An optical cable high-altitude fusion splicing device

A fusion splicing and optical cable technology, applied in the field of optical cable high-altitude fusion splicing devices, can solve the problems of inconvenient portability, failure to timely failure, and long construction time, and achieve the effects of improving flexibility, reducing impact, and facilitating adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

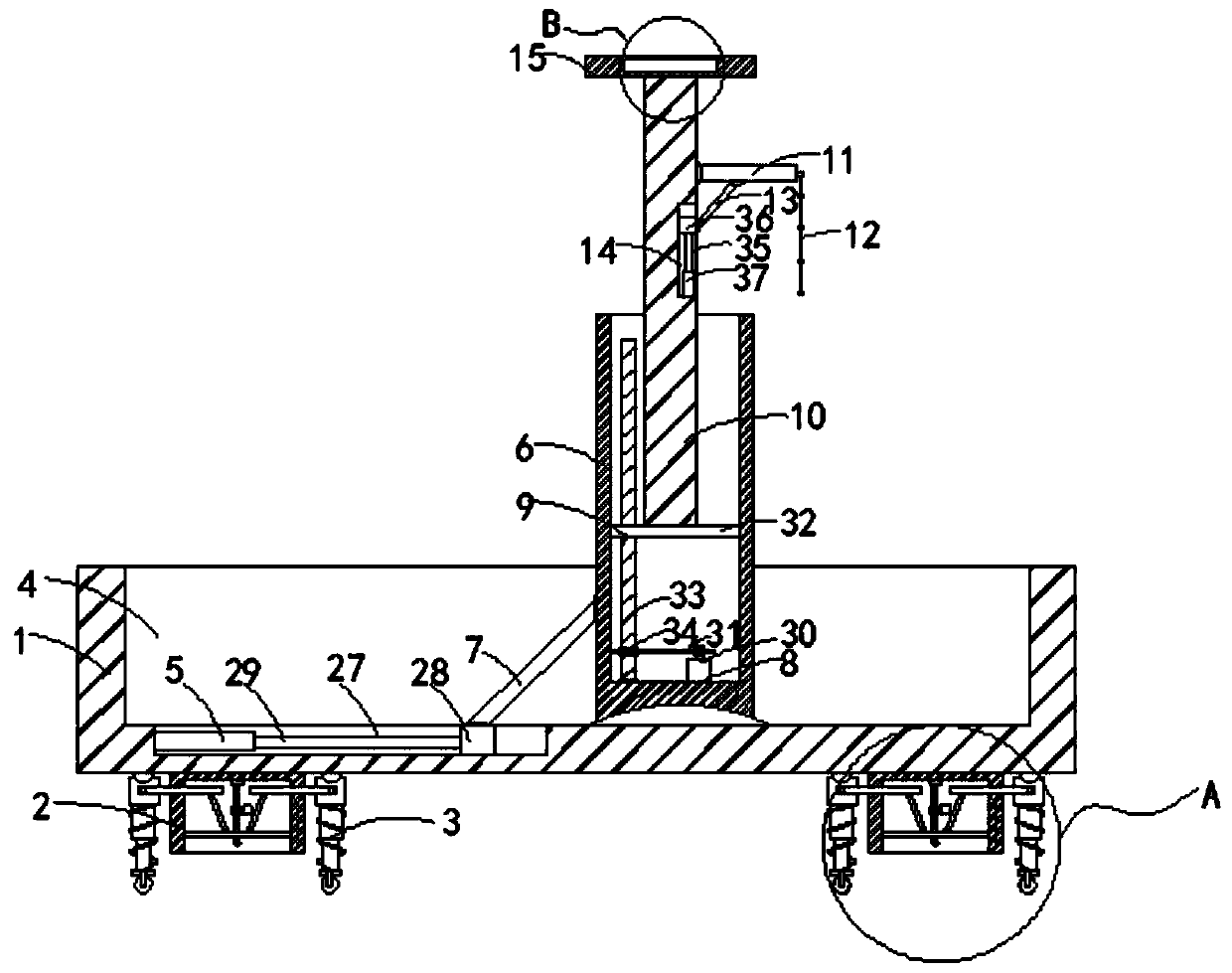

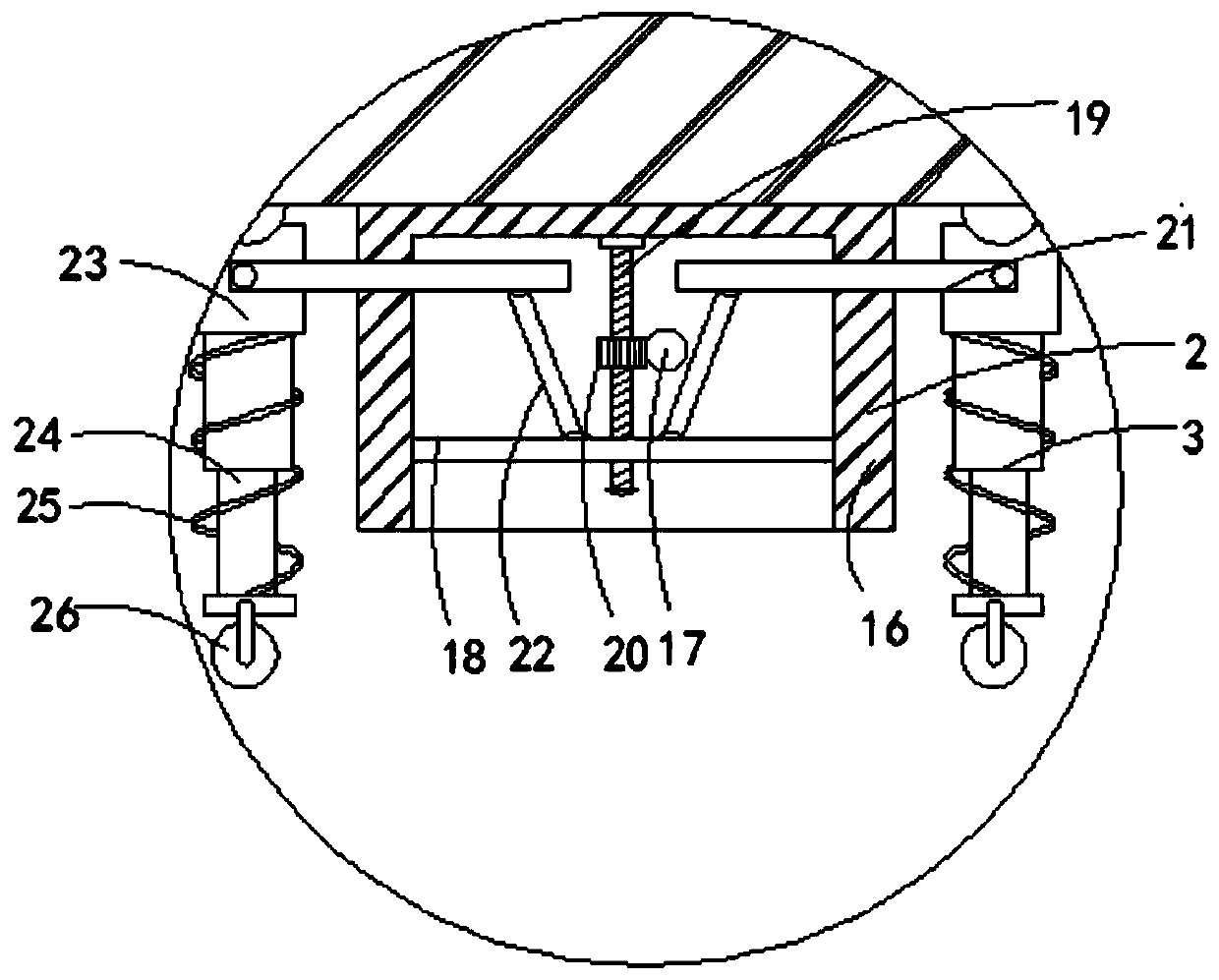

