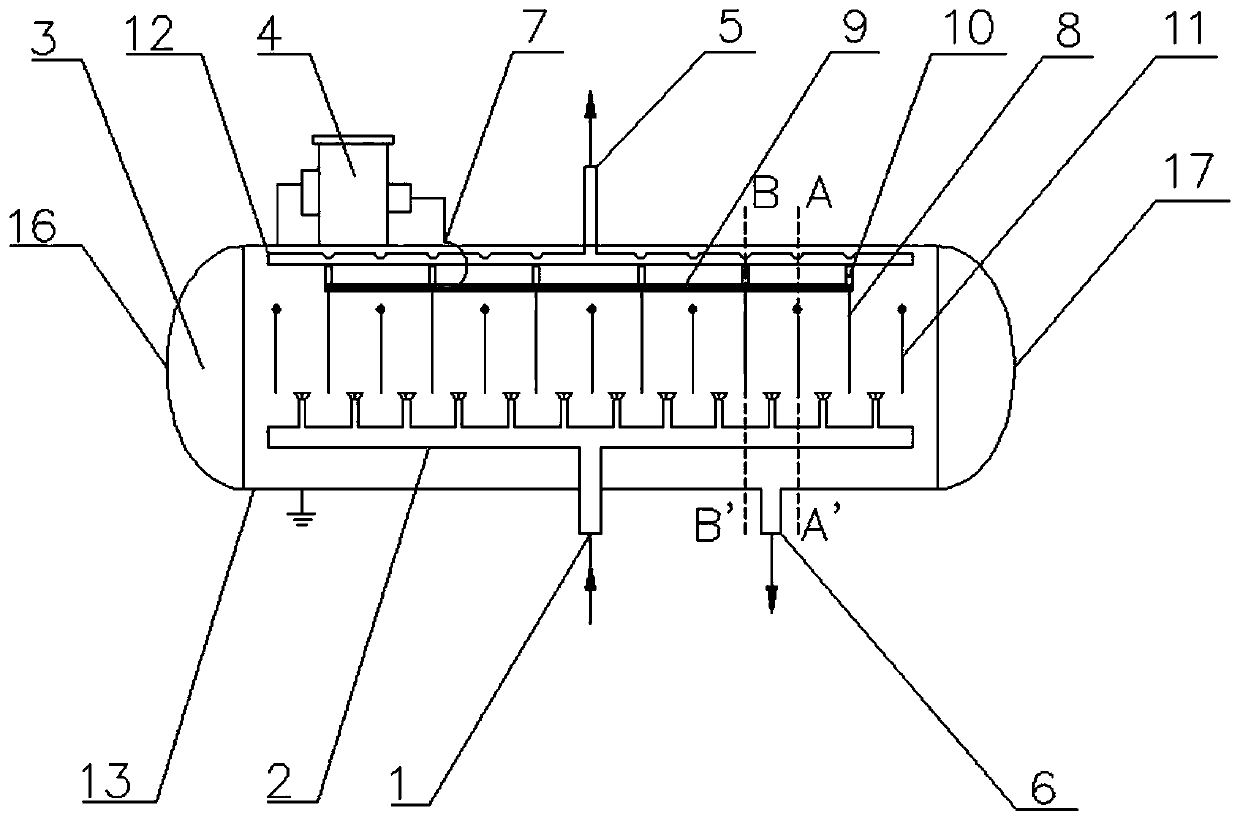

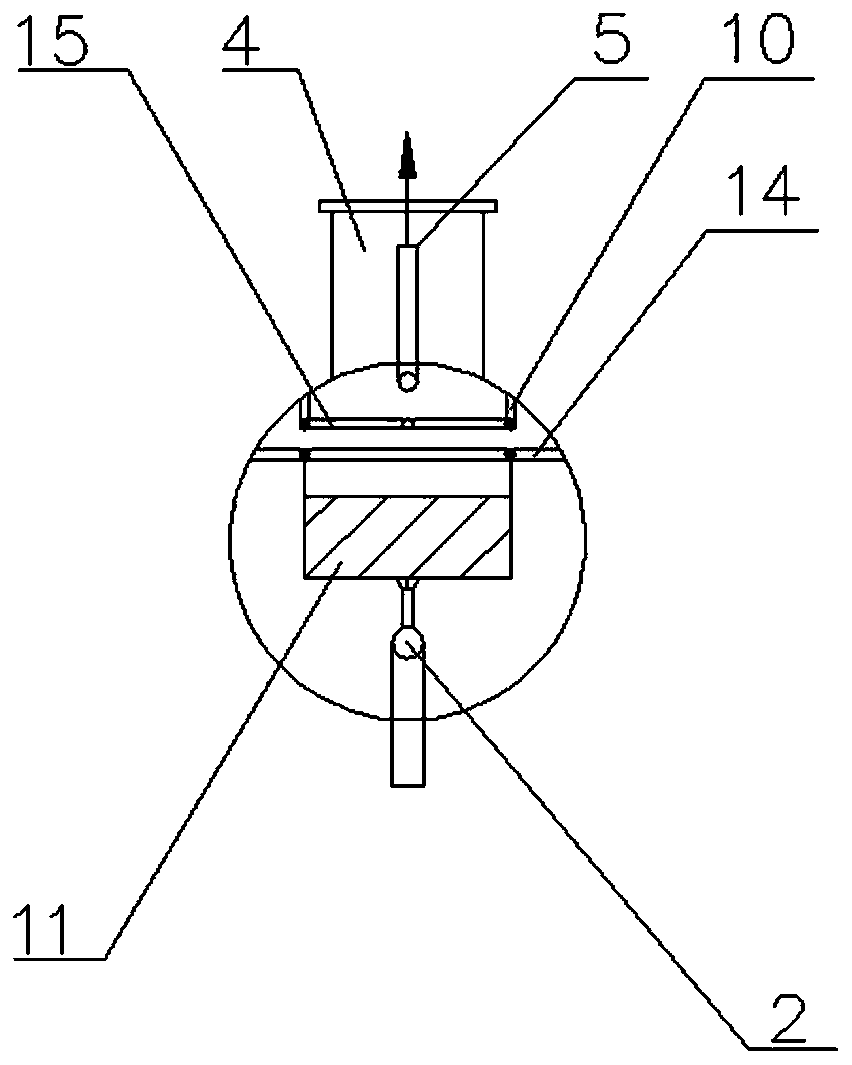

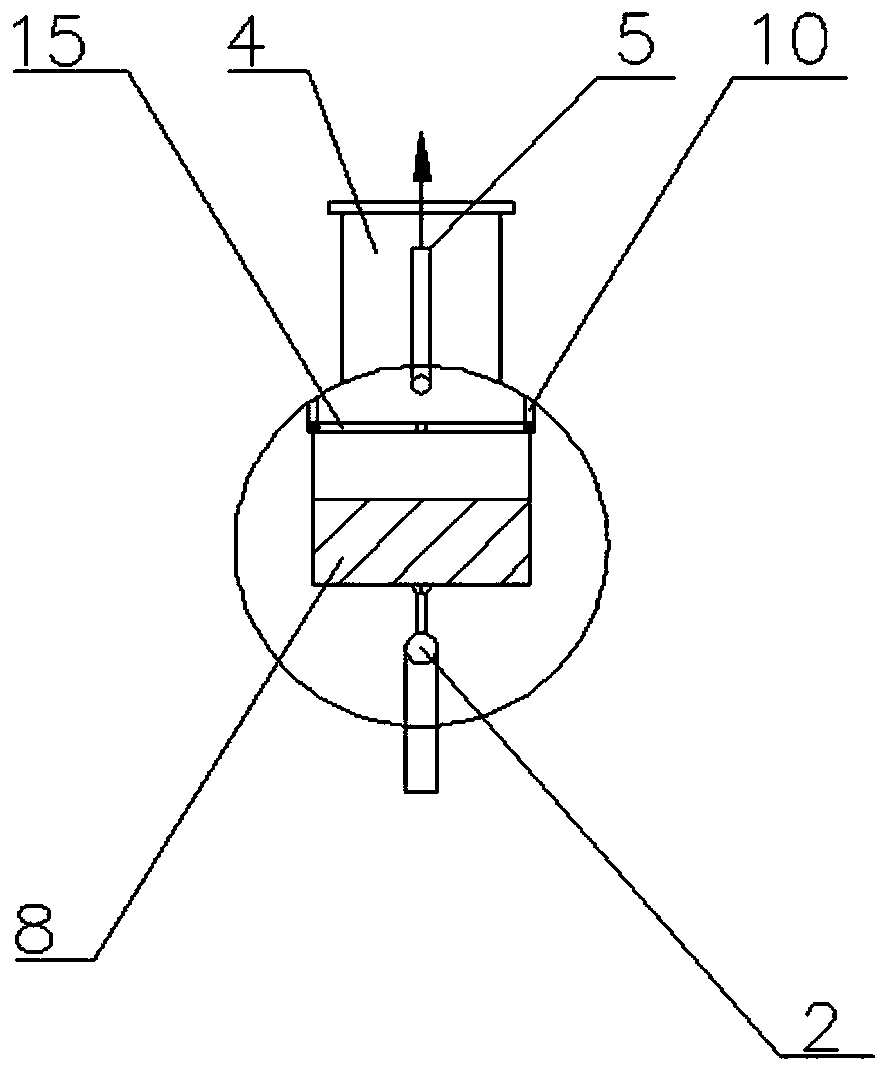

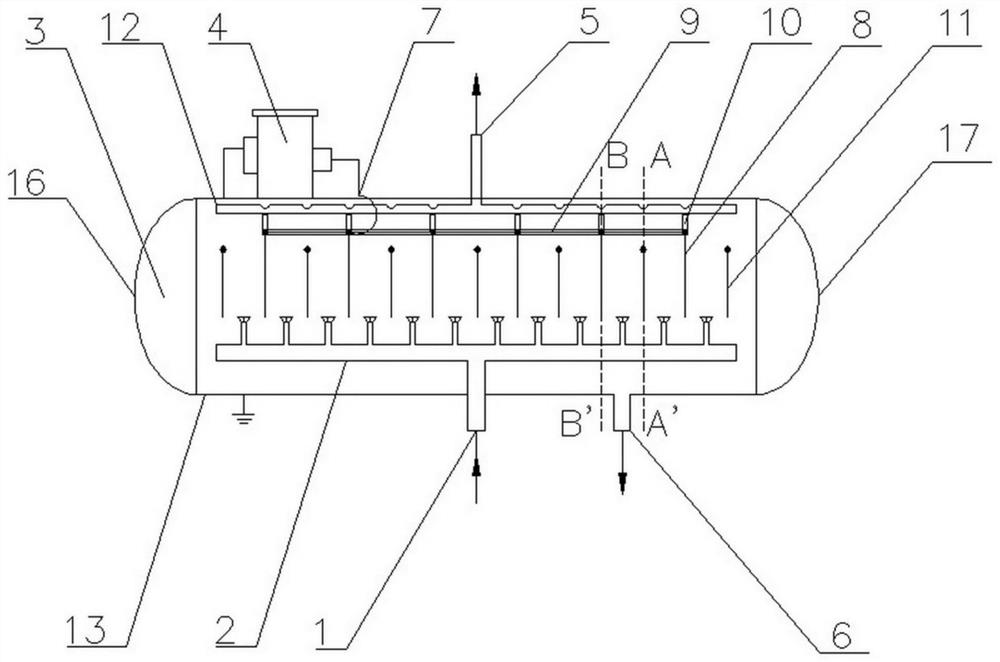

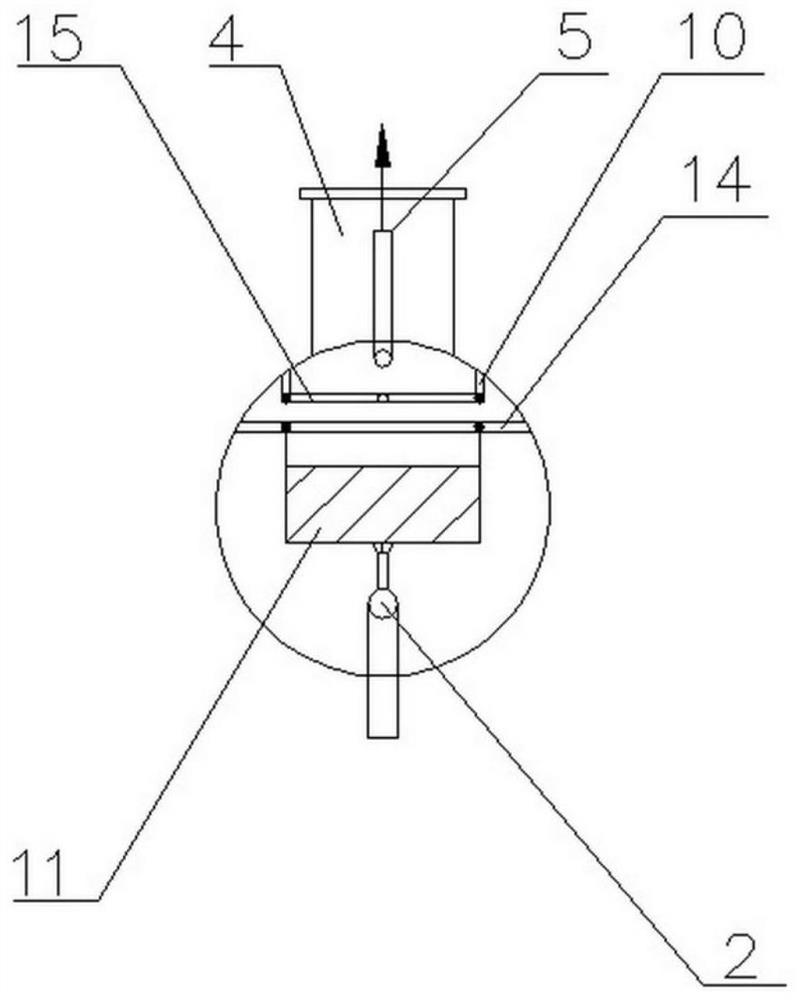

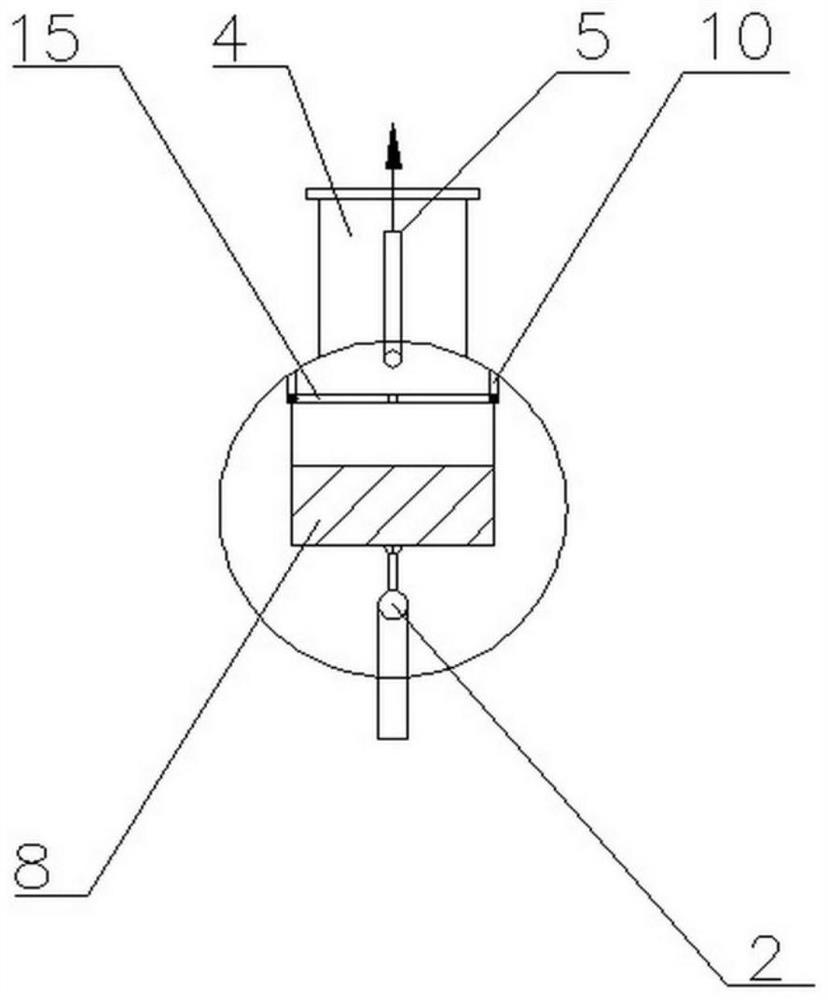

Electrostatic separation device and process for removing solid particles in catalytic cracking slurry oil and slurry oil purification device

ActiveCN111454743AImprove removal efficiencyMeet the requirements of high-purity purificationRefining by electric/magnetic meansHydrocarbon oils treatmentElectrostatic separationPtru catalyst

The invention provides an electrostatic separation device and process for removing solid particles in catalytic cracking slurry oil and a slurry oil purification device, and relates to the technical field of slurry oil purification. The method comprises the following steps: uniformly distributing catalytic cracking slurry oil in a plurality of electrostatic fields through a raw material distributor for a purification treatment so as to remove solid particles in the catalytic cracking slurry oil. Electrostatic field polarization, coalescence, adsorption, sedimentation, feeding distribution, andelectrode plate combined application technologies are adopted, the catalyst solid ultrafine particles are deeply removed, the problem that solid ultrafine particles are difficult to remove through aconventional separation method is solved, and the solid particle removal efficiency is remarkably improved. The provided electrostatic separation device is simple in structure, convenient to operate and suitable for long-period operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of cleaning and micro-etching semiconductor wafers

InactiveCN102157355ALow conductivityLow efficiencySemiconductor/solid-state device manufacturingOrganic non-surface-active detergent compositionsWaferingIngot

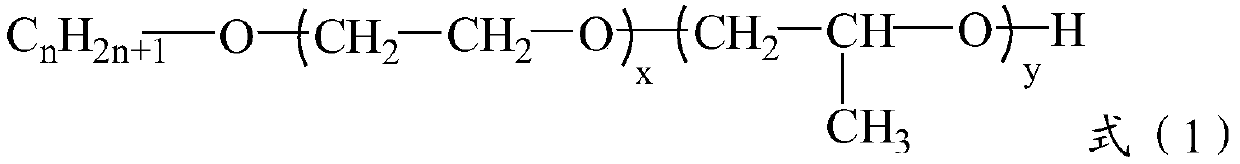

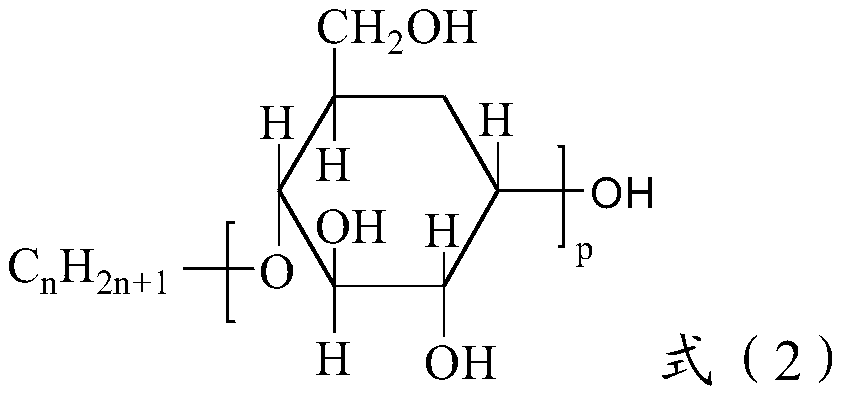

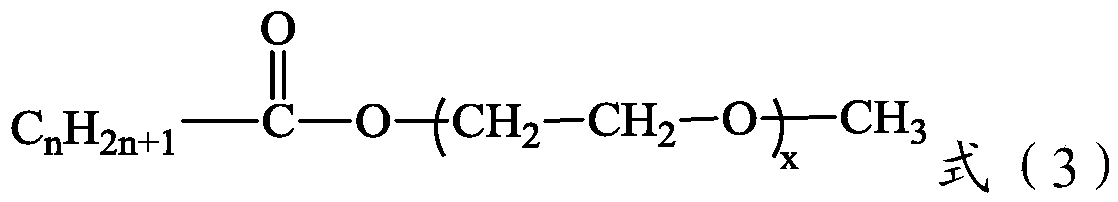

