Automatic identification method suitable for narrow scale pointer type instrument of transformer station

An automatic identification and substation technology, applied in the field of automatic identification, can solve the problems of inaccurate reading results, reading result errors, poor adaptability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

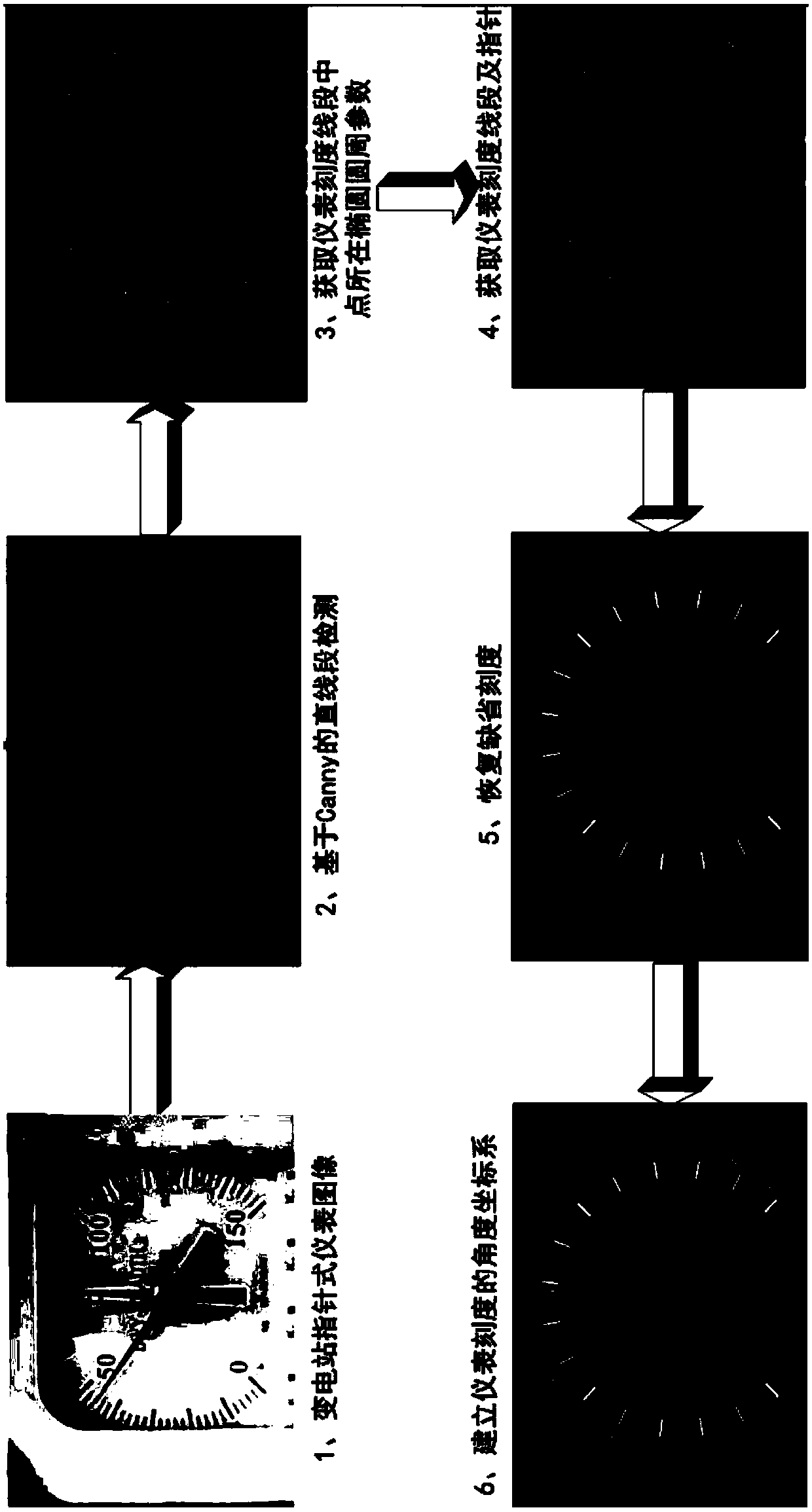

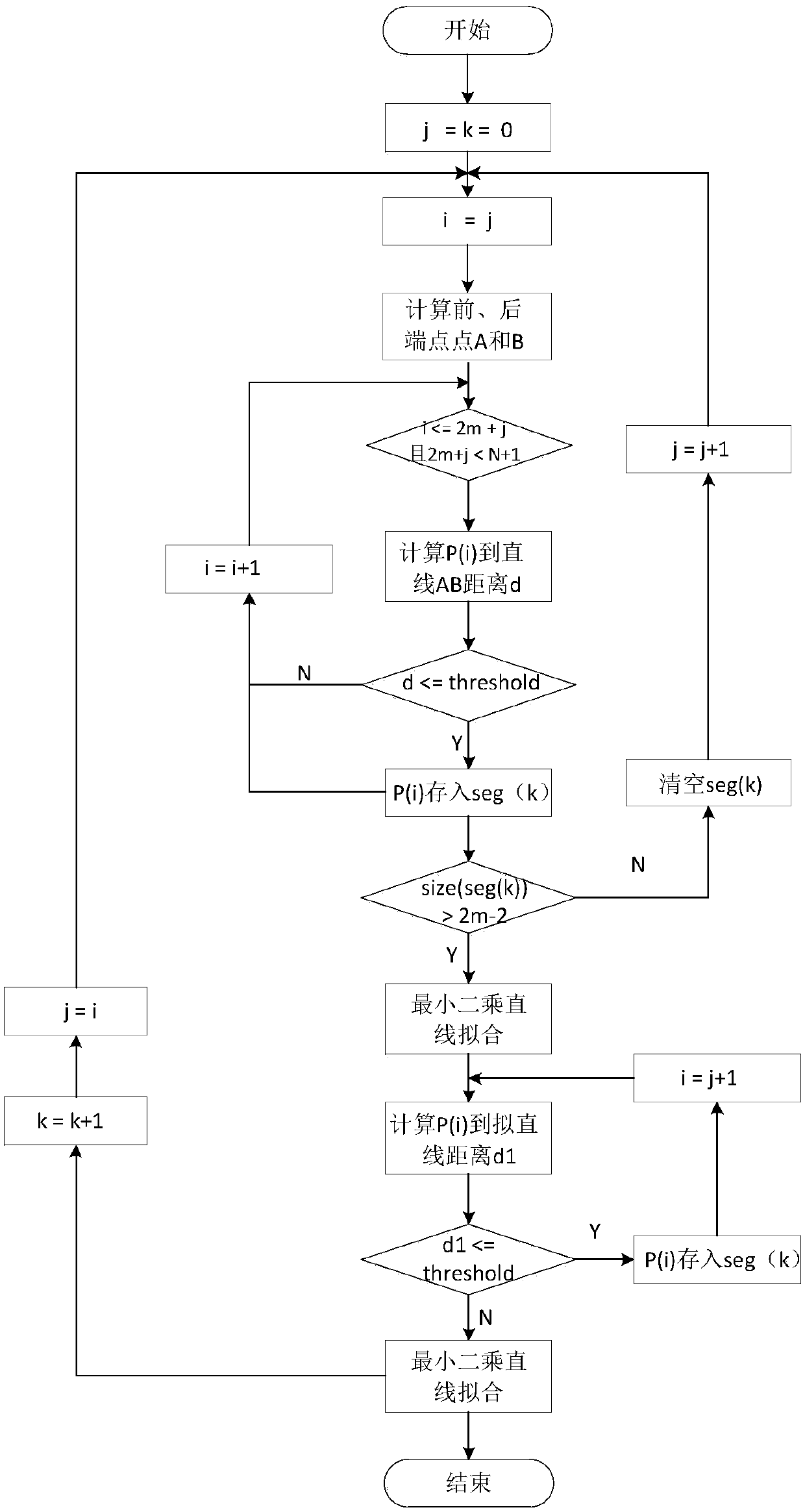

[0034] In order to further illustrate the technical scheme of the present invention, the following will be combined with the attached Figure 1-4 Describe this program in detail.

[0035] The automatic identification method applicable to substation narrow-scale pointer instruments of the present invention is carried out in the following manner:

