High-strength thin-wall gray iron casting and preparation method thereof

A high-strength, gray iron technology, applied in casting molding equipment, casting molds, casting mold components, etc., can solve the problems of loss of alloying effect, high cost, casting pores, etc., and achieves low production cost, simple preparation method, The effect of high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

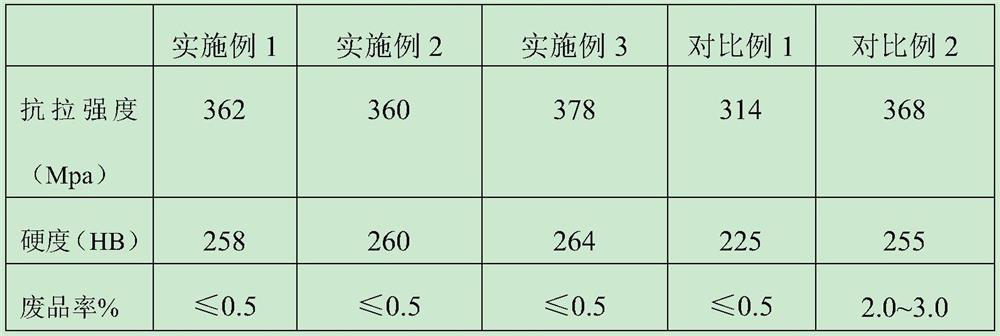

Examples

Embodiment 1

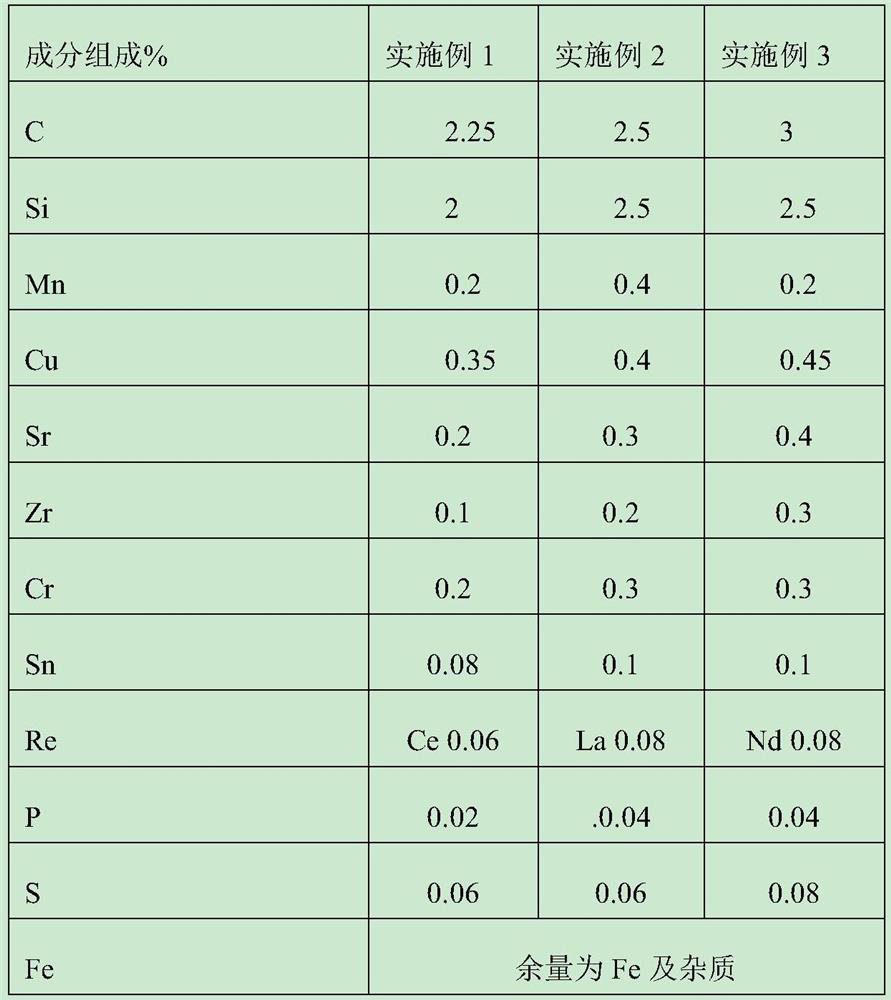

[0026] Weigh concrete raw material by table 1, all the other steps preparation steps are as follows:

[0027] (1) Melting: put each raw material into an intermediate frequency melting furnace for melting, the melting temperature is 1530°C, measure the content of each element, and adjust the content of each element to meet the formula requirements to obtain molten iron;

[0028] (2) High-temperature refining: adjust the temperature of molten iron to 1580°C, and remove slag after holding for 115 minutes;

[0029] (3) Initial inoculation: the temperature is controlled at 1540° C., adding an initial inoculant of 0.5% molten iron weight into step (2), performing floating silicon inoculation treatment, removing scum, and obtaining initial inoculated molten iron;

[0030] (4) carburizing: temperature is controlled at 1550 ℃, and the carburizing agent of 0.8% initial inoculation liquid iron weight is added in the step (3), obtains carburizing molten iron;

[0031] (5) re-inoculation:...

Embodiment 2

[0037] Weigh concrete raw material by table 1, all the other steps preparation steps are as follows:

[0038] (1) Melting: put each raw material into an intermediate frequency melting furnace for melting, the melting temperature is 1550°C, measure the content of each element, and adjust the content of each element to meet the formula requirements to obtain molten iron;

[0039] (2) High-temperature refining: adjust the temperature of molten iron to 1600°C, and remove slag after holding for 10 minutes;

[0040] (3) Initial inoculation: the temperature is controlled at 1550° C., adding an initial inoculant of 0.3% molten iron weight into step (2), performing floating silicon inoculation treatment, removing scum, and obtaining initial inoculated molten iron;

[0041] (4) Carburizing: temperature is controlled at 1560 DEG C, and the carburizing agent of 0.5% initial inoculation molten iron weight is added in the step (3), obtains carburizing molten iron;

[0042] (5) re-inoculati...

Embodiment 3

[0048] Weigh concrete raw material by table 1, all the other steps preparation steps are as follows:

[0049] (1) Melting: put each raw material into an intermediate frequency melting furnace for melting, the melting temperature is 1550°C, measure the content of each element, and adjust the content of each element to meet the formula requirements to obtain molten iron;

[0050] (2) High-temperature refining: adjust the temperature of molten iron to 1600°C, and remove slag after holding for 15 minutes;

[0051](3) Initial inoculation: the temperature is controlled at 1550° C., adding an initial inoculant of 0.5% molten iron weight into step (2), performing floating silicon inoculation treatment, removing scum, and obtaining initial inoculated molten iron;

[0052] (4) Carburizing: the temperature is controlled at 1560° C., adding a recarburizing agent of 0.8% initial inoculated molten iron weight into step (3) to obtain carburizing molten iron;

[0053] (5) re-inoculation: the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com