A method of simultaneously cleaning inorganic and organic contaminants from semiconductor wafers and micro-etching the semiconductor wafers. After being cut or sliced from ingots, semiconductor wafers are contaminated with cutting fluid as well as metal and metal oxides from the saws used in the cutting process. Aqueous alkaline cleaning and micro-etching solutions containing alkaline compounds and mid-range alkoxylates are used to simultaneously clean and micro-etch the semiconductor wafers. The method provided includes the steps of a) providing semiconductor ingots; b) cutting the semiconductor ingots to form one piece or pieces of semiconductor wafers containing inorganic and organic contaminants; and c) applying an aqueous alkaline solution comprising one or more quaternary ammonium hydroxides, one or more alkali hydroxides and one or more mid-range alkoxylates in sufficient amounts to remove the contaminants and micro-etch the semiconductor wafers.

Owner:SUN CHEM CORP

Tail gas treatment device

InactiveCN110917854AAvoid cloggingAvoid removalGas treatmentDispersed particle separationEngineeringSpray tower

The invention relates to the field of semiconductor production, in particular to a tail gas treatment device. The tail gas treatment device comprises a water tank which is divided into a negative pressure cavity and a normal pressure cavity, and the negative pressure cavity is provided with an air inlet and a channel; a spray tower internally provided with a water spray port and an alkali liquor spray port, wherein the bottom of the spray tower is connected with the channel of the negative pressure cavity, an air outlet is formed in the top of the normal pressure cavity, a water outlet is formed in the bottom of the normal pressure cavity, the normal pressure cavity is connected with the spray tower through a venturi tube, and the venturi tube is used for conveying gas in the spray tower to the normal pressure cavity and exhausting the gas from the air outlet; and a variable-frequency fan used for conveying water in the normal pressure cavity into the venturi tube to form negative pressure. The tail gas treatment device is good in tail gas treatment effect, not prone to causing blockage and long in maintenance period, and the maintenance cost is reduced.

