Concrete regeneration process and concrete formula

A concrete regeneration and concrete technology, which is applied in the field of concrete production, can solve the problems affecting the structural strength of recycled concrete, the complex composition of waste concrete, and the singleness of aggregate in recycled concrete.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

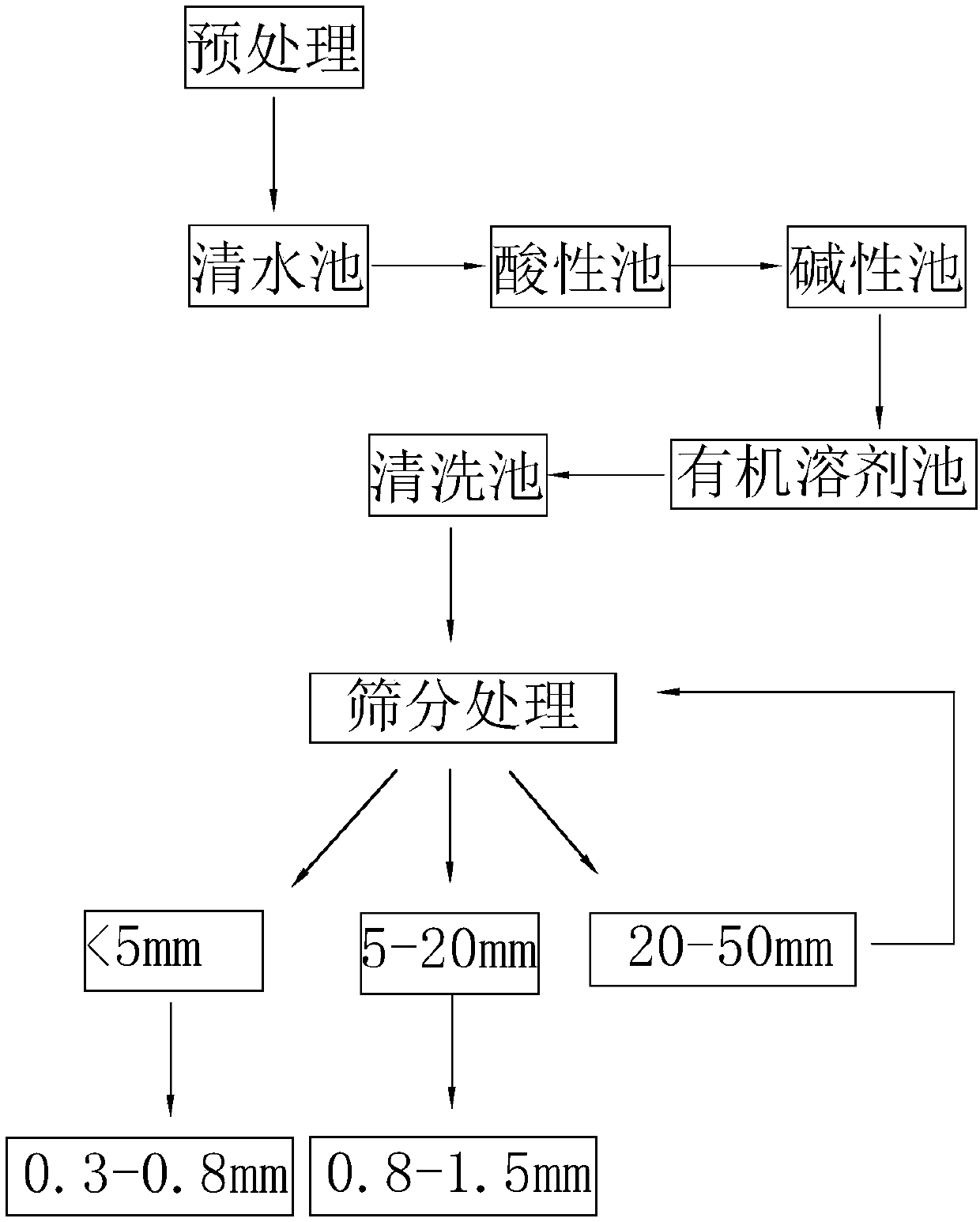

[0039] Such as figure 1 As shown, the waste concrete is hammered to make it broken into blocks, the diameter of the concrete block is less than 50mm, the steel bars in the concrete are stripped and removed, and the damaged concrete blocks are collected; the concrete blocks are put into the clear water pool Stir and wash to remove the impurities floating above the clear water pool, remove the concrete blocks that have sunk into the bottom of the clear water pool and put them in the sun to dry until there is no obvious water stain on the surface; put the dried concrete into the acid pool for further cleaning Wash for 5 minutes, and place a sufficient amount of acetic acid aqueous solution in the acidic pool; then remove the concrete block soaked in the acidic pool and put it into the alkaline pool for 10 minutes, where acetic acid and sodium acetate are placed; then Take out the concrete block soaked from the alkaline pool and put it into the organic solvent pool for filtration ...

Embodiment 2

[0041] Such as figure 1 As shown, the waste concrete is hammered to make it broken into blocks, the diameter of the concrete block is less than 50mm, the steel bars in the concrete are stripped and removed, and the damaged concrete blocks are collected; the concrete blocks are put into the clear water tank for Stir and wash, remove the impurities floating above the clear water pool, remove the concrete blocks that have sunk into the bottom of the clear water pool, and put them in the sun to dry until there is no obvious water stain on the surface; put the dried concrete into the acid pool for washing After washing for 10 minutes, a sufficient amount of acetic acid aqueous solution is placed in the acidic pool; after that, the concrete blocks soaked in the acidic pool are taken out and put into the alkaline pool for 15 minutes, where acetic acid and sodium acetate are placed; The concrete blocks soaked in the alkaline pool are taken out and put into the organic solvent pool for...

Embodiment 3

[0043] Such as figure 1 As shown, the waste concrete is hammered to make it broken into blocks, the diameter of the concrete block is less than 50mm, the steel bars in the concrete are stripped and removed, and the damaged concrete blocks are collected; the concrete blocks are put into the clear water tank for Stir and wash, remove the impurities floating above the clear water pool, remove the concrete blocks that have sunk into the bottom of the clear water pool, and put them in the sun to dry until there is no obvious water stain on the surface; put the dried concrete into the acid pool for washing Wash for 8 minutes, and there is a sufficient amount of acetic acid aqueous solution in the acidic pool; then remove the concrete block soaked in the acidic pool and put it into the alkaline pool for 13 minutes, where acetic acid and sodium acetate are placed; Take out the concrete block soaked in the alkaline pool and put it into the organic solvent pool for filtration and washin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com