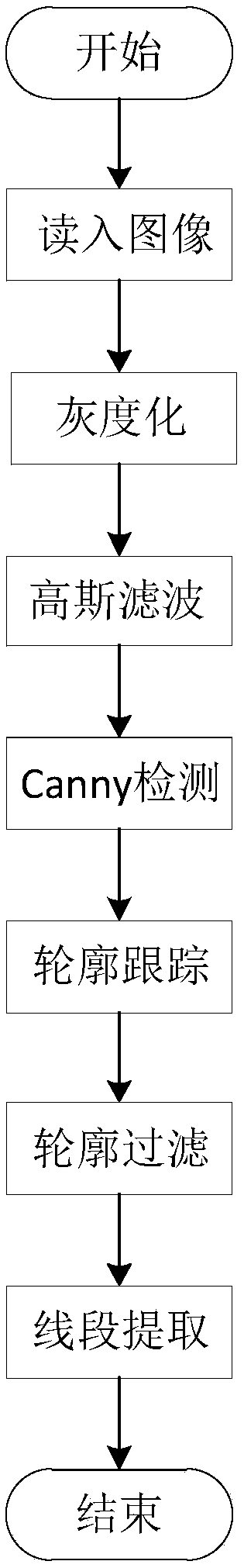

[0036] Step S1: Canny-based straight line detection, such as figure 2 Shown:

[0037] Step S11: First, read in the instrument image, after grayscale processing, use a 5x5 Gaussian convolution kernel for smoothing; then use the Canny algorithm to detect the edge of the instrument image, and use the eight-field contour tracking algorithm to obtain continuous single pixel edge contour;

[0038] Step S12: Use the length information of the single-pixel edge contour to perform contour filtering, that is, filter out the single-pixel edge contours whose length is less than 2m (the value range of m is [3,5]);

[0039] Step S13: if image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com