Owner:XIAN ESWIN MATERIAL TECH CO LTD +1

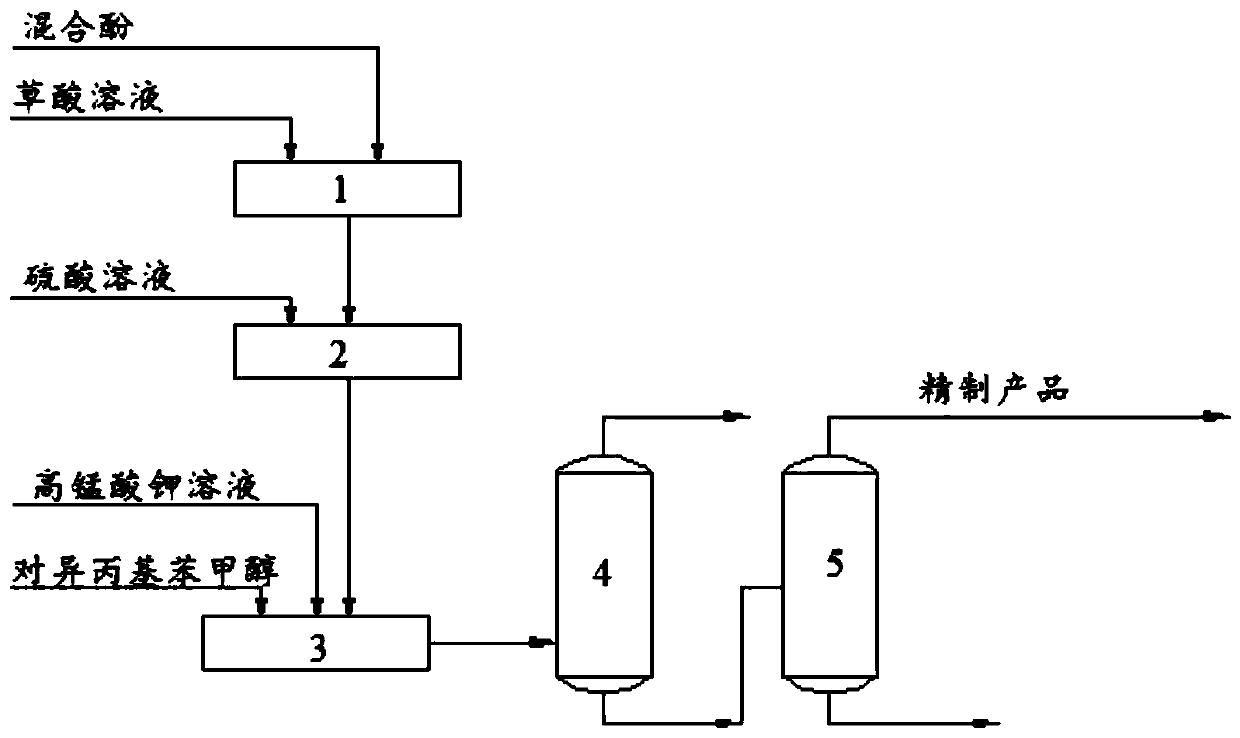

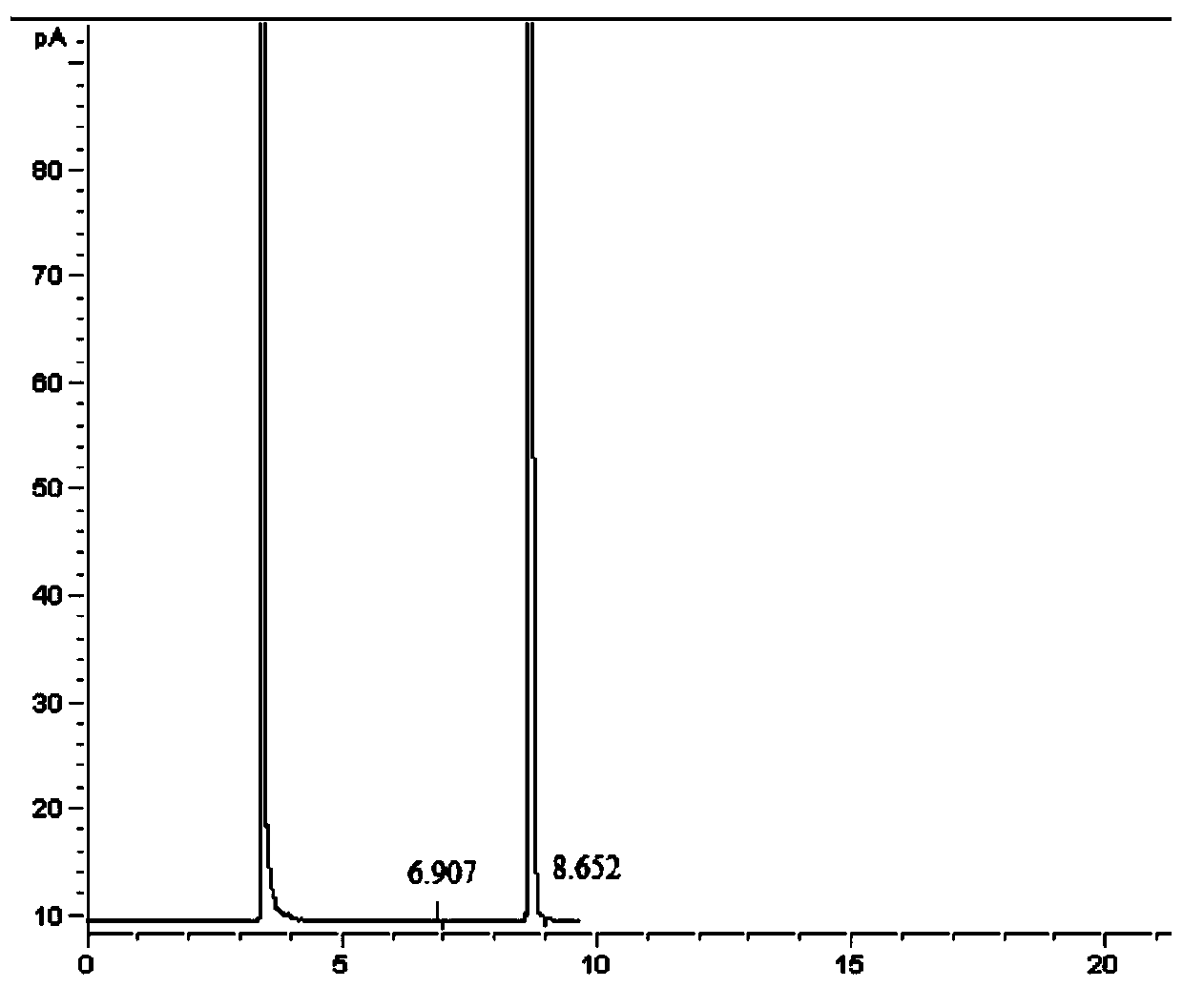

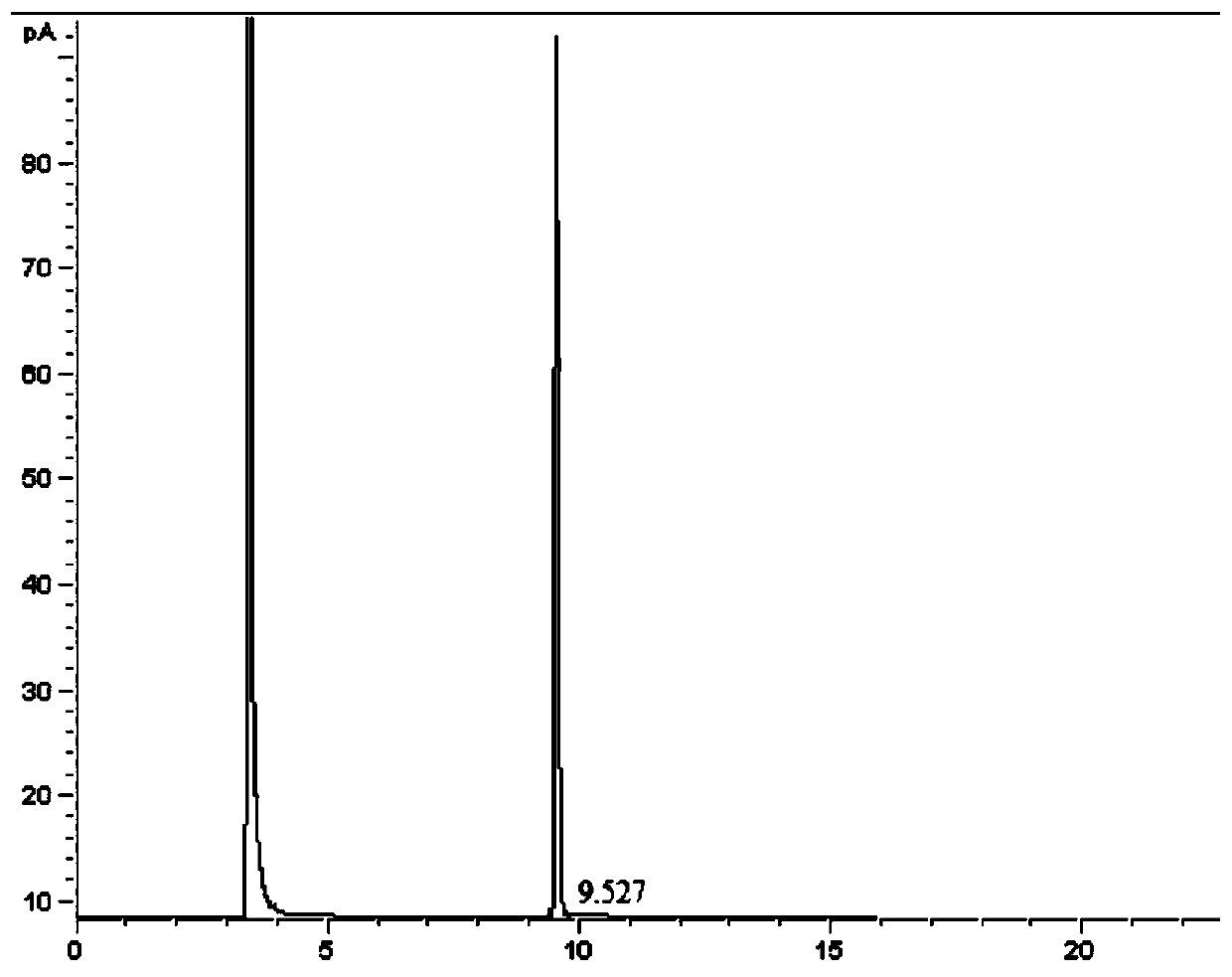

Method for removing pyridine base in mixed phenol

ActiveCN110759816AImprove removal effectRemove helpOrganic chemistryOrganic compound preparationOXALIC ACID DIHYDRATEPyridine

The invention belongs to the technical field of the coal chemical industry, and particularly relates to a method for removing pyridine base in mixed phenol. The method comprises the steps of: performing a first reaction of the mixed phenol and oxalic acid solution to obtain a first intermediate product; performing a second reaction of the first intermediate product and sulfuric acid solution to obtain a second intermediate product; performing a third reaction of the second intermediate product and potassium permanganate solution to obtain a third intermediate product; and after rectifying thethird intermediate product, obtaining the refined mixed phenol. According to the method, three substances of oxalic acid, sulfuric acid and potassium permanganate sufficiently take a synergistic effect and are mutually and progressively removed in a classified mode so as to obtain the refined mixed phenol; after rectification, purity of the refined mixed phenol can reach over 99.9%, and content ofthe pyridine base is smaller than 0.005%, so that quality of the product is improved; and the refined mixed phenol is stable in color and difficult to discolor. By the method, impurities in the mixedphenol, such as organic nitrogen, organic sulfur and the like, also can be removed. Moreover, the method is simple in production process, convenient to operate and easy to implement.

