Timing blowdown valve

A sewage valve, timing technology, applied in valve details, valve device, valve shell structure, etc., can solve the problems of sediment blocking, easy blocking, trouble, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

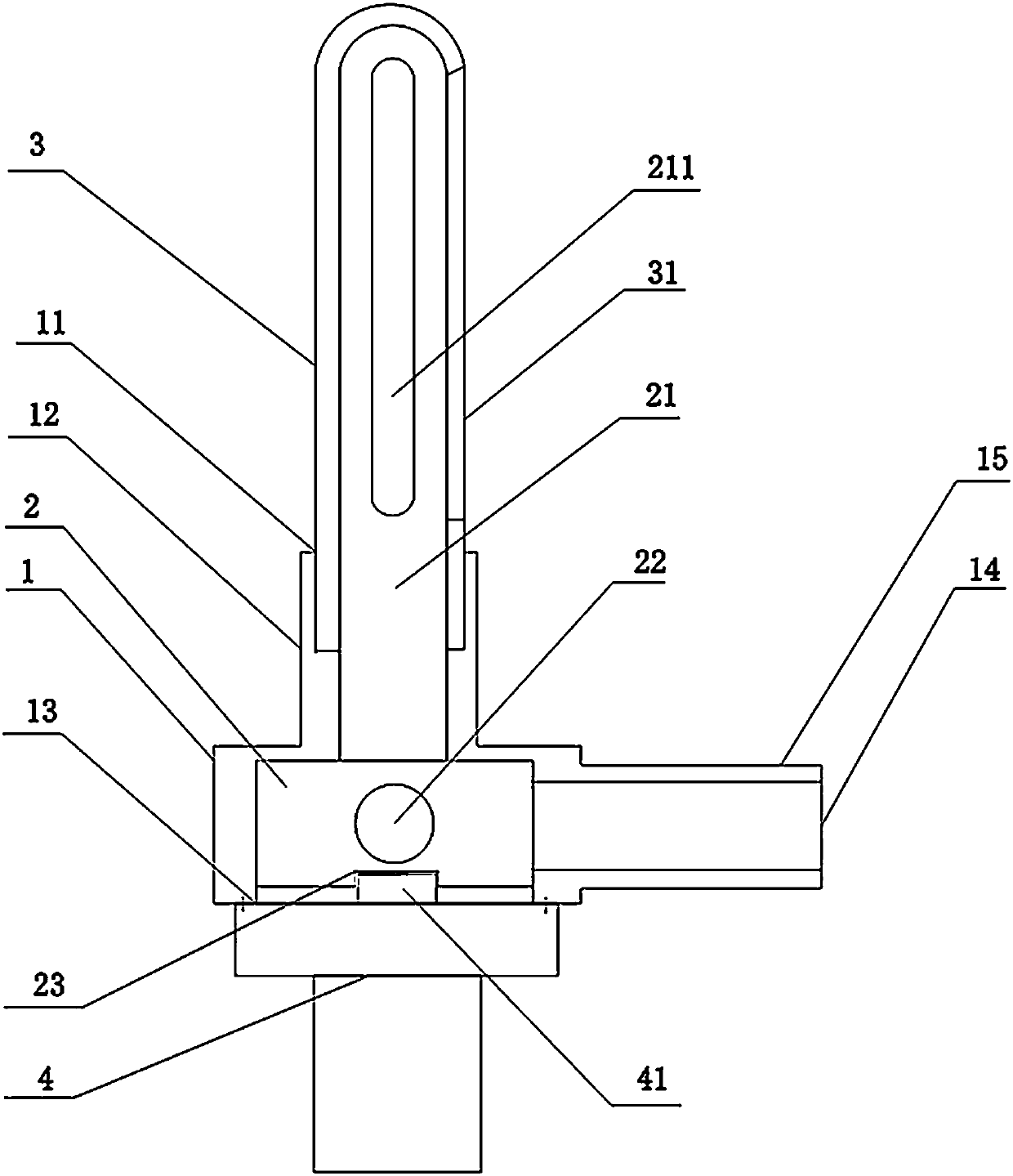

[0014] The timing sewage valve is composed of a valve body (1), a valve core (2), a guide cover (3), and a timing angular positioning motor (4), and is characterized in that a water inlet (11) is reserved above the valve body (1). ), an outer wire (12) is reserved on the outside of the water inlet (11) to facilitate connection with the sewage outlet of the sedimentation tank, a valve core insertion hole (13) is reserved at the bottom, a water outlet (14) is reserved on the side, and the water outlet is reserved The connection wire port (15) is easy to connect with the sewage pipeline, and the water inlet (11), the water outlet (14), and the valve core insertion hole (13) are connected to each other; above the valve core (2) is the tongue tube (21), A long strip hole (211) is reserved on the side of the shedding pipe (21), a bridging water hole (22) is reserved on the side of the valve core (2), and a timing angle positioning motor connection hole (23) is reserved at the bottom,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com