Detachable premixed diesel combustor with controllable exhaust components

A detachable burner technology, which is applied in the field of detachable premixed diesel burners, can solve the problem of small flow and achieve the effect of simple structure, reasonable design and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

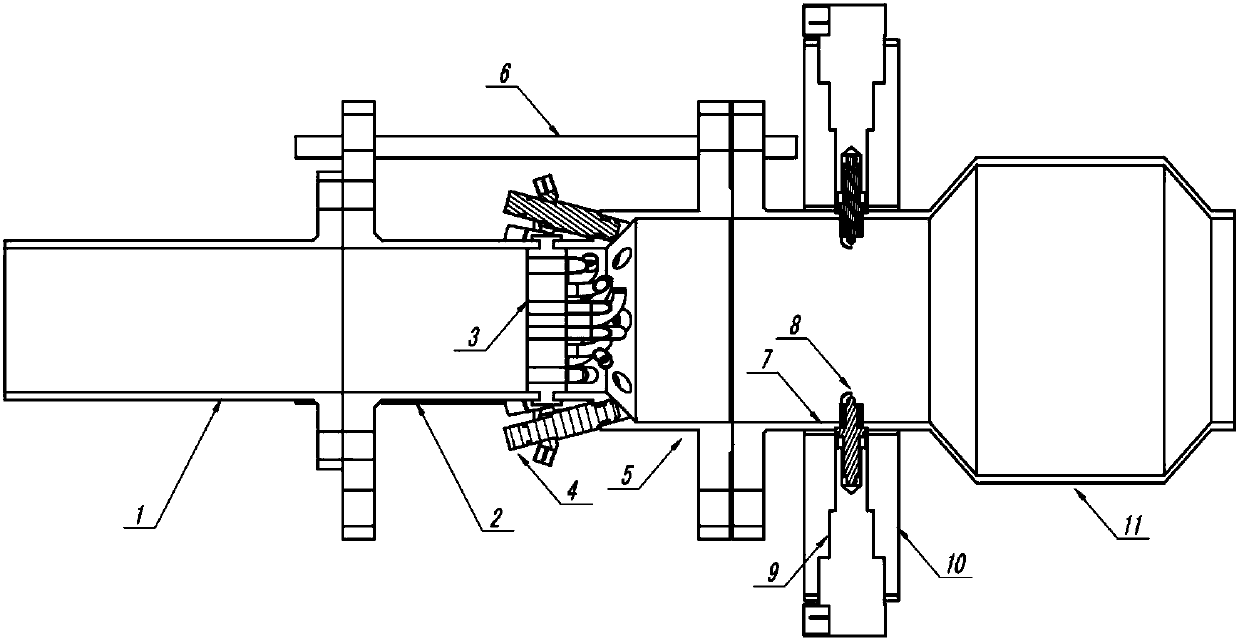

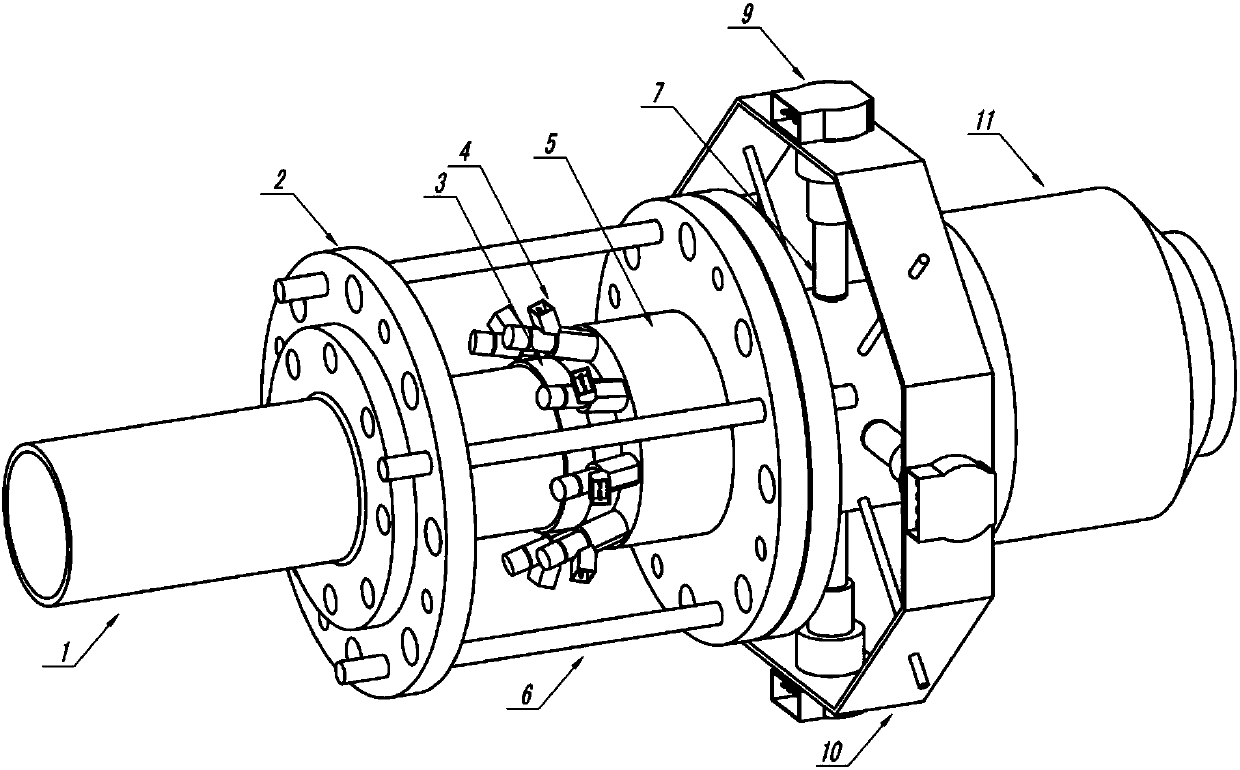

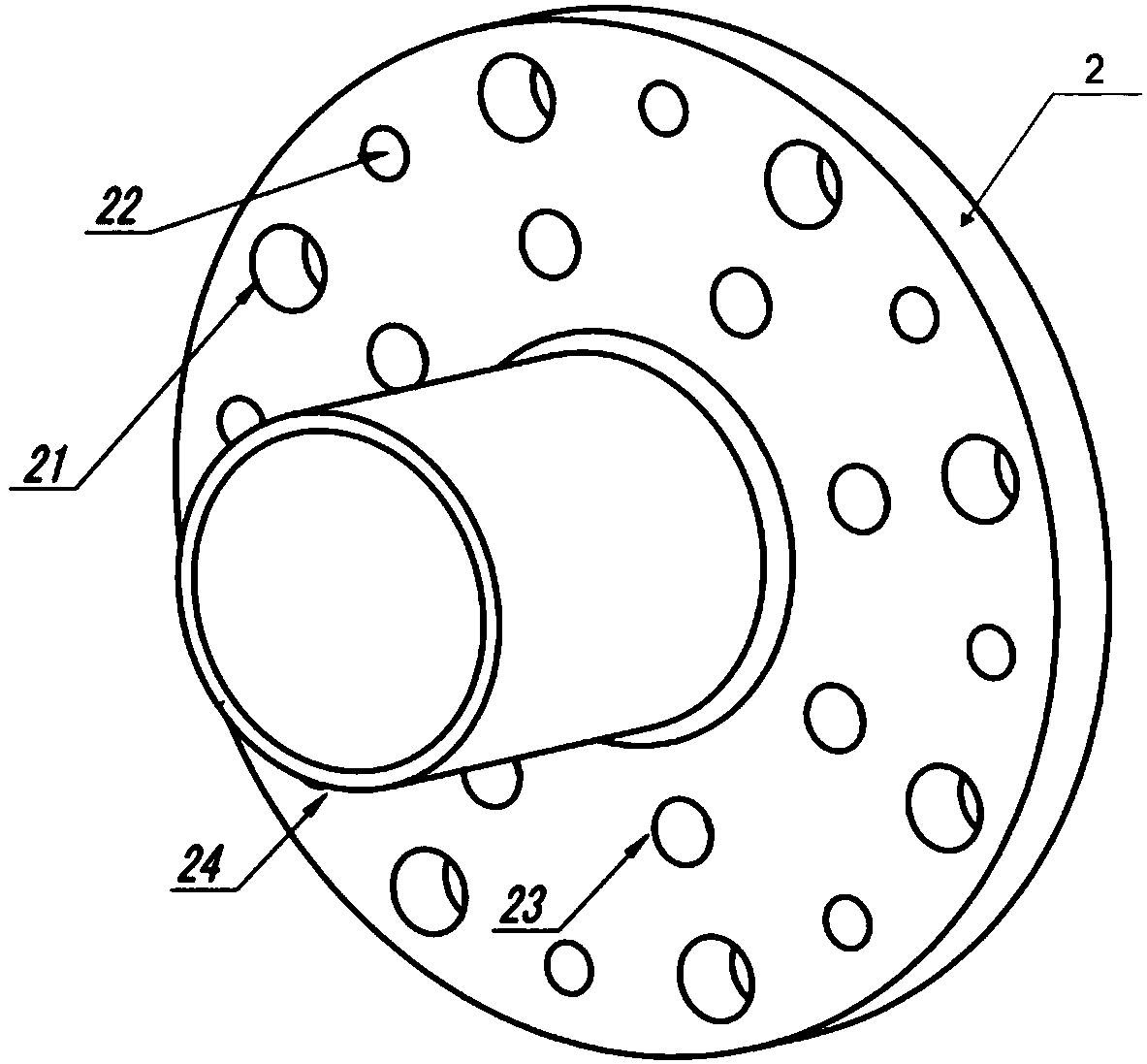

[0026] Such as Figure 1 to Figure 9 As shown, the present invention includes intake section 1, front fixed section 2, swirl plate 3, fuel injector group 4, rear fixed section 5, screw mandrel 6, mixing section 7, spark plug group 8, ignition coil 9, support 10, Combustion chamber 11, oil pipe fixing hole 21, screw rod fixing hole 22, air intake section fixing hole 23 are arranged on the front fixing section 2, and the flange is installed between the air inlet section 1 and the front fixing section 2 through the air inlet section fixing hole 23 The bolts are fixed, and the inner ring layer elbow system 31, the second ring layer elbow system 32, the outer ring layer elbow system 33, the front end slot 34, and the rear end slot 35 are respectively arranged on the vortex plate 3, and the rear fixing section 5 includes Front cavity 51, cavity slope 52, cavity inner surface 53, front-end pipeline 54, front-end slope 55, injector socket 56, connecting flange 57, the end pipeline 24 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com