Owner:SHAANXI COAL & CHEM IND GRP SHENMU TIANYUAN CHEM IND

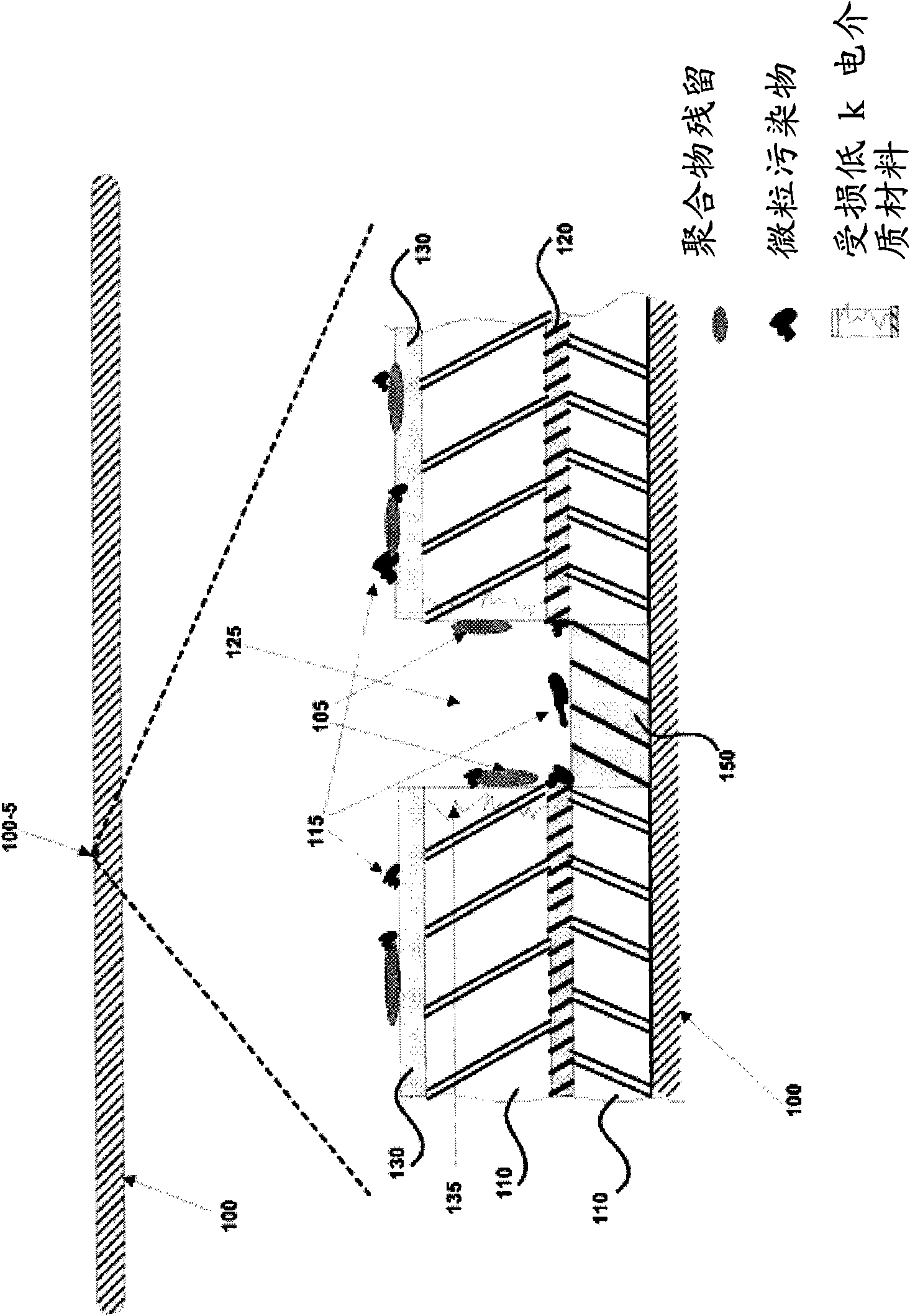

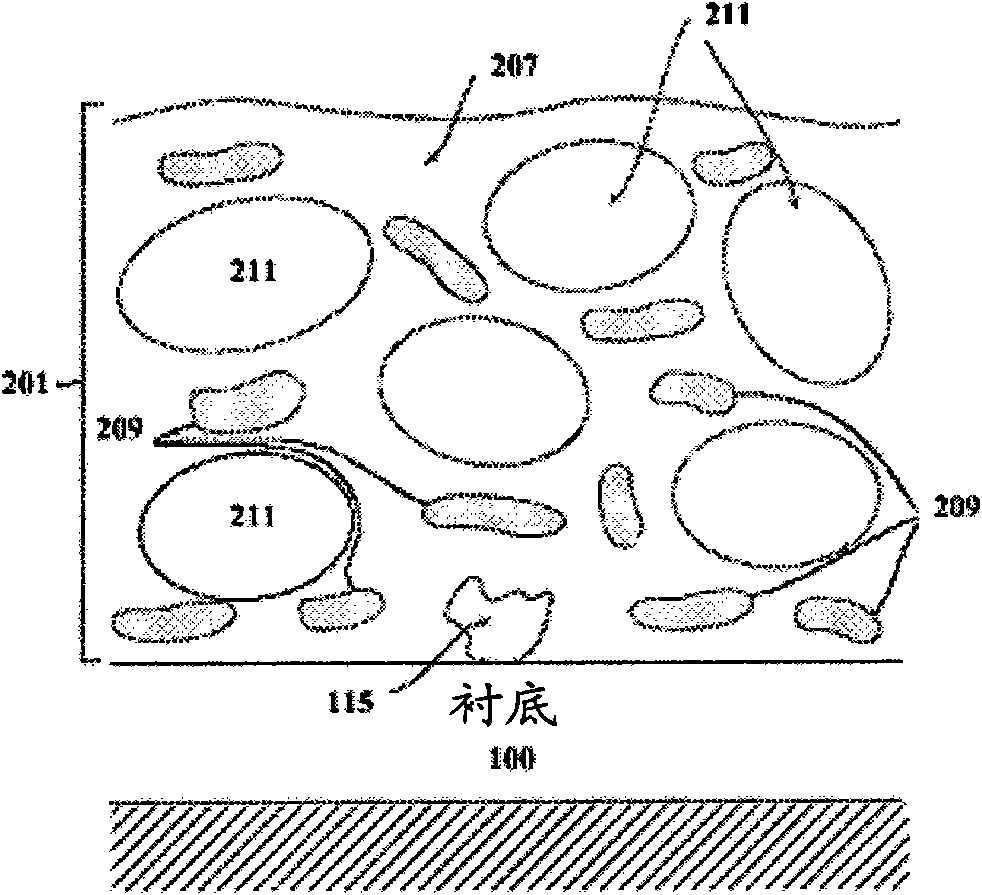

Method of dielectric film treatment

InactiveCN101971297AEasy to understandEasy to cleanSemiconductor/solid-state device manufacturingEmulsionChemical used

A method and system for cleaning a surface of a substrate after an etching operation includes determining a plurality of process parameters associated with the surface of the substrate. The process parameters define characteristics related to the surface of the substrate such as characteristics of the substrate surface to be cleaned, contaminants to be removed, features formed on the substrate and chemicals used in the fabrication operations. A plurality of application chemistries are identified based on the process parameters. The plurality of application chemistries includes a first application chemistry as an emulsion having a first immiscible liquid combined with a second immiscible liquid and solid particles distributed within the first immiscible liquid. The plurality of applicationchemistries including the first application chemistry are applied to the surface of the substrate such that the combined chemistries enhance the cleaning process by substantially removing the particulate and polymer residue contaminants from the surface of the substrate while preserving the characteristics of the features and of the low-k dielectric material through which the features are formed.

Owner:LAM RES CORP

Electrostatic separation device, process and slurry purification device for removing solid particles in catalytic cracking oil slurry

ActiveCN111454743BIncrease profitRemove helpRefining by electric/magnetic meansHydrocarbon oils treatmentElectrostatic separationPtru catalyst

The invention provides an electrostatic separation device for removing solid particles in catalytic cracking oil slurry, a process and an oil slurry purification device, and relates to the technical field of oil slurry purification treatment. It includes: uniformly distributing the catalytic cracking oil slurry in a plurality of electrostatic fields through a raw material distributor to perform purification treatment to remove solid particles in the catalytic cracking oil slurry. Using electrostatic field polarization, coalescence, adsorption, sedimentation, feed distribution and electrode plate combination application technology, etc., deep removal of catalyst solid ultrafine particles solves the problem that it is difficult to remove solid ultrafine particles by conventional separation methods, significantly. Improved solid particle removal efficiency. The electrostatic separation device provided by the invention has simple structure, convenient operation and is suitable for long-term operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fabric care tablet

InactiveCN110924175AAchieve removalImprove the effect of "renovation"Biochemical treatment with enzymes/microorganismsVegetal fibresAdhesiveActive agent

The invention discloses a fabric care tablet, and relates to the technical field of fabric care daily chemical products. Each unit of the tablet of the fabric care tablet includes, by mass percentage,300 to 2,400 U / g of cellulase; 5 to 20% of nonionic surfactant; 5 to 40% of hydrophilic silica; 5 to 10% of adhesive; and 1 to 10% of water. According to the scheme of the invention, through the compounding of various components, a synergistic effect is achieved, the stability of the cellulase can be improved, the activity of the cellulase in the washing process is released, the efficacy is exerted, and the storage and transportation of the product are facilitated. When in use, only the tablet needs to be put at one time, cotton fibers can be well removed for a single time to influence the apparent fluff and wool balls, the fabric color recovery is achieved, the effect of renovating the fabric is achieved, and meanwhile additional damage to the fabric is avoided.

Owner:GUANGZHOU LIBY

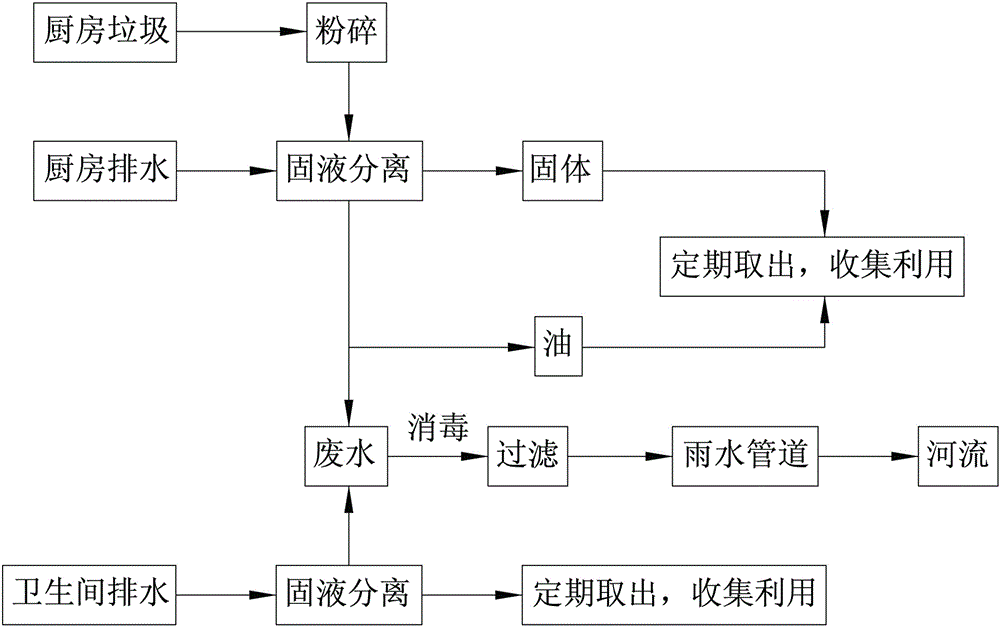

A kitchen and bathroom garbage and sewage treatment method and its integrated treatment device

ActiveCN103693817BAvoid new pollution problemsReduce dosageMultistage water/sewage treatmentWastewaterEngineering

The invention relates to a treatment method and device for kitchen wastes and wastewater. The treatment method comprises the following steps: (1) instantly filtering the kitchen wastewater and the smashed kitchen wastes to achieve solid-liquid separation; performing oil-water separation on the wastewater; instantly disinfecting toilet wastewater and filtering to achieve solid-liquid separation; (2) disinfecting the wastewater obtained after the oil-water separation of the kitchen wastewater, and further filtering the wastewater together with the wastewater obtained after the solid-liquid separation of the toilet wastewater. According to the integrated treatment device, a kitchen wastewater solid-liquid separation chamber and a toilet wastewater solid-liquid separation chamber are formed in a wastewater box, the kitchen wastewater solid-liquid separation chamber is connected with an oil storage chamber, and a solid-liquid separation filter box in the kitchen wastewater solid-liquid separation chamber is provided with a kitchen waste inlet. According to the treatment method and device, the discharge problem of household wastes and wastewater is solved from the source.

