Method for removing pyridine base in mixed phenol

A technology of mixing phenol and pyridine bases, which is applied in the field of coal chemical industry, can solve the problems that the chroma cannot be guaranteed and the purity is difficult to be further improved, and achieve the effects of improving efficiency, improving purity, and good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment provides a method for removing pyridine bases in mixed phenols, comprising the following steps,

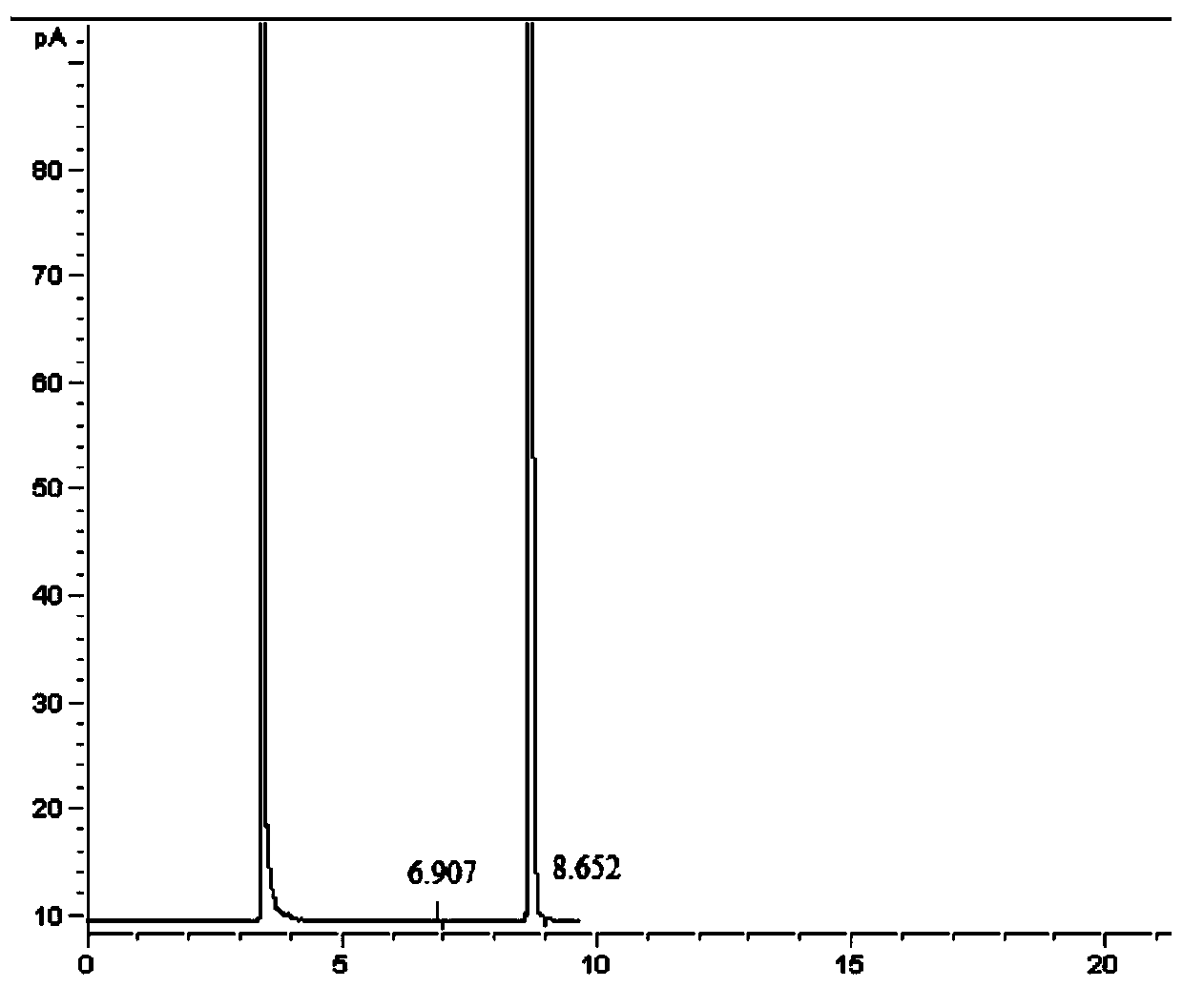

[0040] Mix 1000ml of mixed phenol with 15ml of oxalic acid aqueous solution with a volume fraction of 0.01%, and react at 45°C for 0.5h to obtain the first intermediate product. The first intermediate product is a mixture of mixed phenol and oxalic acid solution, including mixed phenol and oxalic acid High boiling point substances formed by solution reaction, including other substances that have not reacted with oxalic acid solution;

[0041] Then, the first intermediate product of 1000ml is mixed with 1.5ml aqueous sulfuric acid solution with a volume fraction of 2%, and reacted for 1h at 55°C to obtain the second intermediate product, which is not mixed with oxalic acid solution in the first intermediate product. High boiling point substances formed by the reaction of other reacted substances with sulfuric acid solution, including high boiling point substa...

