Tail gas treatment device

A tail gas treatment and nitrogen technology, which is applied in gas treatment, dispersed particle separation, membrane technology, etc., can solve the problems of backflow of tail gas, unstable negative pressure of epitaxial furnace, and blockage of tail gas treatment device, so as to reduce maintenance cost and extend maintenance cycle Long, avoid clogging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

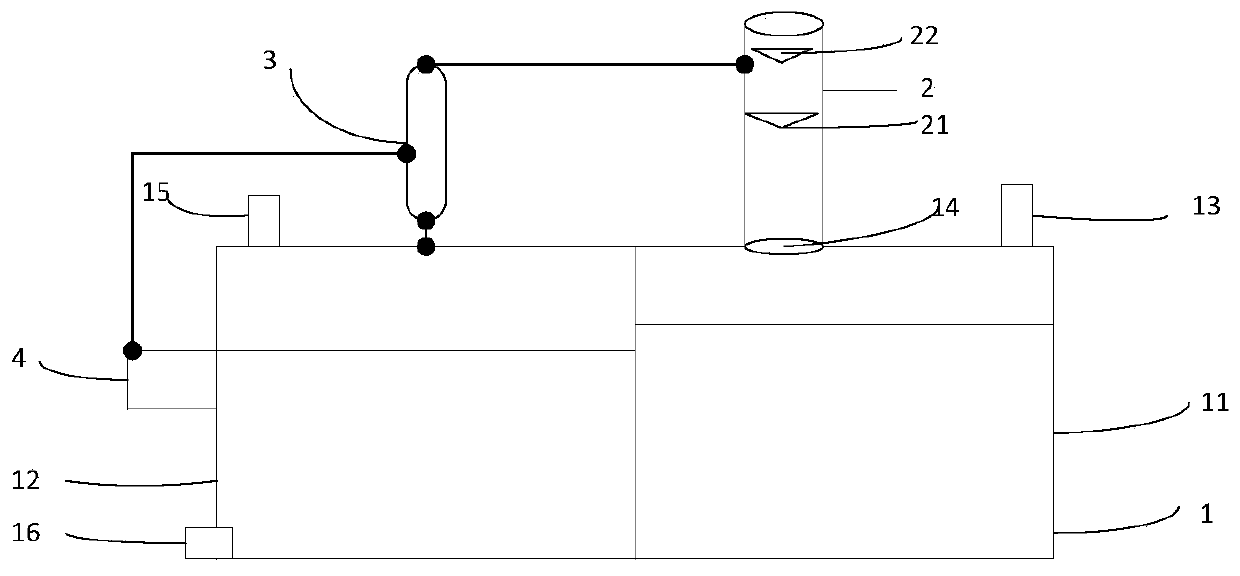

[0062] A tail gas treatment device, specifically as figure 1 shown, including:

[0063] A water tank (1), the water tank (1) is divided into a negative pressure chamber (11) and a normal pressure chamber (12), and water is stored in the negative pressure chamber (11) and the normal pressure chamber (12);

[0064] The negative pressure chamber (11) is provided with an air inlet (13) and a channel (14);

[0065] One spray tower (2), the top of described spray tower (2) is provided with water spray outlet (21) and lye spray outlet (22), the bottom of described spray tower (2) and described The passage (14) of the negative pressure chamber (11) is connected, and the passage is used to input gas into the spray tower, and the solid impurities in the spray tower are discharged into the negative pressure chamber;

[0066] The atmospheric chamber (12) is provided with an air outlet (15) at the top and a drain (16) at the bottom;

[0067] The normal pressure chamber (12) is connected...