Owner:王凤蕊

Easy-to-remove ceramic core, and preparation method and application thereof

The invention relates to the technical field of ceramic cores, in particular to an easy-to-remove ceramic core, and a preparation method and application thereof. The preparation method of the easy-to-remove ceramic core comprises the following steps: mixing lanthanum oxide powder, calcium oxide powder and zirconium oxide powder to obtain a mixed material; carrying out dry pressing molding on the mixed material to obtain a biscuit; and sintering the biscuit to obtain the easy-to-remove ceramic core. According to the invention, lanthanum oxide is used as matrix powder, and calcium oxide and zirconium oxide react with lanthanum oxide in the sintering process, so it is guaranteed that the ceramic core is stored for a longer time, and removal of the ceramic core is facilitated. The prepared ceramic core is small in size change, easy to remove, high in refractoriness and good in thermal shock resistance.

Owner:SHANGHAI UNIV

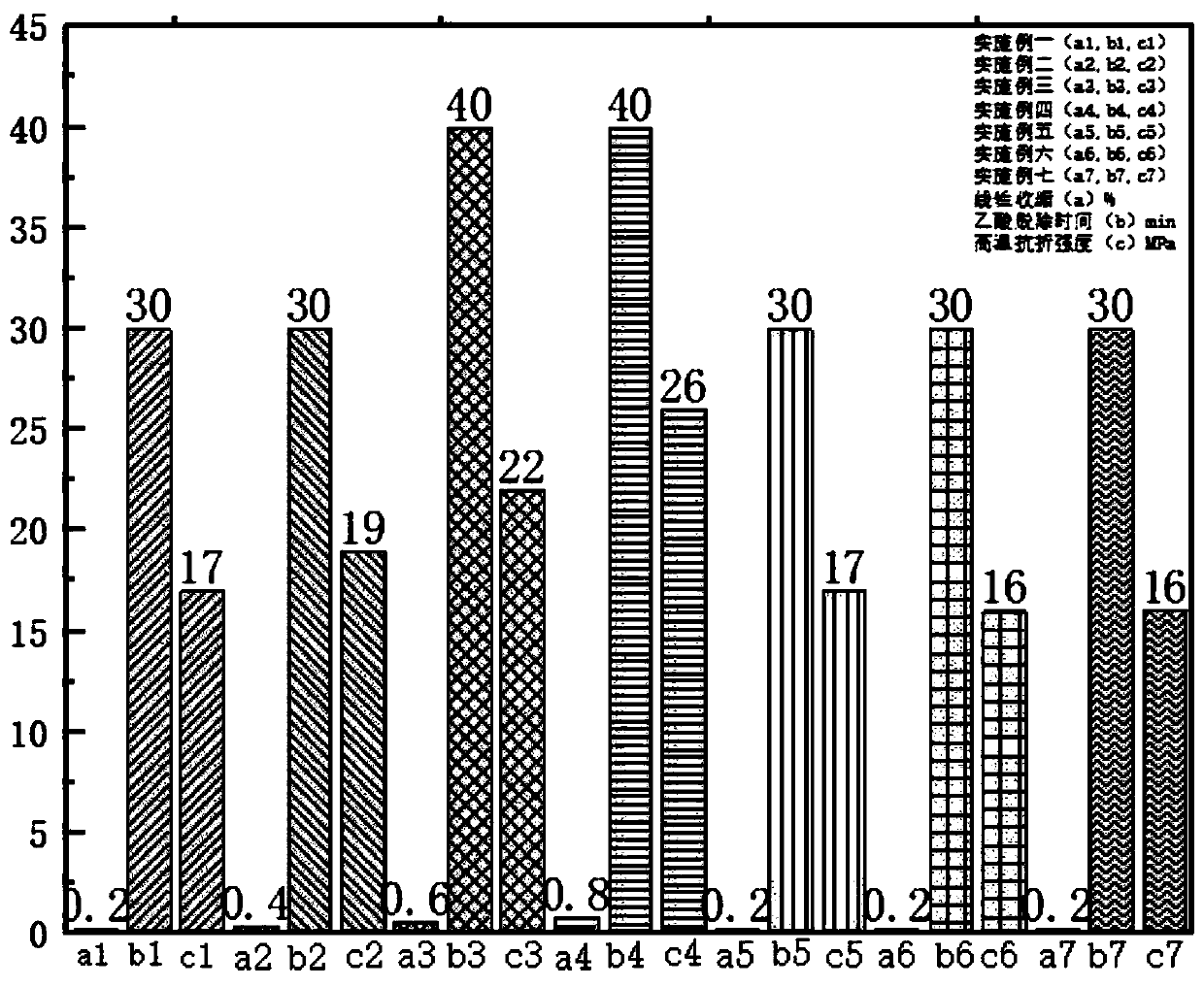

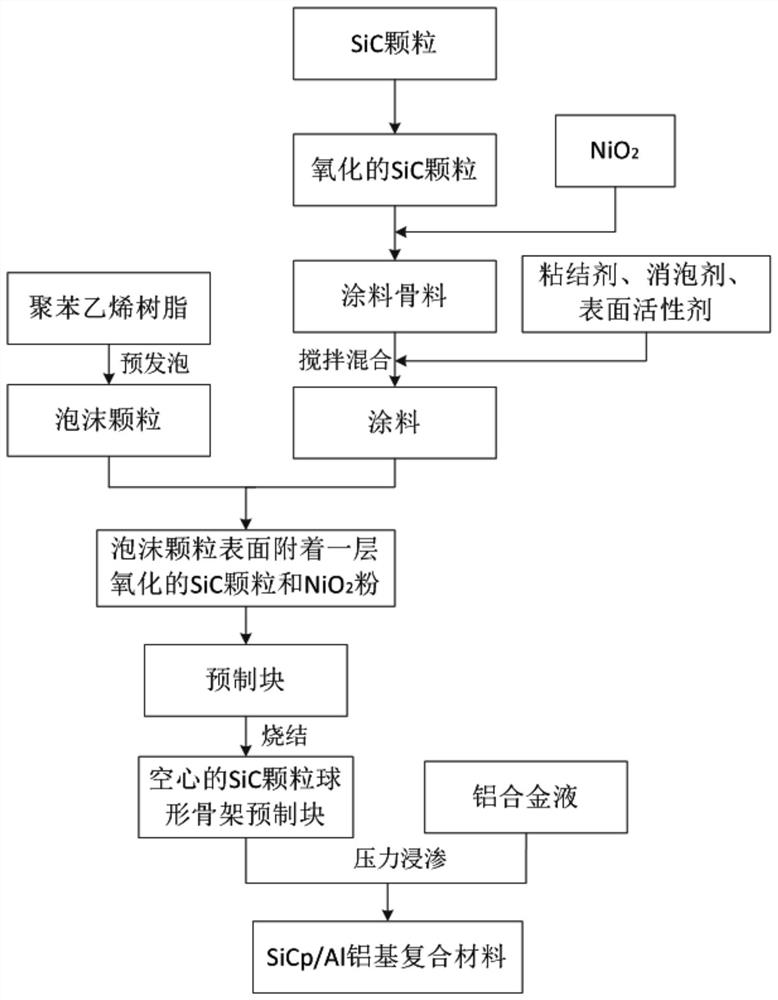

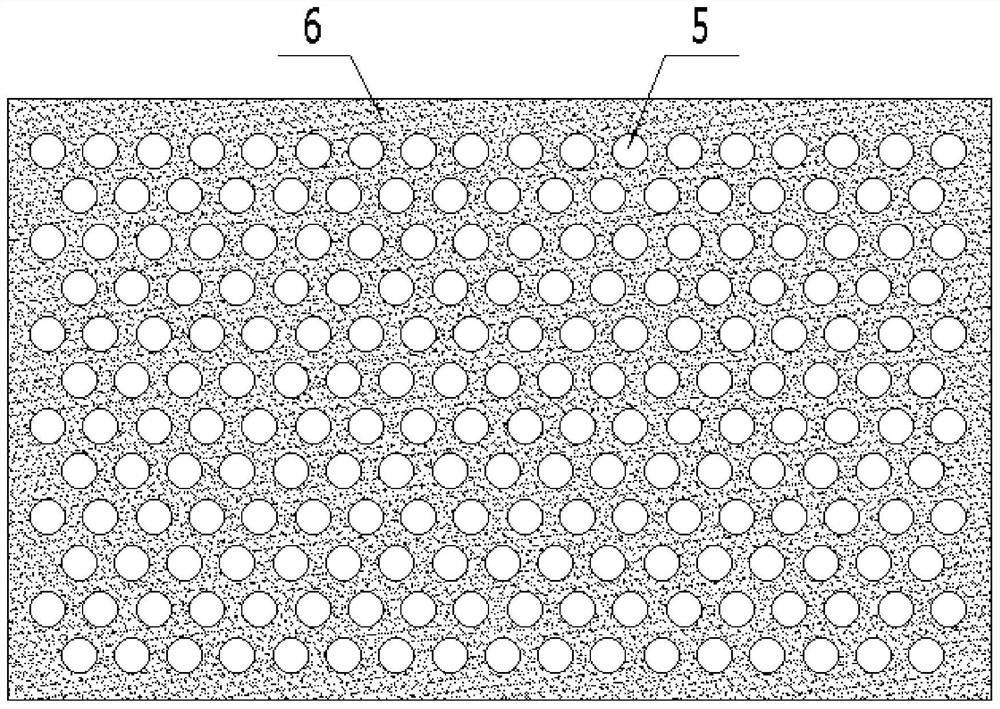

Constructible SiCp/Al matrix composite and preparation method thereof

ActiveCN111992694AHigh coating strengthControllable size distributionCeramicwareSilicic acidActive agent

The invention provides a constructible SiCp / Al matrix composite and a preparation method thereof. The preparation method comprises the following steps of S1, mixing oxidized SiC grains and NiO2 powder, and then mixing the mixed oxidized SiC grains and NiO2 powder with a bonder, an antifoaming agent and a surfactant evenly to form a coating; S2, evenly mixing the coating with foam grains, conducting filtering through a screen, charging the mixed materials into a mold cavity and pressing into a precast block; S3, drying and solidifying the precast block, and conducting sintering on the precast block at 700-900 DEG C for 2-3 h to form the precast block; and S4, pouring molten aluminum alloy into the mold cavity, and charging the preheated precast block on the molten aluminum alloy; or, charging the preheated precast block into the mold cavity and then pouring molten aluminum alloy; and conducting preparation through the pressure infiltration method to obtain the constructible SiCp / Al matrix composite. Through NiO2 and SiO2 oxidation layers, the wettability of SiC and aluminum alloy is greatly improved. Polystyrene pre-foamed grains and hydrolyzed ethyl orthosilicate can construct a voidage controllable SiC grain skeleton.