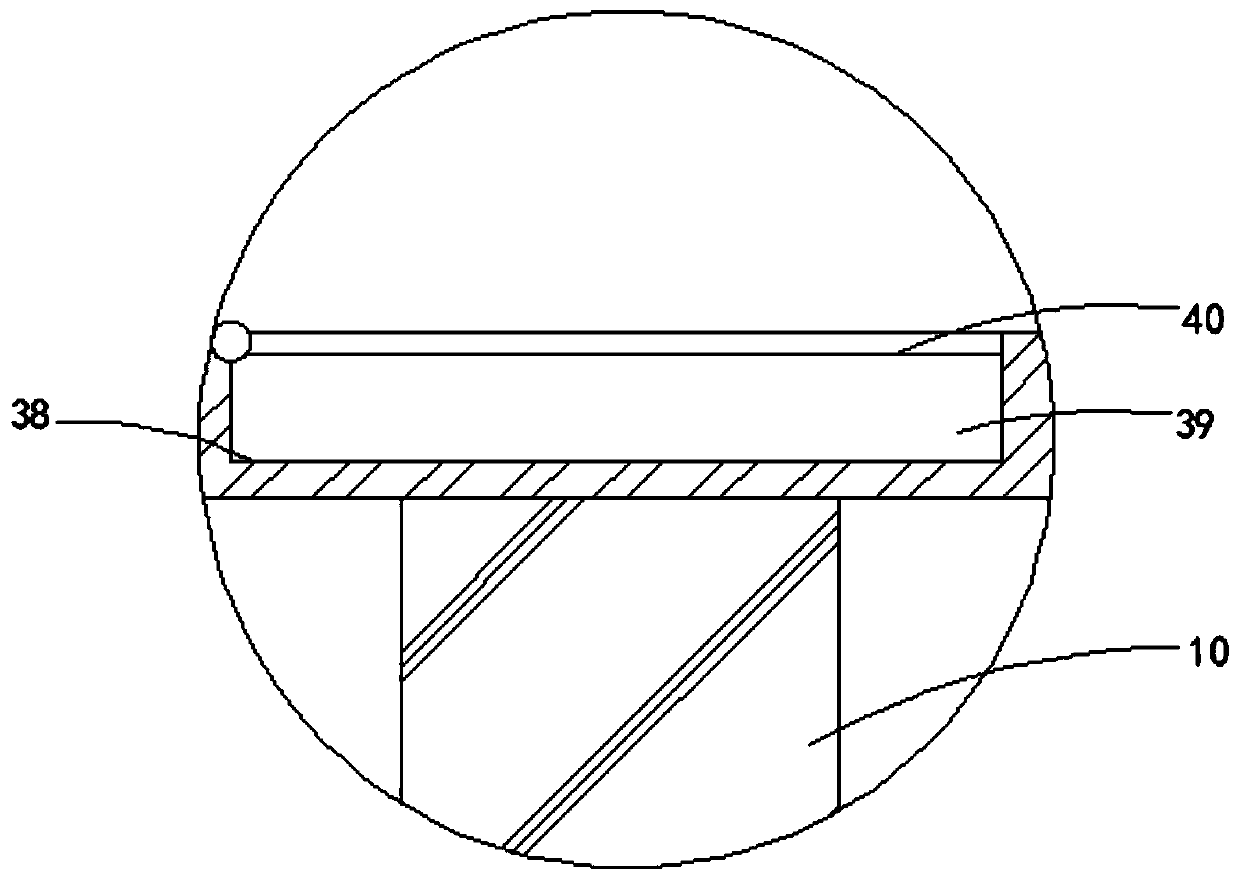

[0022] Such as Figure 1-4 As shown, a high-altitude fusion splicing device for optical cables includes a base 1. A plurality of control devices 2 are provided at the lower end of the base 1. The lower ends of the base 1 on the left and right sides of the control device 2 are rotatably connected with a moving mechanism 3. The upper end of the base 1 is provided with Groove 4, the bottom of the groove 4 is provided with a first sliding mechanism 5, the bottom of the groove 4 is rotatably connected with a first cylindrical barrel 6, and the opening of the first cylindrical barrel 6 is set upward, and the first cylindrical barrel 6 is close to the first One end side wall of the sliding mechanism 5 is rotationally connected with one end of the first linkage rod 7, and the other end of the first linkage rod 7 is rotationally connected with the first sliding mechanism 5. The bottom of the first cylindrical barrel 6 is provided with a rotating device 8, The first cylinder barrel 6 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com