Easy-to-remove ceramic core, and preparation method and application thereof

A ceramic core and removal technology, applied in cores, casting molding equipment, casting molds, etc., can solve problems such as poor performance of ceramic substrates, and achieve the effects of small dimensional changes, improved thermal shock resistance, and low prices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

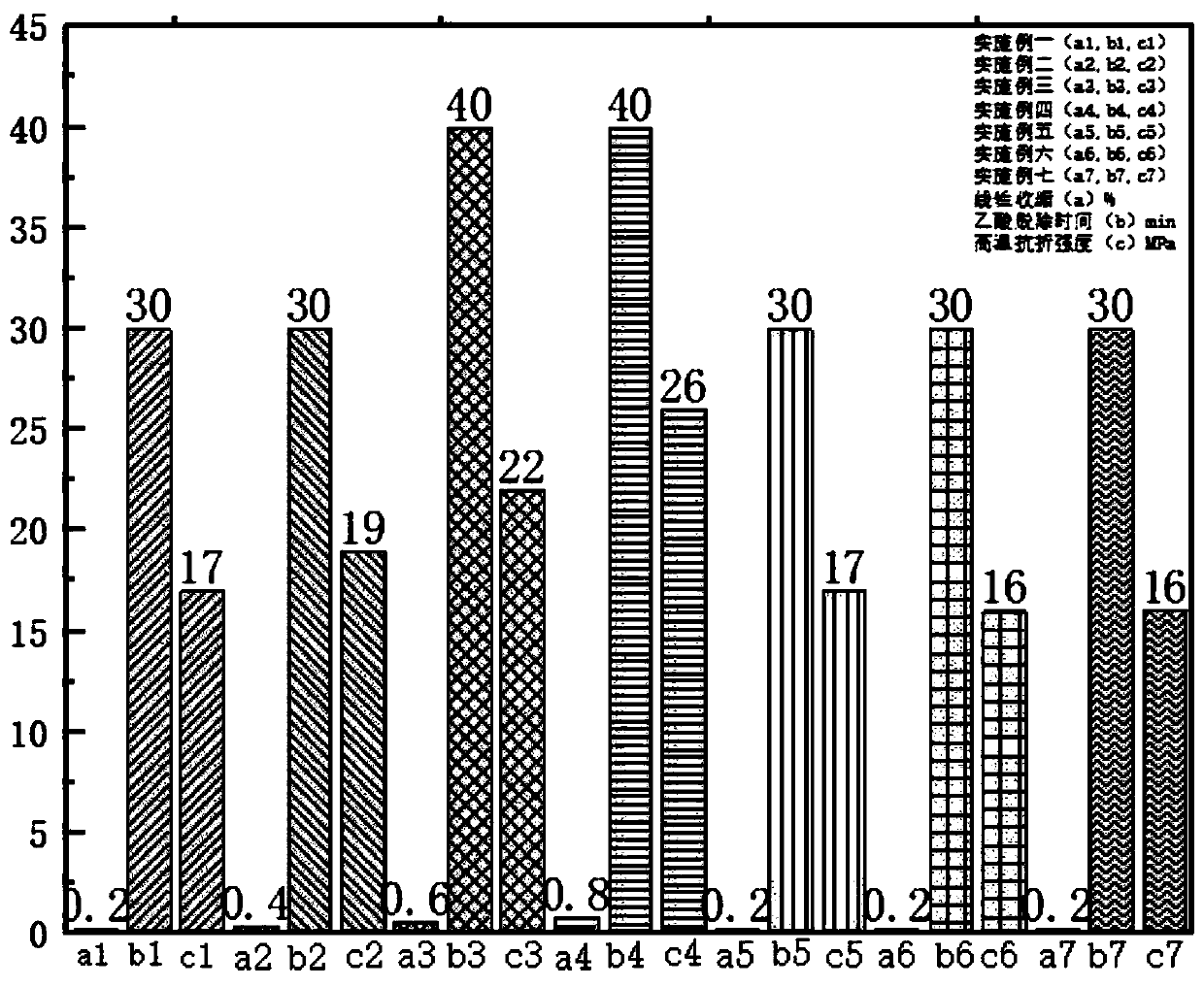

Examples

preparation example Construction

[0022] The invention provides a method for preparing an easy-to-remove ceramic core, comprising the following steps:

[0023] (1) mixing lanthanum oxide powder, calcium oxide powder and zirconium oxide powder to obtain a mixed material;

[0024] (2) Dry pressing the mixed material to obtain a biscuit;

[0025] (3) Sintering the green compact to obtain an easy-to-remove ceramic core.

[0026] The invention mixes lanthanum oxide powder, calcium oxide powder and zirconium oxide powder to obtain a mixed material. In the present invention, the mass ratio of the lanthanum oxide powder, calcium oxide powder and zirconium oxide powder is preferably (60-80): (5-10): (10-30), more preferably (65-75): (6~8): (20~25).

[0027] In the present invention, the particle size of the lanthanum oxide powder is preferably 100-325 mesh, more preferably 200 mesh. In the present invention, before the mixing, it is also preferred to pre-calcine the lanthanum oxide powder, the temperature of the pr...

Embodiment 1

[0044] The lanthanum oxide powder of 200 meshes pre-fired, the calcium oxide powder of 200 meshes, the zirconia powder of 2000 meshes and the PVB ethanol liquid are mixed by ball milling to make a mixed material; in the mixed material, the addition amount of the lanthanum oxide powder is 80wt %, the addition of calcium oxide powder is 5wt.%, the addition of zirconia powder is 10wt.%, the addition of PVB ethanol liquid is 5wt.%; the balls used for mixing in the ball mill are zirconia balls, The ball-to-material ratio is 2:1, and the ball-milling mixing time is 12 hours; when the ball-milling mixing is completed, the obtained powder is sieved to get zirconia balls, and then the under-sieve is dried at 120°C to obtain mixed materials;

[0045] Prepare the ceramic core by dry pressing, put the mixed material into a stainless steel mold, obtain the required ceramic core blank on a mechanical press, control the pressure of dry pressing to 20MPa, and keep the pressure for 2min, get ...

Embodiment 2

[0048] The 200 mesh lanthanum oxide powder, the 200 mesh calcium oxide powder, the 2000 mesh zirconium oxide powder and the PVB ethanol liquid that have been pre-fired are ball milled and mixed to make a mixed material; in the mixed material, the added amount of the lanthanum oxide powder is 75wt %, the addition of calcium oxide powder is 5wt.%, the addition of zirconia powder is 15wt.%, the addition of PVB ethanol liquid is 5wt.%; the balls used for mixing in the ball mill are zirconia balls, The ball-to-material ratio is 2:1, and the ball-milling mixing time is 12 hours; when the ball-milling mixing is completed, the obtained powder is sieved to get zirconia balls, and then the under-sieve is dried at 120°C to obtain mixed materials;

[0049] Prepare the ceramic core by dry pressing, put the mixed material into a stainless steel mold, obtain the required ceramic core blank on a mechanical press, control the pressure of dry pressing to 20MPa, and keep the pressure for 2min, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com