Constructible SiCp/Al matrix composite and preparation method thereof

An aluminum-based composite material and structure technology, applied in ceramic products, other household appliances, applications, etc., can solve the problems of uncontrollable addition of SiC particles, uncontrollable content of SiC particles, uncontrollable degree of bonding of aluminum alloys, etc., and achieve expansion The effect of low coefficient, improved coating strength and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

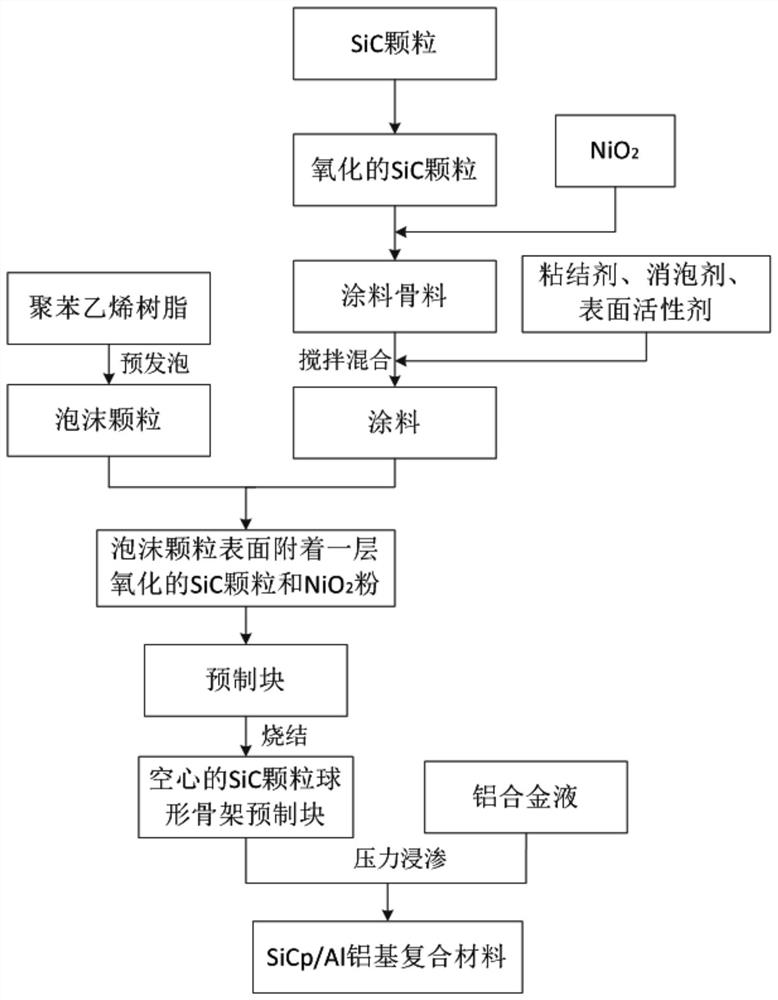

[0042] see figure 1 , a method for preparing a structurable SiCp / Al aluminum matrix composite material, comprising the following steps:

[0043] S1, preparation of foam particles

[0044] Pass steam into the stirred tank to preheat, add polystyrene resin (EPS) beads into the preheated stirred tank, and then pass steam to heat for pre-foaming; wherein, the diameter of the foamed particles after foaming is 0.1 ~2mm;

[0045] S2, oxidized SiC particles

[0046] Put the SiC particles in an industrial microwave sintering furnace, and perform a high-temperature oxidation reaction at 1200 ° C for 3 hours, so that a layer of SiO is formed on the surface of the SiC particles. 2 The oxide layer can increase the wettability of SiC particles and aluminum alloy; among them, the particle size of SiC particles is 5-30 μm;

[0047] S3, preparation of coating aggregate

[0048] oxidized SiC particles with NiO 2Powder mixed to form paint aggregate; among them, NiO 2 The mass of the powde...

Embodiment 2

[0067] A kind of preparation method of structurable SiCp / Al aluminum matrix composite material is the same as the method of embodiment 1, and its difference is:

[0068] In S2, the temperature of the high temperature oxidation reaction is 1300°C, and the reaction time is 2h;

[0069] S3, NiO 2 The mass of the powder is 5% of the mass of the oxidized SiC particles;

[0070] In S4, the binding agent is ethyl orthosilicate and white latex, and the mass of the white latex is 3wt% of the mass of the hydrolyzed ethyl orthosilicate. The mass ratio of tetraethyl orthosilicate to SiC particles is 1:4. The mass of the defoaming agent is 0.2wt% of the mass of the binder; the mass of the surfactant is 0.3wt% of the mass of the binder.

[0071] In S5, the volume ratio of paint to foam particles is 1:5;

[0072] In S6, in the drying oven, the drying and curing temperature is 60°C, and the time is 5 hours;

[0073] In the high temperature furnace, the sintering temperature is 900°C, and...

Embodiment 3

[0078] A kind of preparation method of structurable SiCp / Al aluminum matrix composite material is the same as the method of embodiment 1, and its difference is:

[0079] In S2, the temperature of the high temperature oxidation reaction is 1000°C, and the reaction time is 3h;

[0080] S3, NiO 2 The mass of the powder is 2% of the mass of the oxidized SiC particles;

[0081] In S4, the binding agent is hydrolyzed orthosilicate and white latex, and the mass of the white latex is 2 wt% of the mass of the hydrolyzed orthosilicate. The mass ratio of tetraethyl orthosilicate to SiC particles is 1:1. The mass of the defoaming agent is 0.1 wt% of the mass of the binder; the mass of the surfactant is 0.2 wt% of the mass of the binder.

[0082] In S5, the volume ratio of paint to foam particles is 1:3;

[0083] In S6, in the drying oven, the drying and curing temperature is 40°C, and the drying time is 8 hours;

[0084] In the high temperature furnace, the sintering temperature is 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com