Gluing method based on distributed pressure sensing technology

A sensing technology and pressure sensor technology, applied in the field of distributed pressure sensing technology, can solve the problems of poor bonding effect, uneven pressure distribution, etc., to avoid bonding quality problems, improve quality, and glue bonding operations. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make it easy to understand the technical means, creative features, achieved goals and effects of the present invention, the present invention is further described below.

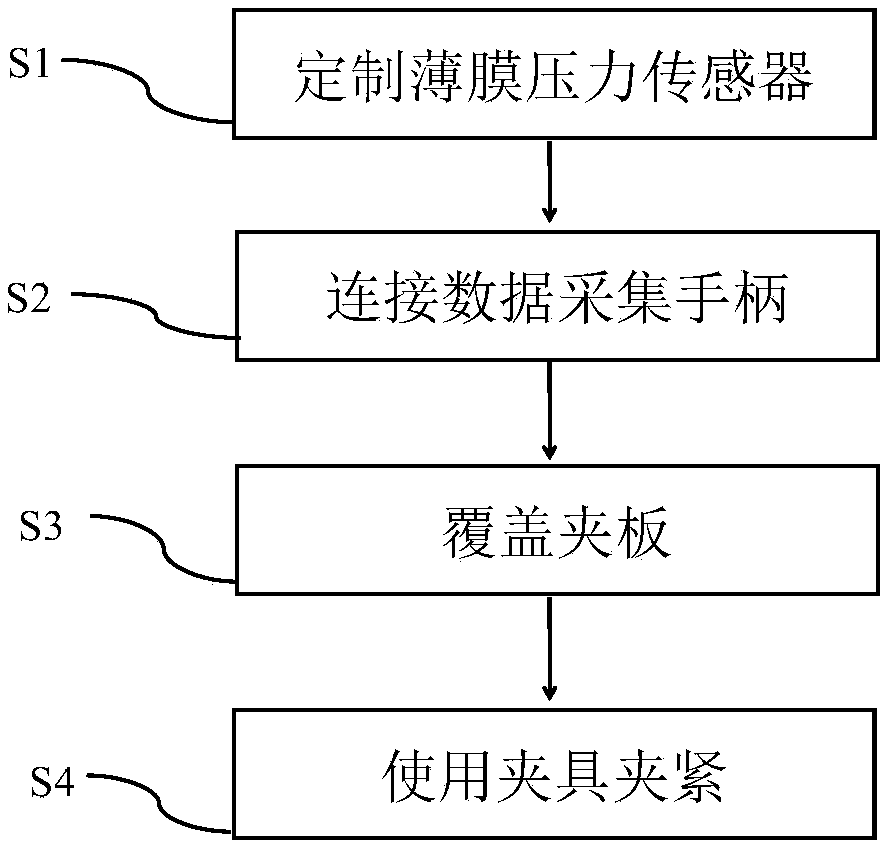

[0013] like figure 1 The method step diagram shown:

[0014] A glue bonding method based on distributed pressure sensing technology, the steps of the glue bonding method are:

[0015] S1) Customized film pressure sensor: Customize the film pressure sensor according to the size and shape of the glued area. The film pressure sensor is composed of a force-sensitive resistor array evenly distributed according to the glued area. The pressure generated by the splint on the glued area will change. The resistance of the force-sensitive resistor converts the pressure signal into a voltage signal through the voltage divider circuit;

[0016] S2) Connect the data acquisition handle: connect the film pressure sensor to the data acquisition handle, and connect the data acquisition handle to the compu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com