Owner:XIAN TECHNOLOGICAL UNIV

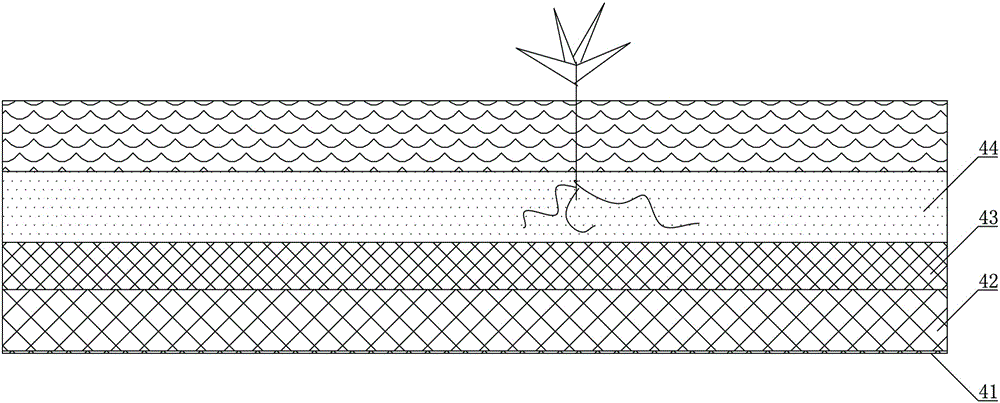

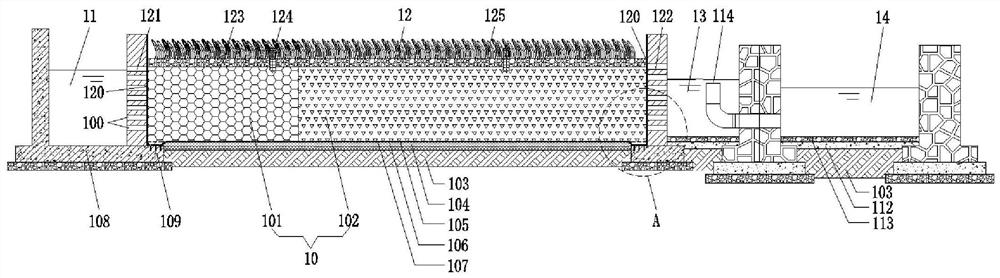

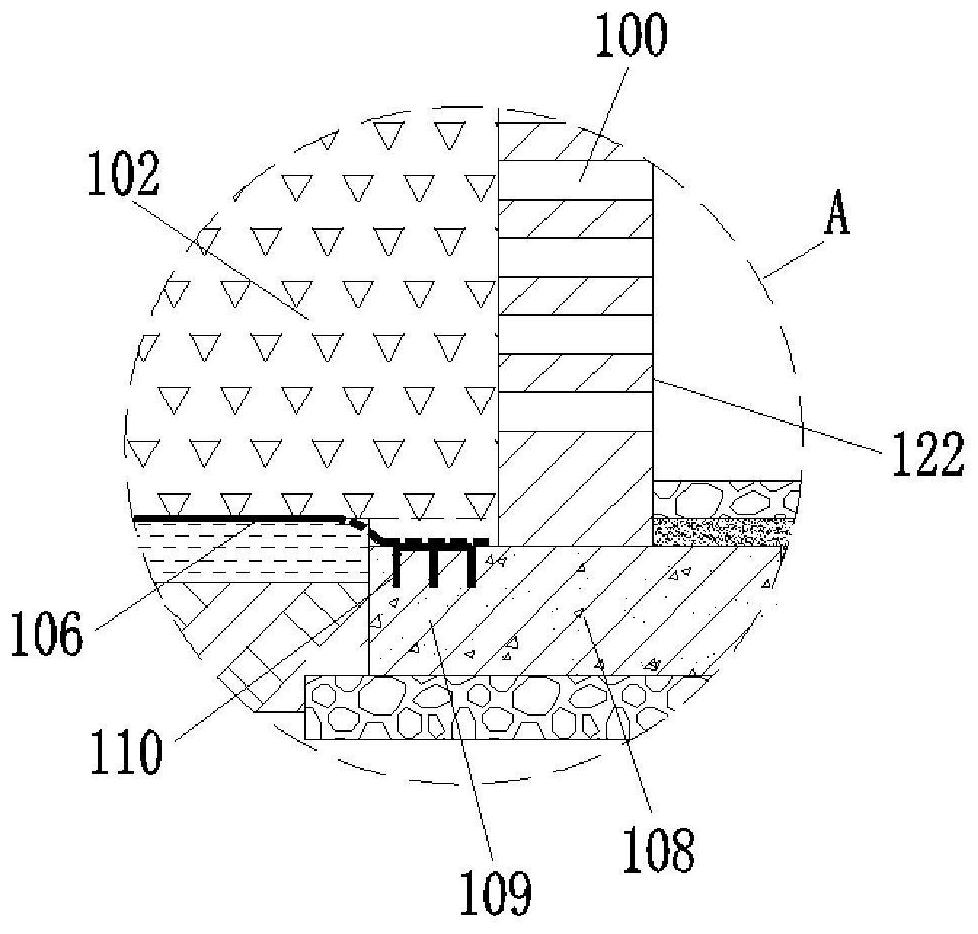

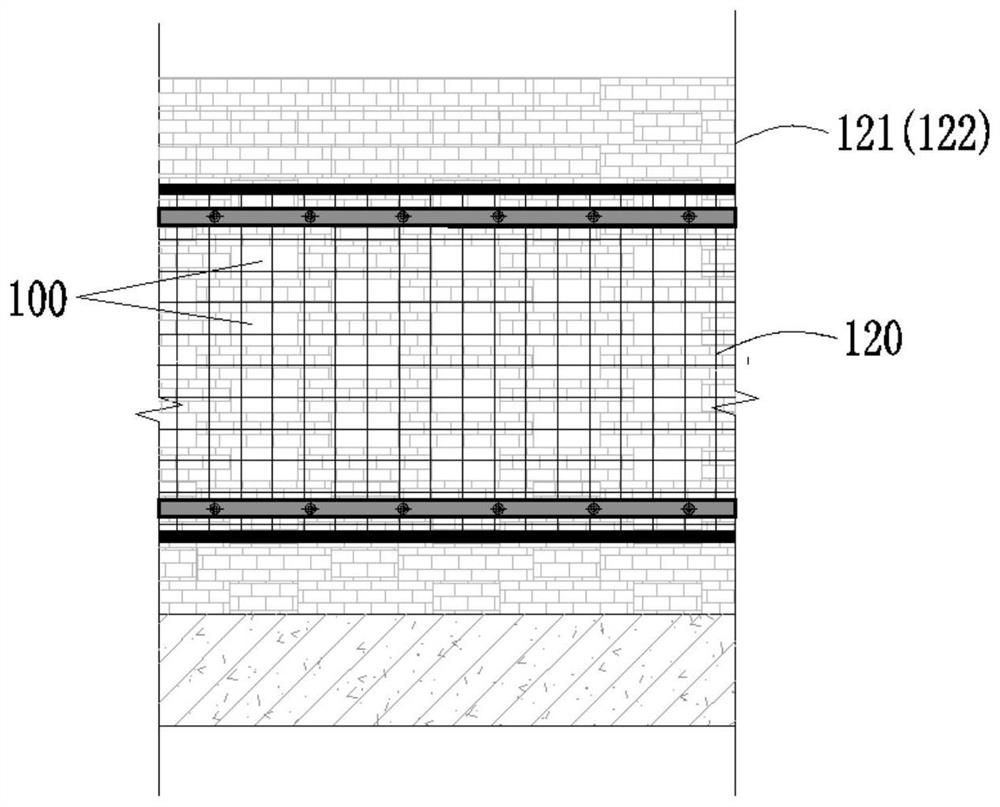

Subsurface coupled wetland for nitrogen and phosphorus removal

InactiveCN112851031APrevents the problem of large amounts of waterAchieve self-regulationWater contaminantsTreatment involving filtrationRiver routingStream flow

The invention discloses a subsurface coupled wetland for nitrogen and phosphorus removal. The subsurface coupled wetland comprises a water inlet channel, a wetland main body and a water outlet channel which are sequentially arranged along a water inlet direction, wherein the wetland main body comprises a water inlet distribution lattice wall, a water outlet distribution lattice wall and a filler area arranged between the water inlet distribution lattice wall and the water outlet distribution lattice wall, the filler area is filled with a phosphorus removal filter material, the water inlet distribution lattice wall is arranged at the joint of the water inlet channel and the wetland main body, the water outlet distribution lattice wall is arranged at the joint of the wetland main body and the water outlet channel, and the water inlet distribution lattice wall and the water outlet distribution lattice wall are respectively provided with a plurality of rows of water through holes. According to the invention, the subsurface coupled wetland is used for river channel water quality treatment, shows horizontal subsurface flow at low flow, has good pollutant removal capacity, ensures effluent quality, takes surface flow as a main part and subsurface flow as an auxiliary part at high flow, prevents suspended matters from entering a filter bed to cause blockage, and prolongs the service life of a wetland; and the water distribution lattice walls are respectively arranged at the water inlet end and the water outlet end of the wetland main body, so that self-regulation of flow is realized, surface flow / subsurface flow can be automatically regulated according to the water level, and manual control regulation is not needed.

Owner:HANGZHOU QINLIN ECOLOGICAL TECH CO LTD

Cutting and deburring dual-functional aluminum alloy cutting machine

PendingCN106862937AGood removal effectRemove helpOther manufacturing equipments/toolsElectric machineryStructural engineering

The invention relates to a cutting and deburring dual-functional aluminum alloy cutting machine which comprises a rack and a cutting saw blade; the aluminum alloy cutting machine further comprises a deburring wheel and a U-shaped installation part, wherein the cutting saw blade and the deburring wheel are movably connected with the U-shaped installation part; the cutting saw blade is in drive connection with a cutting motor; the deburring wheel is in drive connection with a deburring motor; the cutting motor and the deburring motor are opposite in the directions of rotation; the thickness of the deburring wheel is 1.2-1.5 times that of the saw blade; the deburring wheel is a grinding wheel; the U-shaped installation part is in rail connection with the rack; the U-shaped installation part is provided with a handle. The cutting and deburring dual-functional aluminum alloy cutting machine has the benefits as follows: when aluminum section is cut, the deburring operation is carried out, so that the cutting processing efficiency is fully improved.

