Energy-saving heating furnace

A technology of heating furnace and heating sheet, which is applied in the direction of electric furnace heating, lighting and heating equipment, furnace, etc., which can solve the problems of large heat, energy consumption, increased economic expenditure, etc., and achieve the effect of increasing the heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

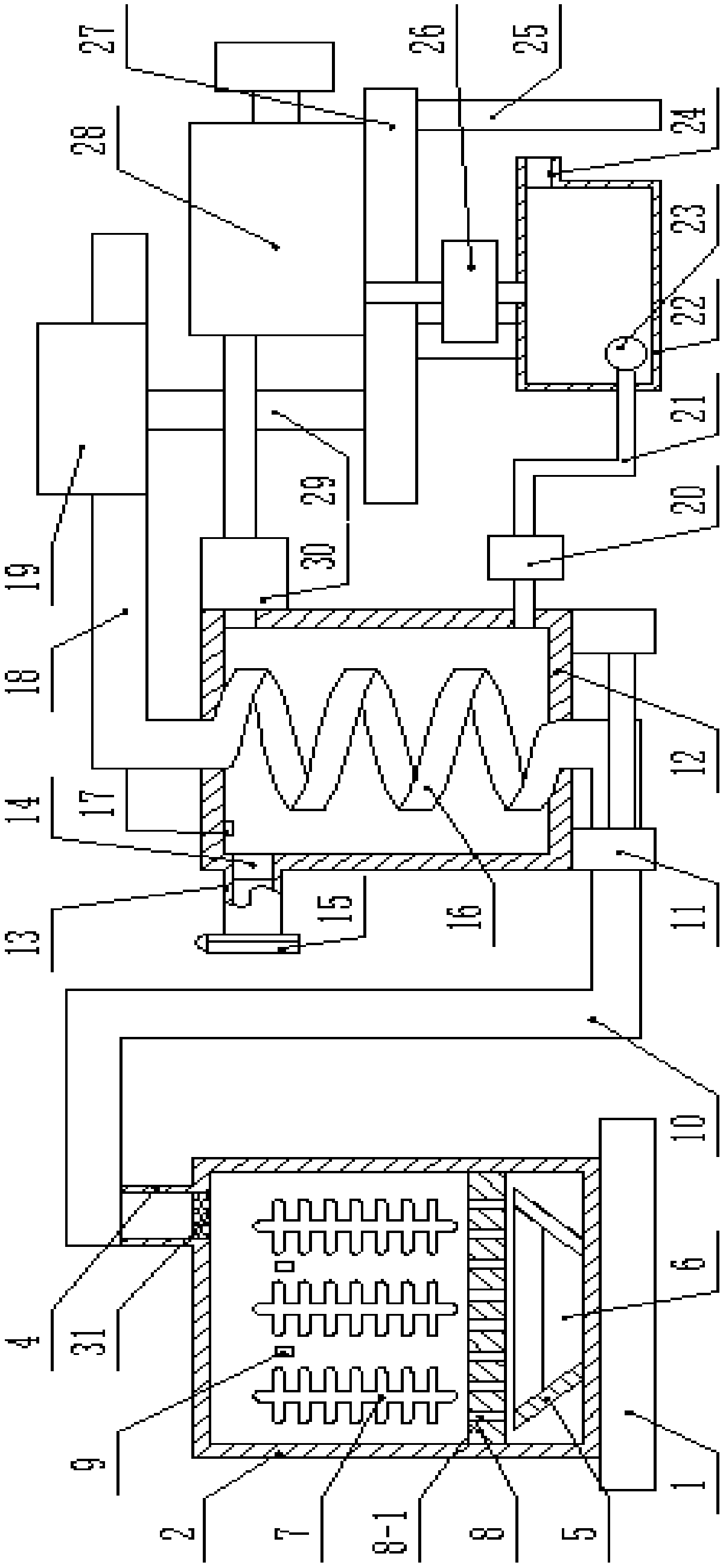

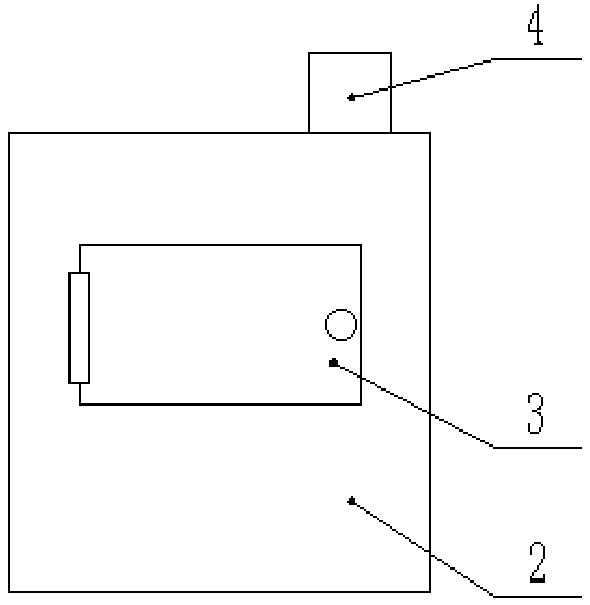

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

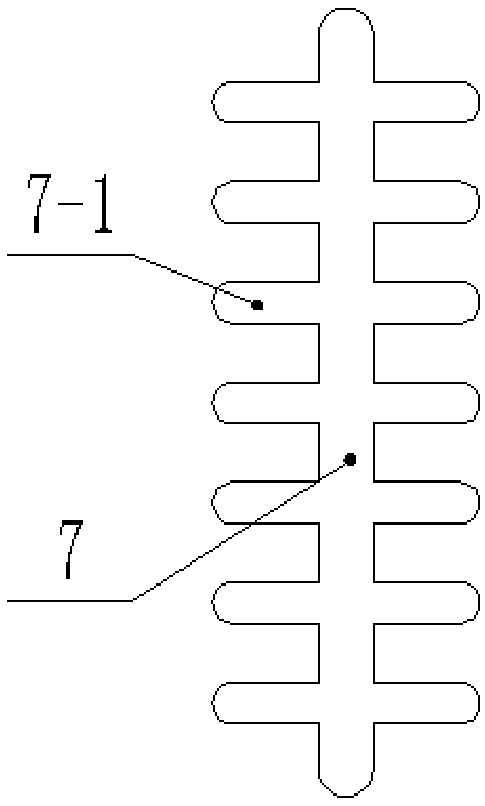

[0017] Such as Figure 1 to Figure 4 As shown, an energy-saving heating furnace includes a base 1, a furnace body 2 is fixed on the upper end of the base 1, a funnel-shaped shell 5 is fixed on the inner lower end of the furnace body 2, and the middle of the funnel-shaped shell 5 is fixed There is a heating device 6, the upper end of the funnel-shaped housing 5 is provided with a baffle 8 fixed inside the furnace body 2, the baffle 8 is horizontally arranged, and the baffle 8 is provided with several through holes 8-1 , the inner wall of the body of furnace 2 is provided with several heating fins 7, the side of the heating fin 7 is provided with branch heating fins 7-1, and the inner wall of the body of furnace 2 is provided with two temperature sensors 9, the The upper end of the furnace body 2 is provided with a smoke outlet A4, the inside of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com