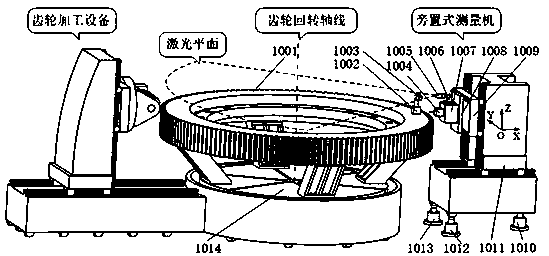

A method for establishing a measuring coordinate system of a side-mounted measuring machine for large gears

A technology for measuring coordinate systems and large gears, applied to measuring devices, optical devices, instruments, etc., can solve the problems of low precision, achieve the effect of improving the establishment of precision and avoiding its own precision constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0054] A method for establishing a measuring coordinate system for a side-mounted measuring machine for large gears, the specific steps are:

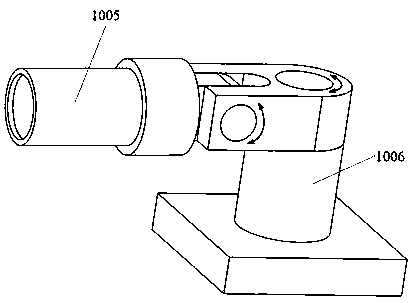

[0055] Step 1: Place the laser head 1005 on the measuring head mounting frame 1007 through its mounting base 1006, and ensure that the fan-shaped laser plane formed by the laser head 1005 outgoing beam is parallel to the XOY plane of the measuring machine coordinate system. The formation of the laser plane can be adopted It is formed by the known method of rotating laser beams, and can also be formed by using known optical elements such as ring mirrors or cylindrical lenses;

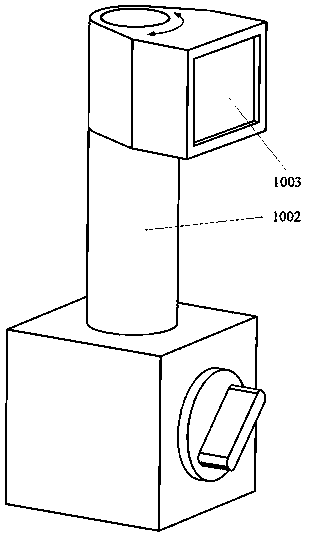

[0056] Step 2: Place the target 1003 on the upper surface of the gear 1001 and directly in front of the laser head 1005, set this position as P1 position, rotate the photosensitive surface of the target 1003 to face the laser, adjust the measuring machine so that the laser is perpendicular to the target plane and passes through the target center. Here the target ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com