Polymer material small-sized humidifying-dehumidifying desalination apparatus and manufacturing method

A technology of polymer materials and random packing, applied in the field of miniaturized humidification-dehumidification and desalination devices of polymer materials, can solve the problems of complex structure, difficulty in miniaturization, high manufacturing cost, etc., and achieve improved space allocation and wide application prospects , Promote droplet condensation of water vapor and enhance heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

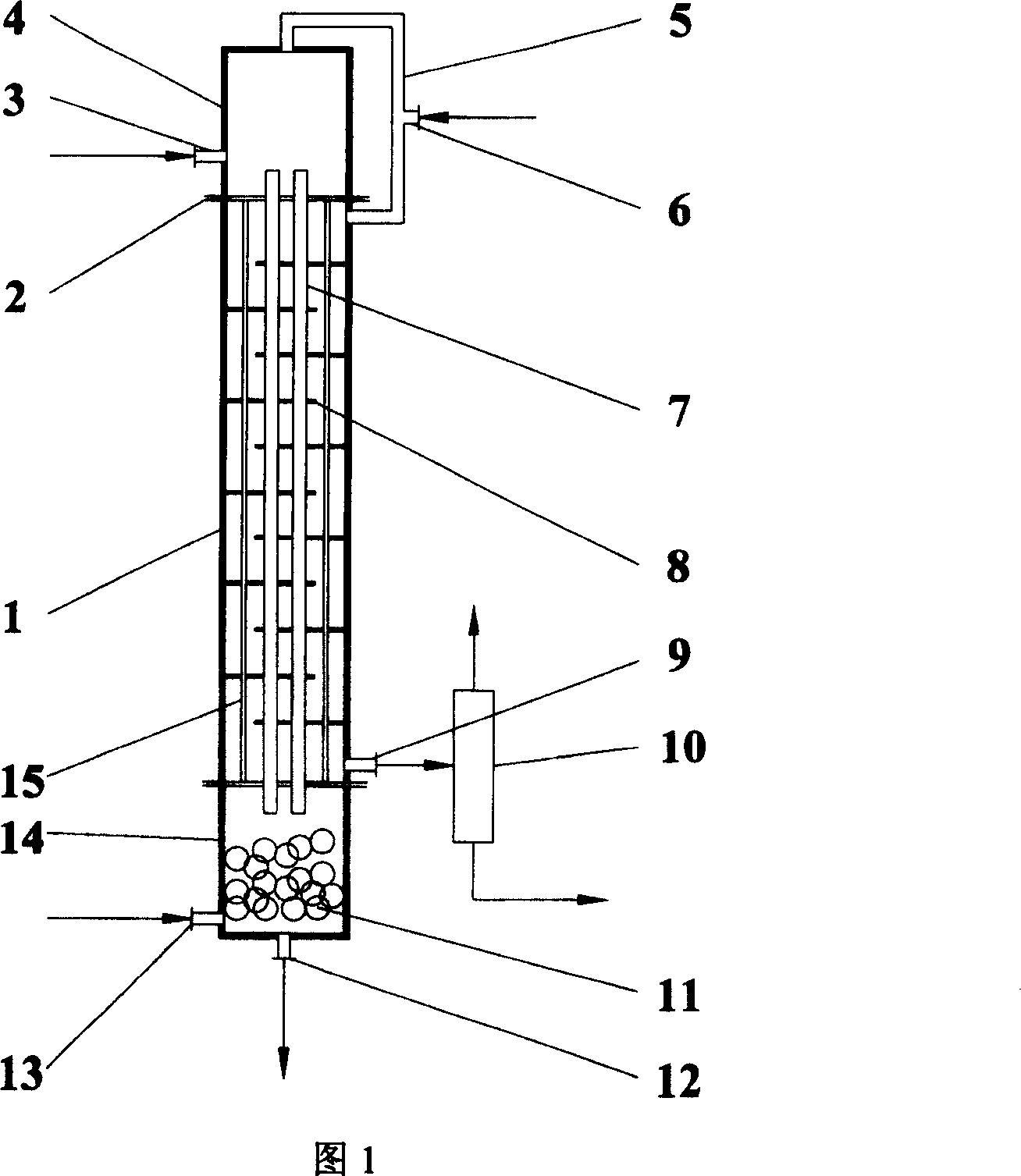

[0028] The present invention is further described in conjunction with accompanying drawing:

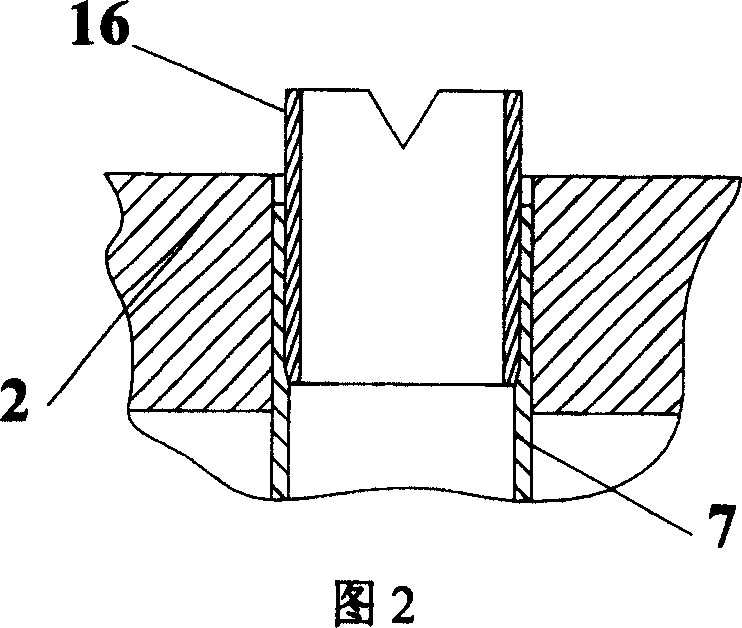

[0029] Mix 90% polypropylene, 5% polyphenylene ether and 5% graphite. After melting, use a spinneret composed of two concentric rings with gaps and textured inner ring surface to melt the molten material. Extruded and stretched to form a heat transfer tube 7 with a textured inner wall and a smooth outer wall, the average inner diameter of the heat transfer tube 7 is 3.5 mm, and the wall thickness is 30 μm. Concentration is that the ozone gas of 15mg / L is passed in the heat transfer tube 7, and processing time is 30 minutes. The treated inner wall surface of the heat transfer tube 7 has a certain degree of hydrophilicity and roughness, while the outer wall surface is a hydrophobic and smooth surface. The steam of the gas produces droplet condensation on the outer wall to enhance heat transfer.

[0030] Drill 43 tube holes with an inner diameter of 4.0mm on two polypropylene tube shee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com