Embodiment 2

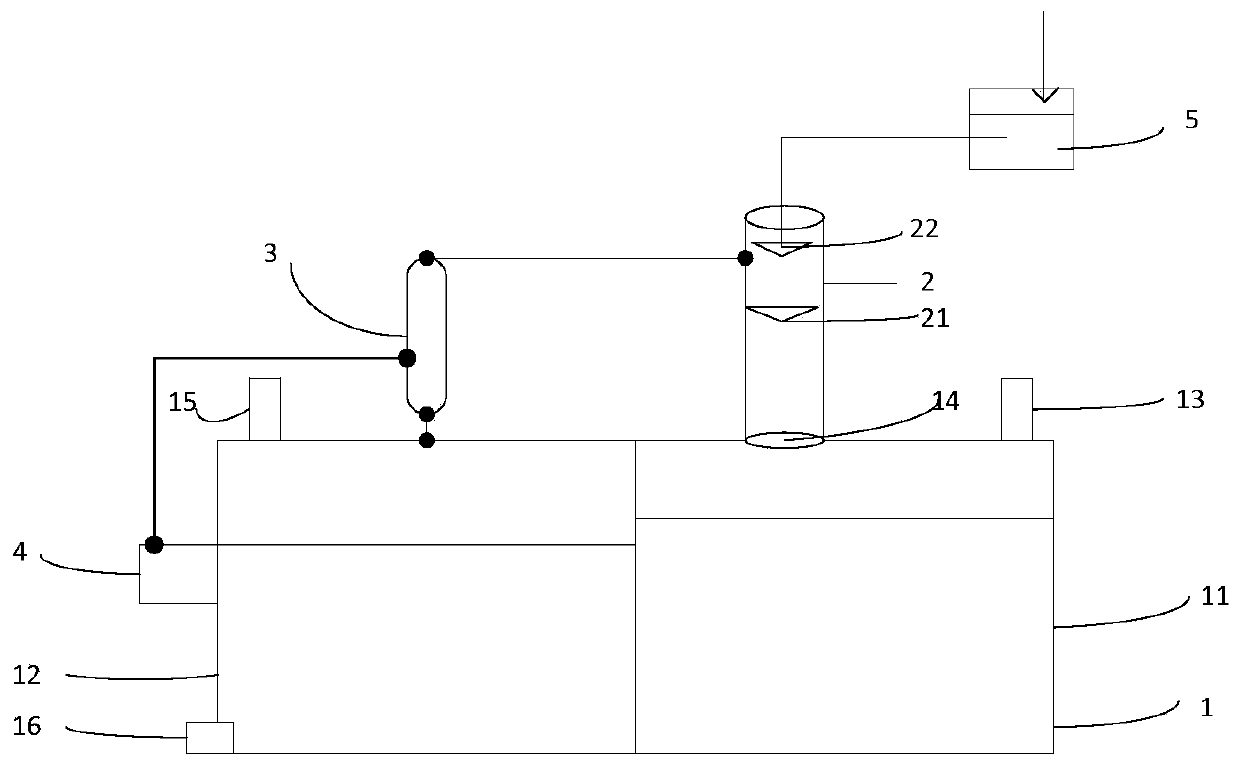

[0070] A tail gas treatment device, specifically as figure 2 shown, including:

[0071] A water tank (1), the water tank (1) is divided into a negative pressure chamber (11) and a normal pressure chamber (12), and water is stored in the negative pressure chamber (11) and the normal pressure chamber (12);

[0072] The negative pressure chamber (11) is provided with an air inlet (13) and a channel (14);

[0073] One spray tower (2), the top of described spray tower (2) is provided with water spray outlet (21) and lye spray outlet (22), the bottom of described spray tower (2) and described The passage (14) of the negative pressure chamber (11) is connected, and the passage is used to input gas into the spray tower, and the solid impurities in the spray tower are discharged into the negative pressure chamber;

[0074] The lye supply unit (5) is connected with the lye spray port (22) at the top of the spray tower;

[0075] The lye supply unit includes an lye storage unit and a ...

