Aero-engine formed by 3D printing

An aero-engine and 3D printing technology, which is applied in the direction of engine components, engine cooling, machine/engine, etc., can solve problems such as inability to achieve heat dissipation, simple structure, and heavy weight of aero-engines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

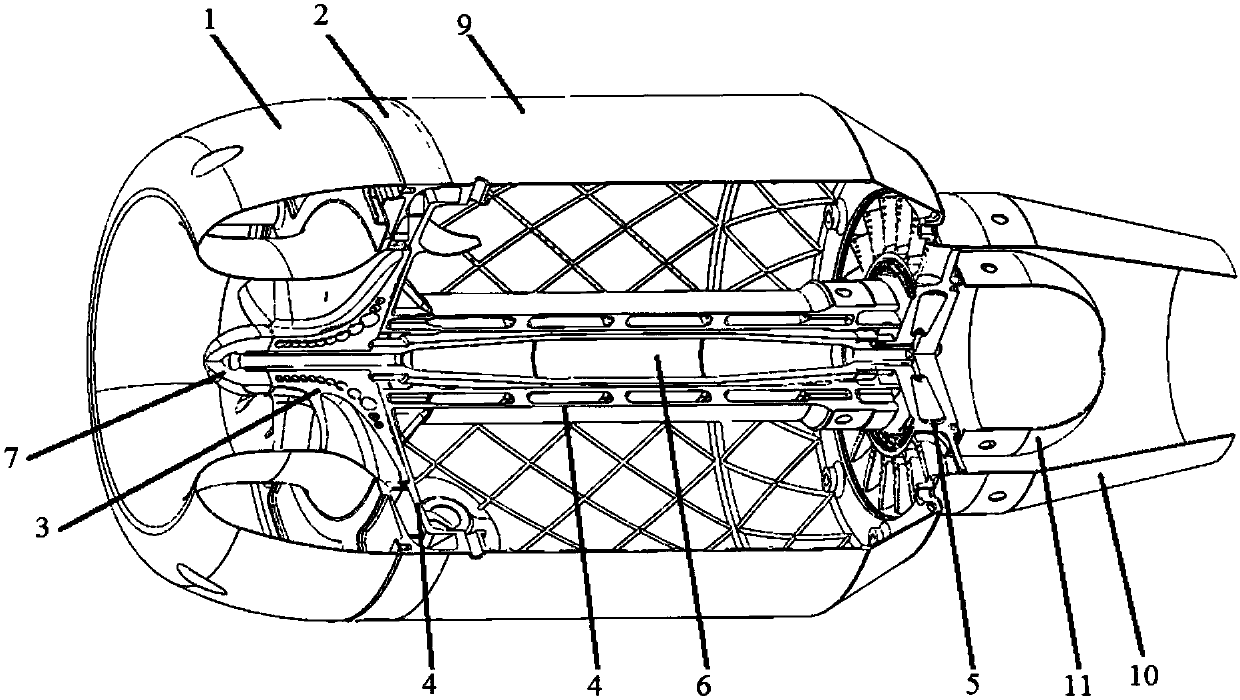

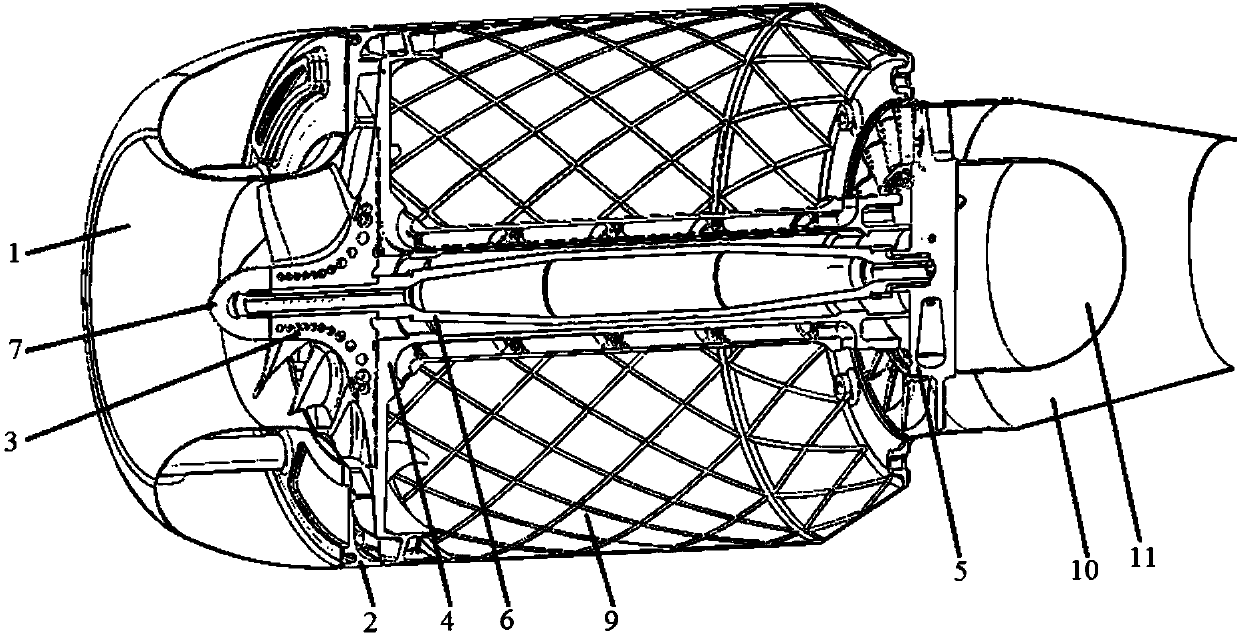

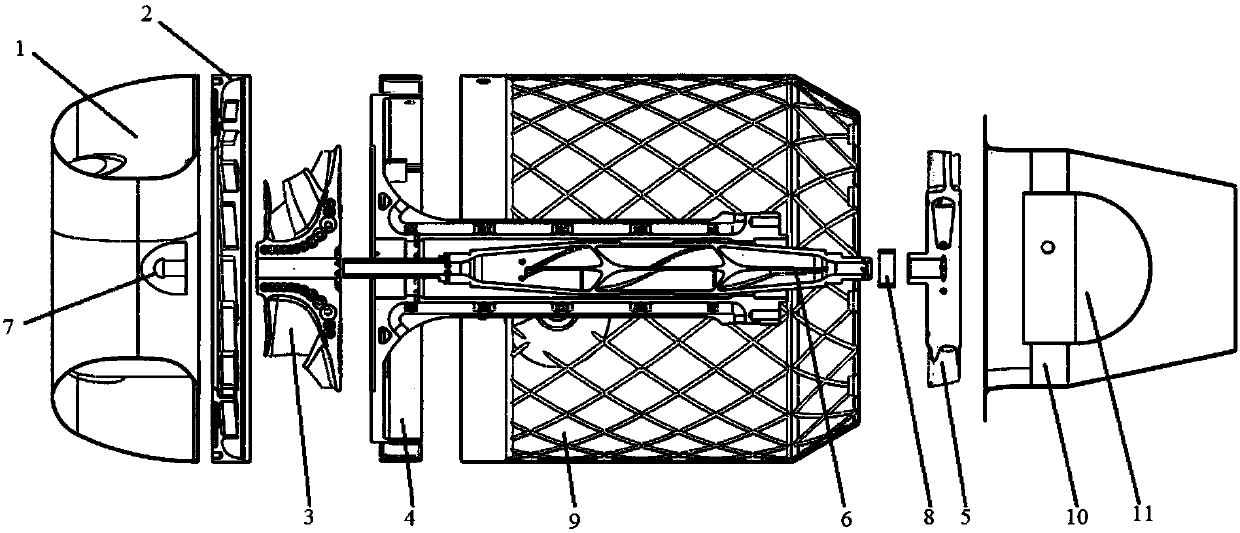

[0048] According to a preferred embodiment of the present invention, the compressor housing 1 has a height of 25-65 mm, preferably 30-60 mm, more preferably 35-55 mm.

[0049] According to a preferred embodiment of the present invention, the wall thickness of the compressor housing 1 is 0.1-0.5 mm, preferably 0.2-0.4 mm.

[0050] Wherein, the compressor casing 1 of the present invention is preferably made by 3D printing, so that a thin-walled compressor casing can be obtained, and the compressor casing 1 can be given a lighter weight.

[0051] In the present invention, in the compressor housing 1 , the junction of the annular outer surface and the annular inner surface is defined as the upper end of the compressor housing, and the bottom surface is defined as the lower end of the compressor housing. The "sector" in the "fan-shaped hole" refers to a part of the circular ring, that is, a part of the circular ring, such as Figure 7 Shown in 112.

[0052] According to a preferr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com