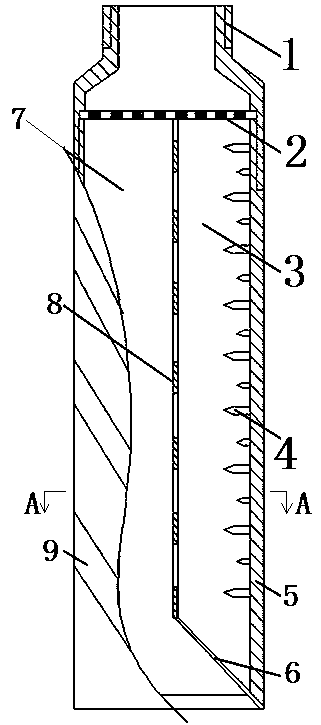

Reverse circulation sand washing device

A technology of reverse circulation and sand washing, which is applied in the direction of flushing boreholes, boreholes/well components, and earthwork drilling and production, and can solve the problems of easy formation of sand beds in horizontal sections, low sand washing efficiency, and weak sand-carrying capacity, achieving Prevent sundries from clogging the sand flusher and improve sand flushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 5

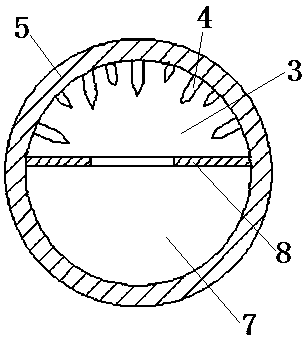

[0025] In the specific embodiment 5 of the reverse circulation sand washing device of the present invention, in this embodiment, a spiral deflector is arranged on the outer circumference of the cylinder to form a spiral deflector structure, and the others are the same as in embodiment 1, and no longer repeat.

specific Embodiment 6

[0026] The specific embodiment 6 of the reverse circulation sand washing device of the present invention, in this embodiment, the filter element is a mesh structure, and the others are the same as the embodiment 1, and will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com