Embodiment 2

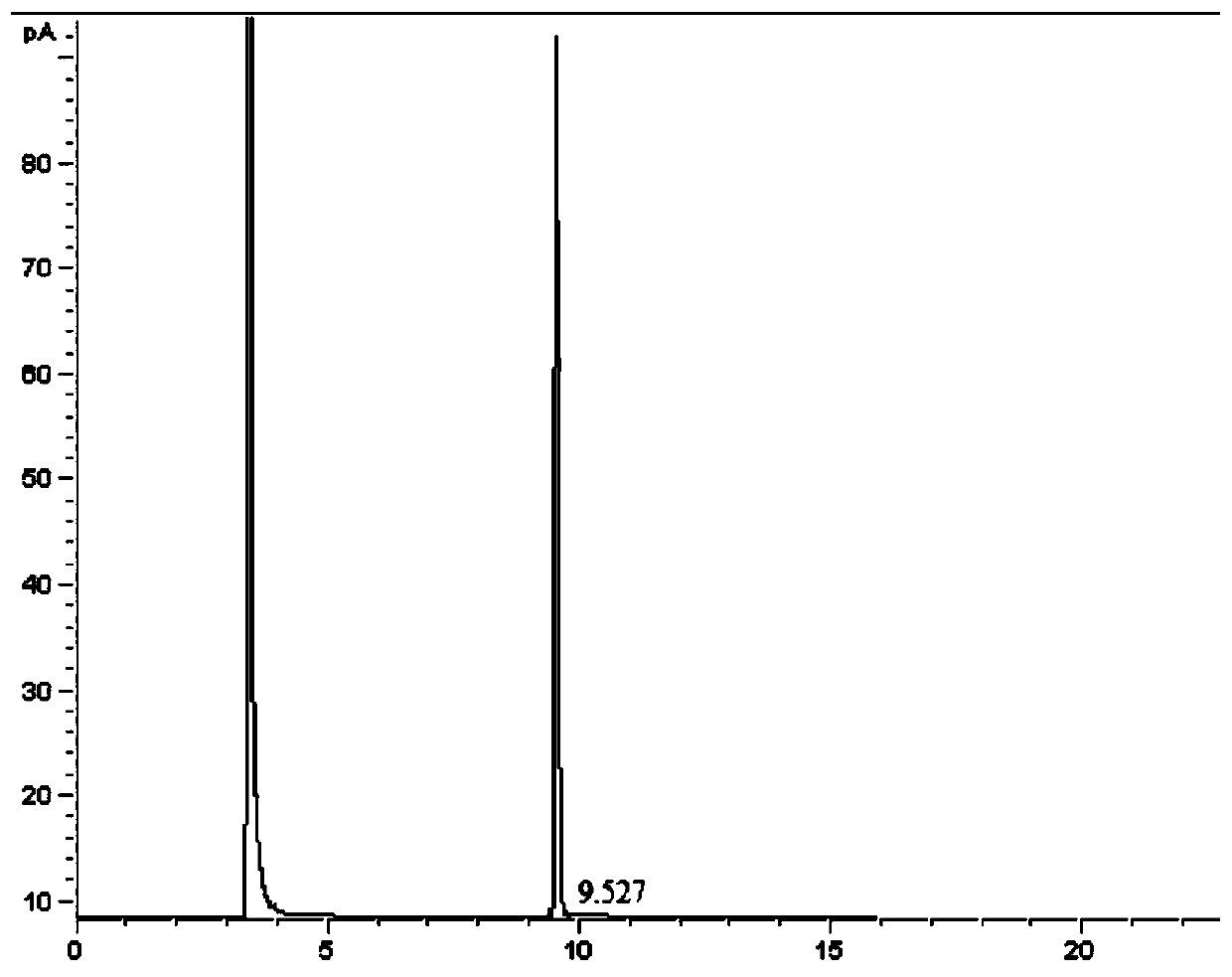

[0045] This embodiment provides a method for removing pyridine bases in mixed phenols, comprising the following steps,

[0046] Mix 1000ml of mixed phenol with 15ml of oxalic acid aqueous solution with a volume fraction of 0.1% and react at 60°C for 0.5h to obtain the first intermediate product, which is a mixture of mixed phenol and oxalic acid solution, including mixed phenol High-boiling substances formed by reacting with oxalic acid solution, including other substances that have not reacted with oxalic acid solution;

[0047]Then 1000ml of the first intermediate product is reacted with 1.5ml of sulfuric acid aqueous solution with a volume fraction of 1% at 50°C for 1h to obtain the second intermediate product, which is the other intermediate product that has not reacted with the oxalic acid solution in the first intermediate product. High boiling point substances formed by the reaction of substances with sulfuric acid solution, including high boiling point substances forme...

