A prefabricated building wall

A building wall and prefabricated technology, applied in buildings, building components, building structures, etc., can solve problems such as poor thermal insulation effect, poor ventilation effect, stuffy room, etc., to achieve enhanced thermal insulation effect, light weight, and keep dry and cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below by means of specific embodiments:

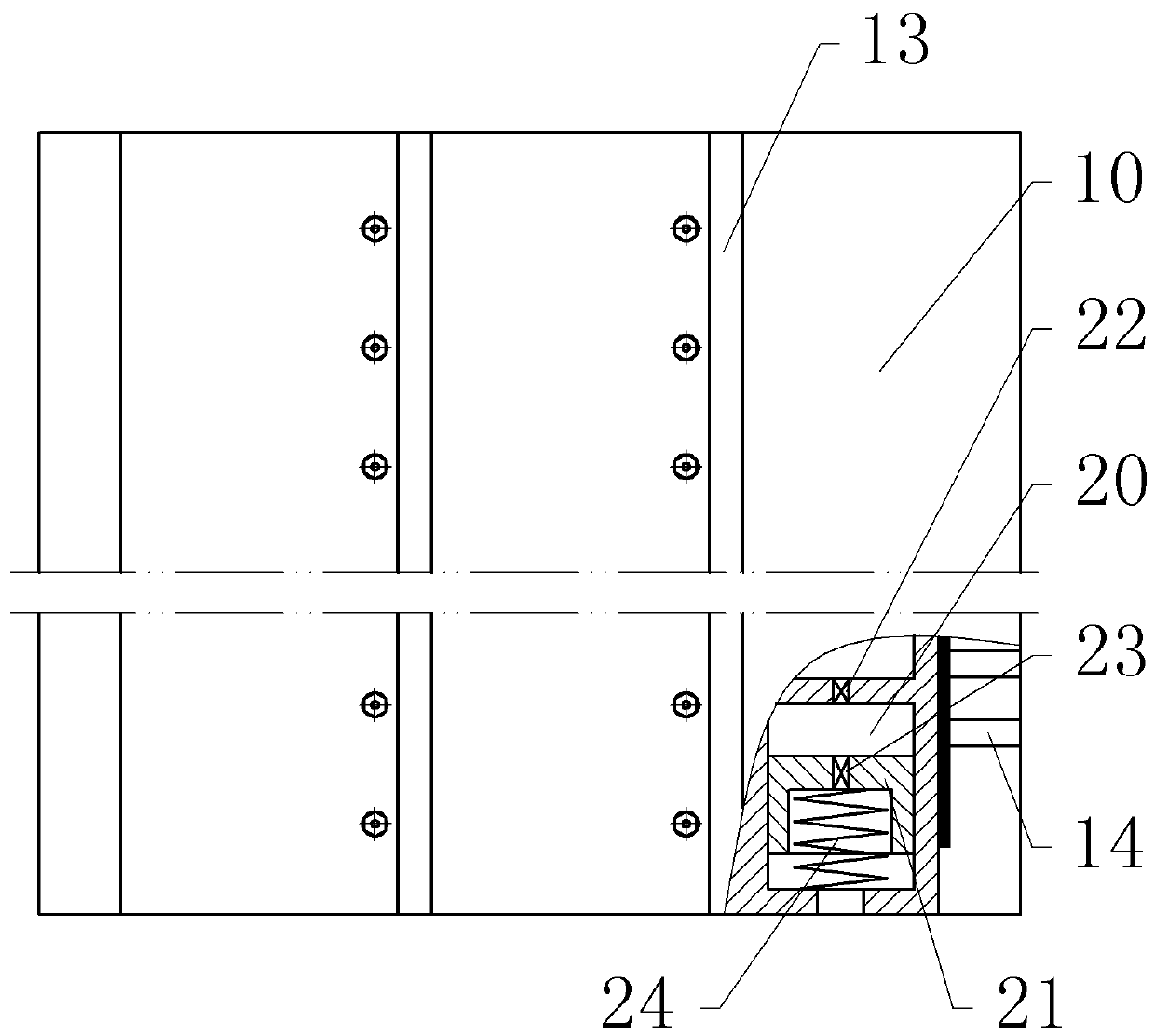

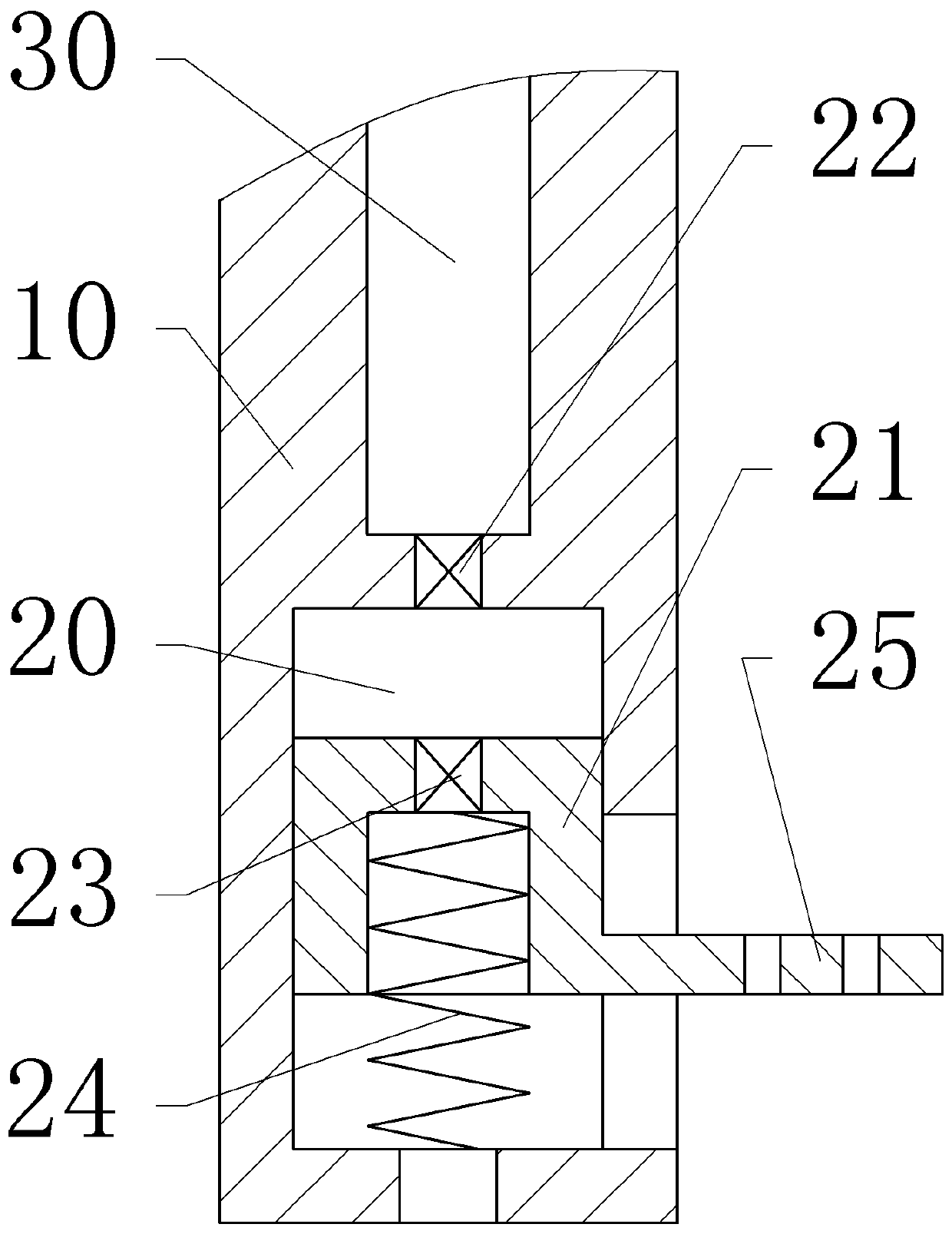

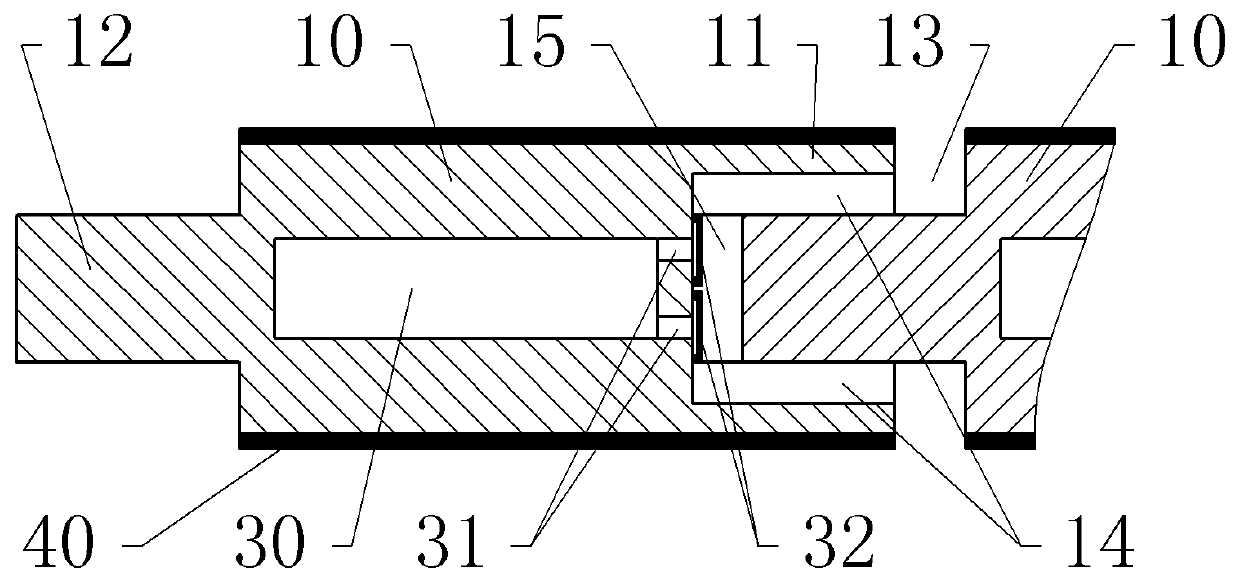

[0029] The reference signs in the drawings of the description include: wall unit 10, pressurized chamber 20, inner chamber 30, first connecting portion 11, second connecting portion 12, windshield groove 13, air duct 14, ventilation gap 15, second A piston 21, a first one-way valve 22, a second one-way valve 23, a clip spring 24, a floor suspension 25, an opening 31, an elastic layer 32, a heat insulating layer 40, a cylinder body 50, a second piston 51, a connecting rod 52.

[0030] The prefabricated building wall of this embodiment is composed of several wall units 10, and the wall units 10 are in the shape of vertical strips. like figure 1 , figure 2 and image 3 As shown, the right side of the wall unit 10 is provided with a first connecting portion 11 , and the left side of the wall unit 10 is provided with a second connecting portion 12 . The first connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com