Embodiment 3

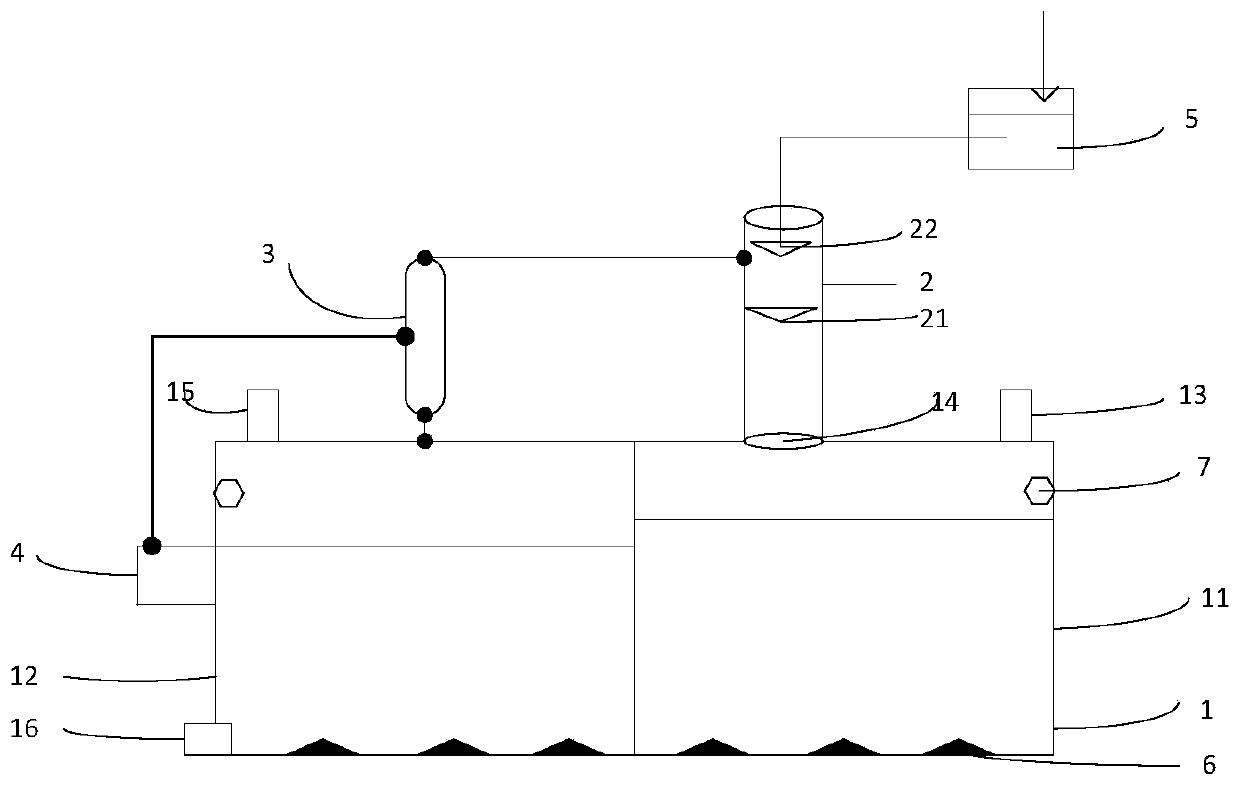

[0080] A tail gas treatment device, specifically as image 3 shown, including:

[0081] A water tank (1), the water tank (1) is divided into a negative pressure chamber (11) and a normal pressure chamber (12), and water is stored in the negative pressure chamber (11) and the normal pressure chamber (12);

[0082] The negative pressure chamber (11) is provided with an air inlet (13) and a channel (14);

[0083] One spray tower (2), the top of described spray tower (2) is provided with water spray outlet (21) and lye spray outlet (22), the bottom of described spray tower (2) and described The passage (14) of the negative pressure chamber (11) is connected, and the passage is used to input gas into the spray tower, and the solid impurities in the spray tower are discharged into the negative pressure chamber;

[0084] The atmospheric chamber (12) is provided with an air outlet (15) at the top and a drain (16) at the bottom;

[0085] The normal pressure chamber (12) is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com