Embodiment 3

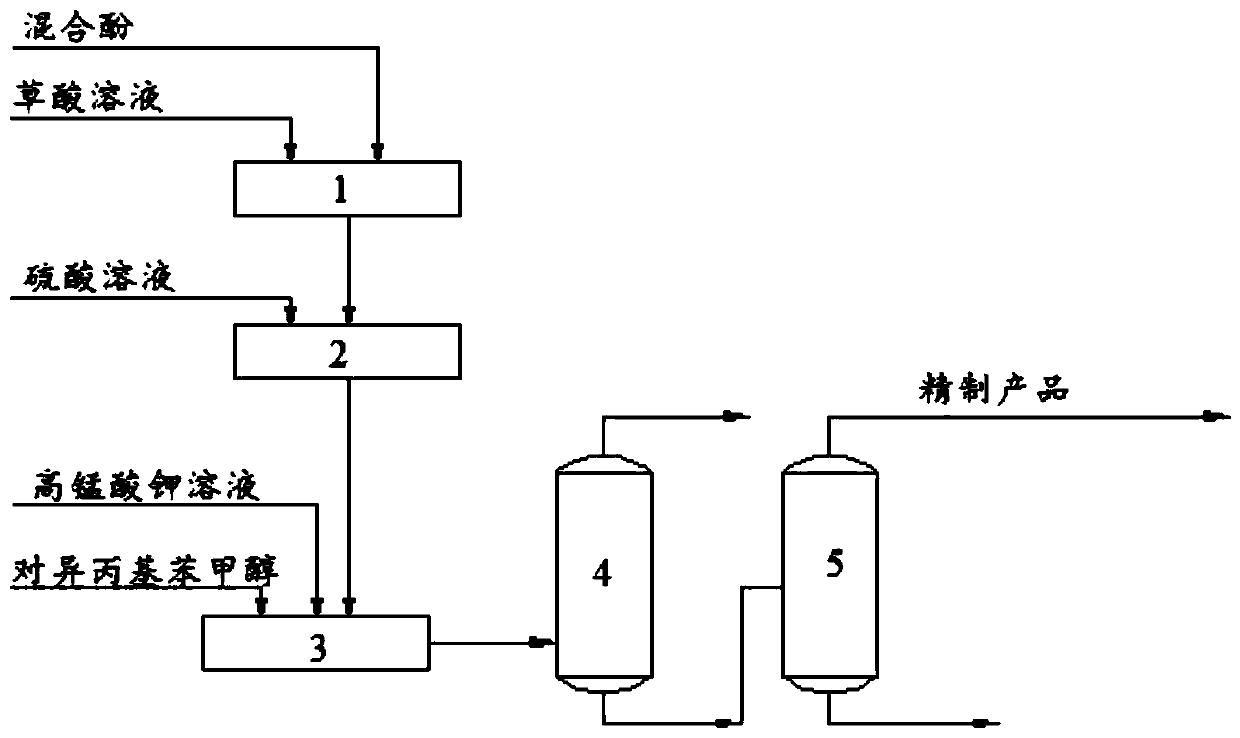

[0051] This embodiment provides a method for removing pyridine bases in mixed phenols, the process of which is shown in figure 1 , including the following steps,

[0052] Mix 1000ml of mixed phenols with 15ml of oxalic acid aqueous solution with a volume fraction of 0.05%, and react at 50°C for 0.5h to obtain the first intermediate product;

[0053] Then 1000ml of the first intermediate product was mixed with 1.5ml of sulfuric acid aqueous solution with a volume fraction of 1.5%, and reacted at 50°C for 1h to obtain the second intermediate product;

[0054] 1000ml of the second intermediate product was mixed with 8ml of potassium permanganate aqueous solution with a volume fraction of 3.5% and reacted at 50°C for 0.5h to obtain the third intermediate product;

[0055] The third intermediate product is continuously transported to the dehydration tower, the third intermediate product removes light components and water in the dehydration tower, enters the slag removal tower, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com