Owner:江苏飞斯铝业有限公司

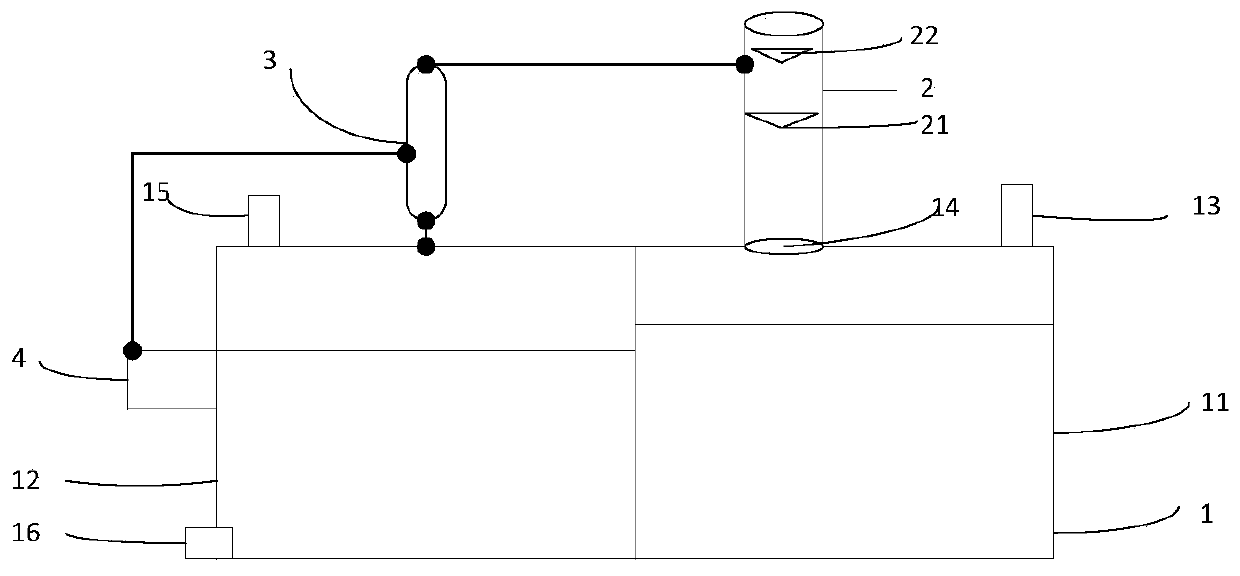

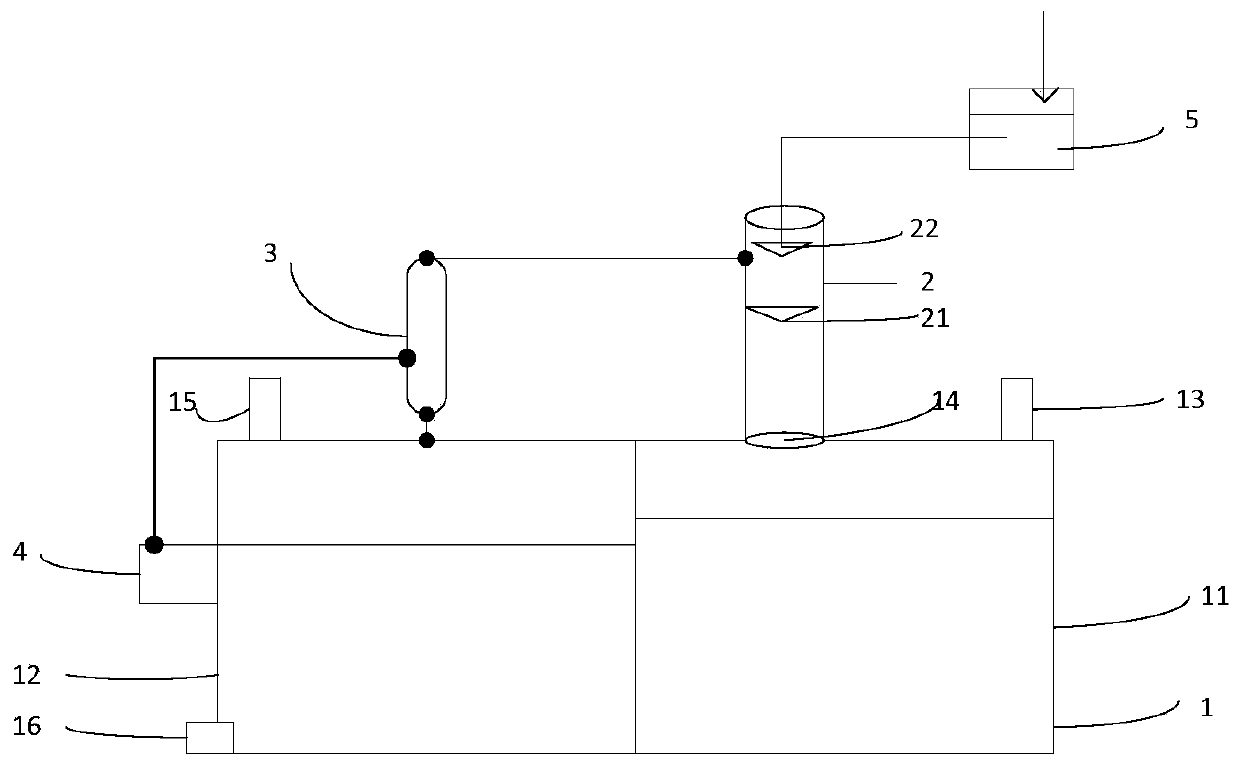

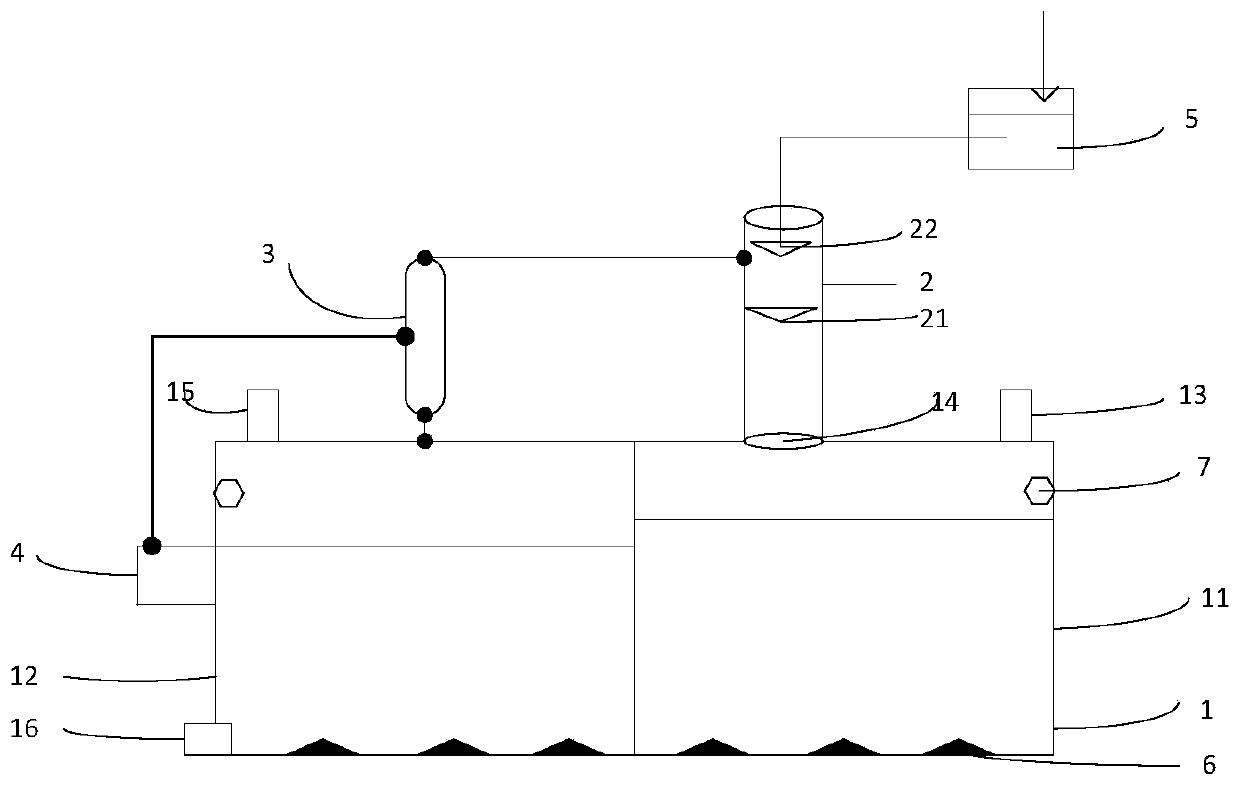

Device and method for removing suspended-material particles

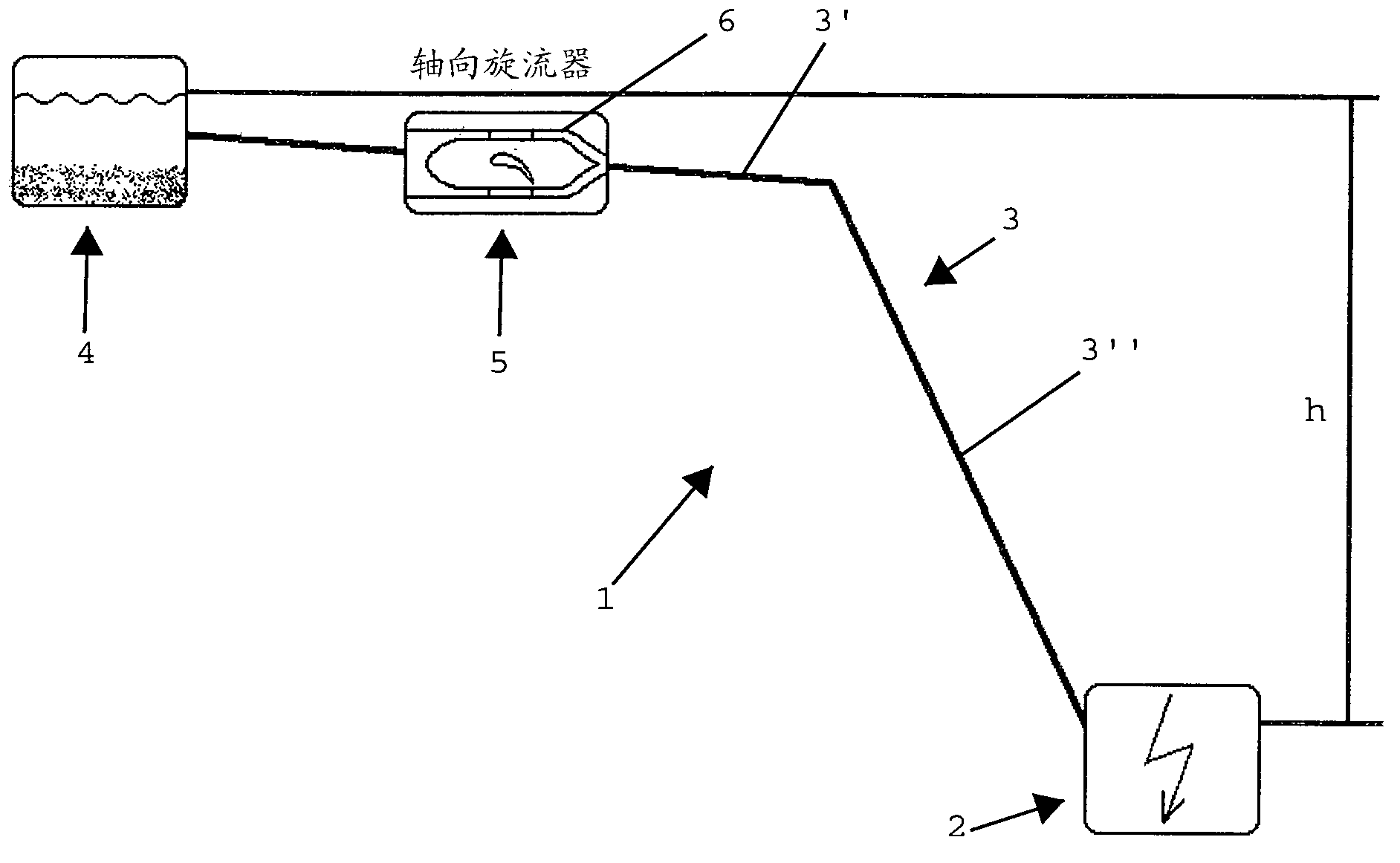

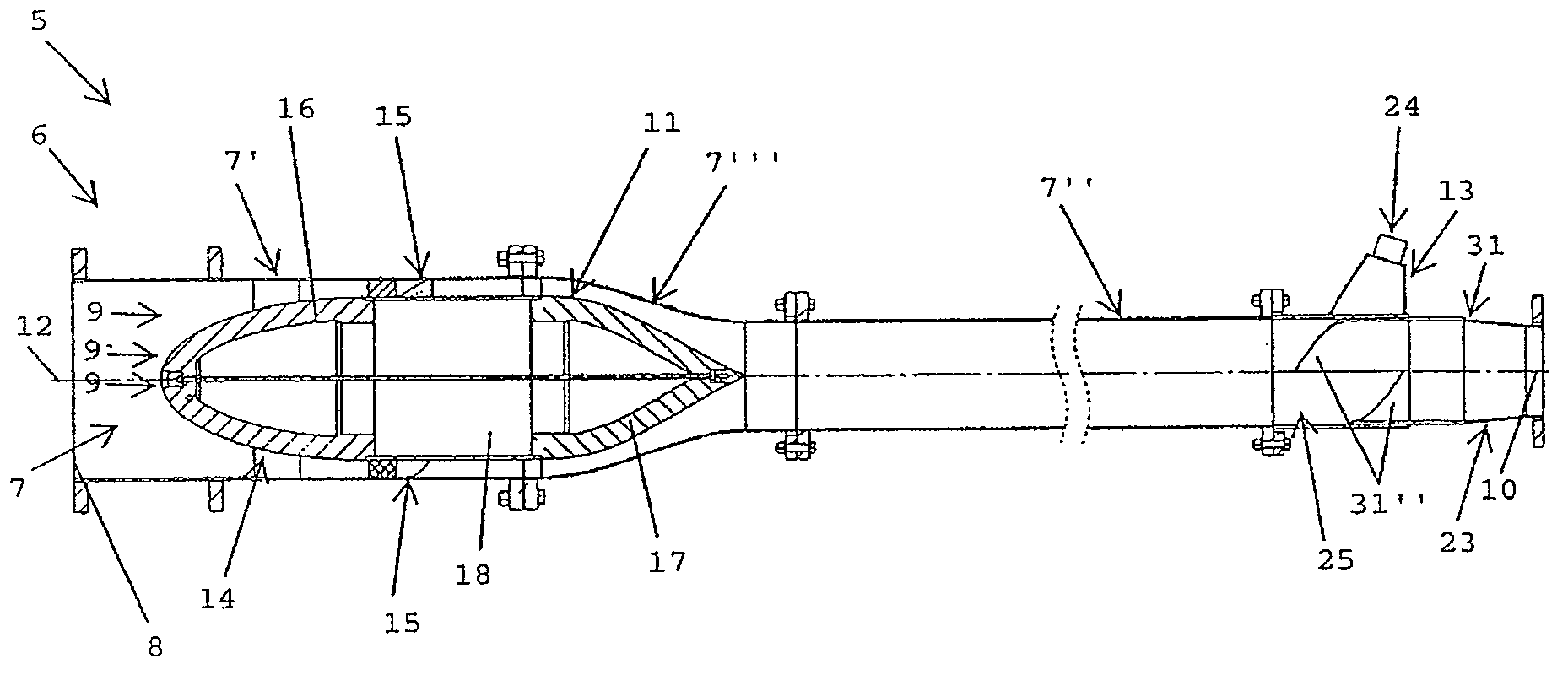

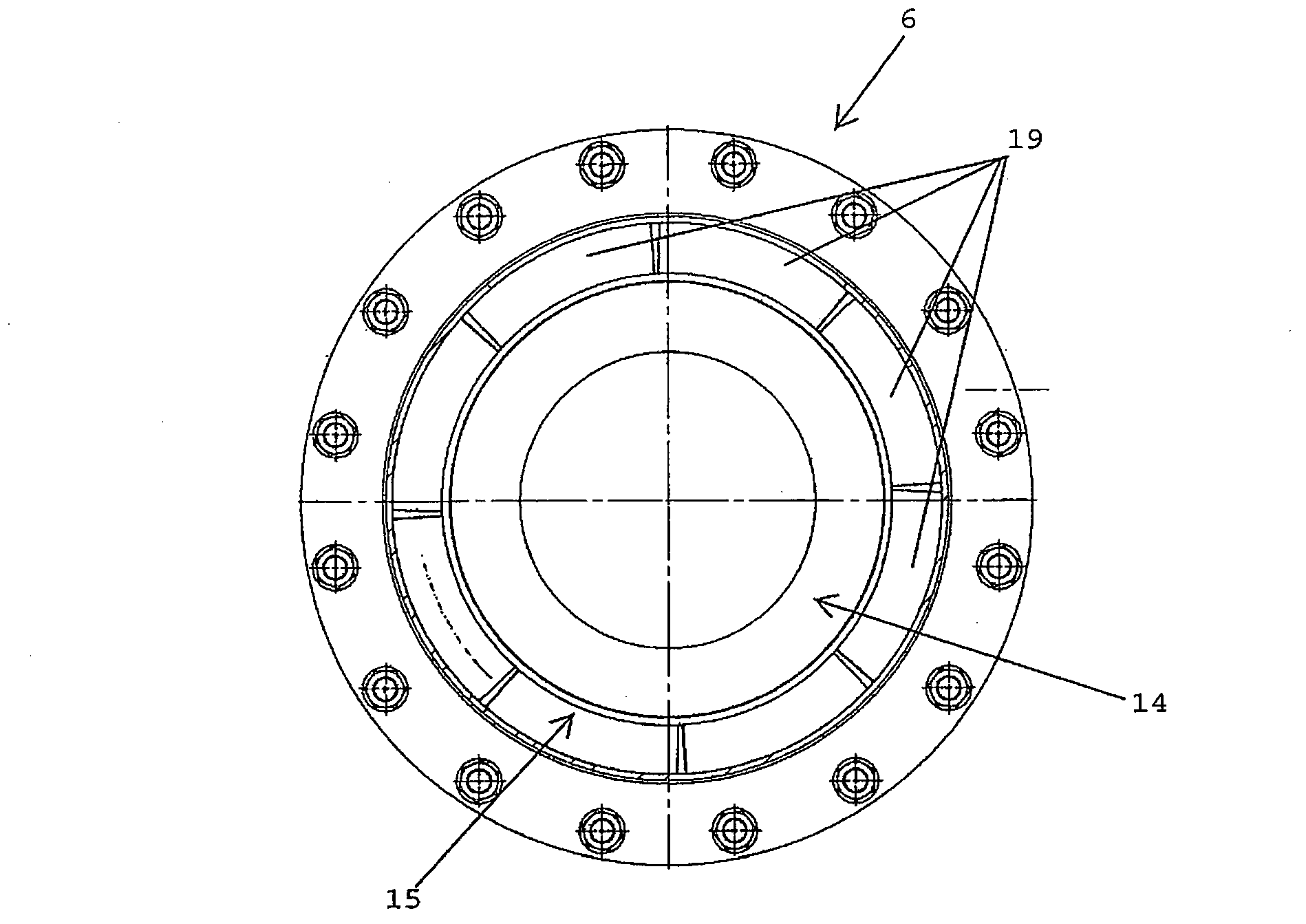

InactiveCN102762308AProcess loss is smallSmall pressure lossWater/sewage treatment by centrifugal separationEngine fuctionsWater flowEngineering

The invention relates to a device (5) and method for removing suspended-material particles, in particular fine and very fine particles, from a water flow containing suspended-material particles in a pressurized water line (3) of a hydroelectric power plant (2), wherein a tubular element (6) that forms a flow channel (7) is provided in the pressurized water line (3), wherein the flow channel (7) extends substantially in the axial direction of the pressurized water line (3), and a stationary swirl-generating device (11) is arranged in the flow channel (7) in order to generate a flow component of the water flow perpendicular to a main flow direction (9), and a separating device (13) for separating the suspended-material particles carried radially outward due to the centrifugal force effect is provided after the swirl-generating device (11) in the flow direction.

Owner:VIENNA UNIVERSITY OF TECHNOLOGY

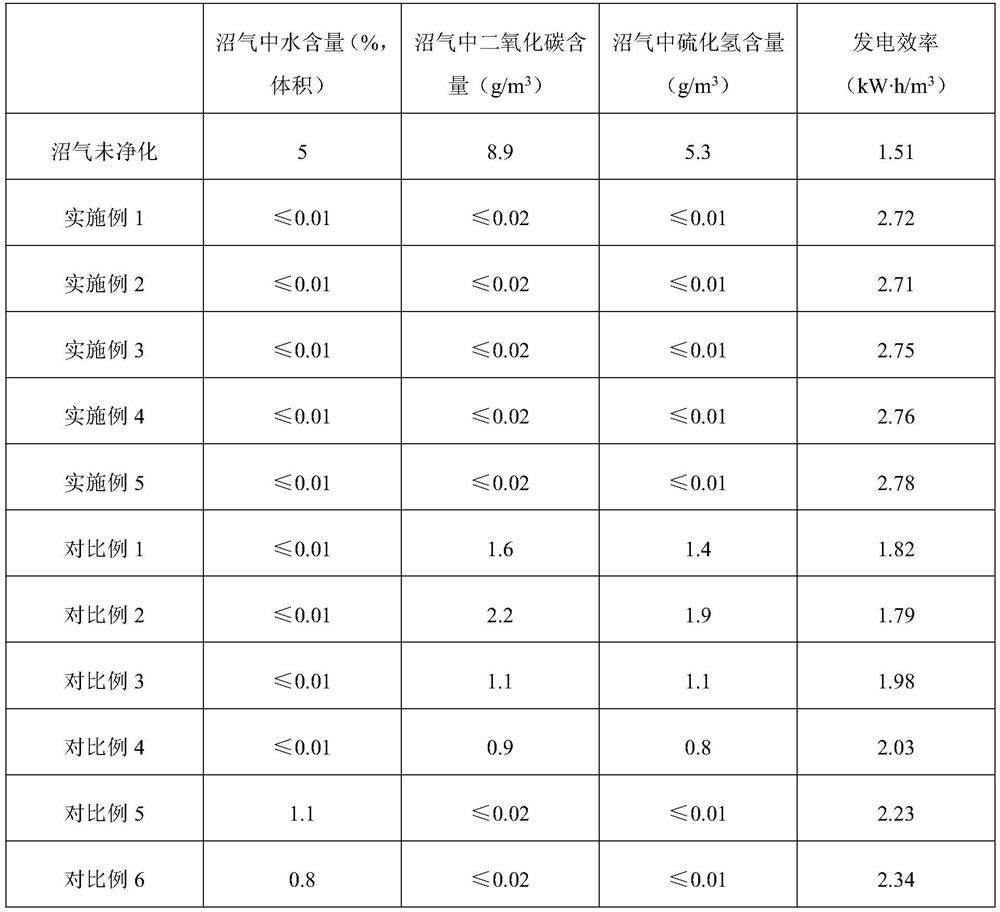

A method for biogas power generation

ActiveCN109868167BAchieve purificationReduce contentGaseous fuelsResidual carbonEnvironmental engineering

The invention provides a biogas power generation method. Biogas is purified before power generation, so that the quality of the biogas meets the requirements of power generation parameters so as to achieve higher power generation efficiency. Biogas first passes through a pretreatment pipeline filled with silica gel at a flow rate of 12-15m / s, then successively passes through a first pipeline filled with a first treatment agent, a second pipeline filled with a second treatment agent and a third pipeline filled with a third treatment agent, and finally passes through an end pipeline filled withsilica gel, and the purified biogas is led out. The pretreatment pipeline is used for drying and removing most of the moisture in biogas. The first pipeline is used for adsorbing and removing most carbon dioxide and a small part of hydrogen sulfide. The second pipeline is used for adsorbing and removing hydrogen sulfide and a small part of carbon dioxide. The third pipeline is used for adsorbing and removing residual carbon dioxide and hydrogen sulfide. The residual moisture is removed by adsorption through the end pipeline, and the purified biogas has low contents of water, hydrogen sulfide,carbon dioxide, etc, and has high power generation efficiency.

Owner:广东新科迪环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com