Strain gauge based side slipping detection method and device

A detection device and strain gauge technology, which can be applied to measurement devices, vehicle testing, and machine/structural component testing. Small size, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings of the description.

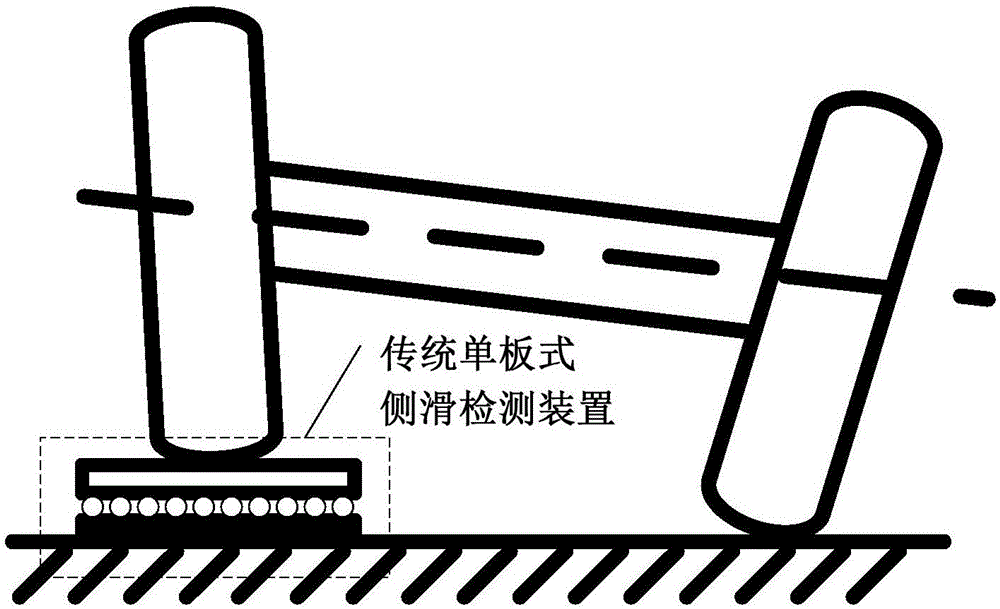

[0028] Such as figure 1 As shown, the existing single-plate side-sliding device has a height of about 10 cm, and often requires the cooperation of a transition plate, and the complete set of devices is mainly composed of steel plates, so the weight and portability will be greatly reduced. Adding the test board on the tire on one side will also cause a large inclination of the axis where the overall steering wheel is located, so that the gravity will generate a component force in the lateral direction, which will eventually affect the measurement results and make the measured data repeatability poor. .

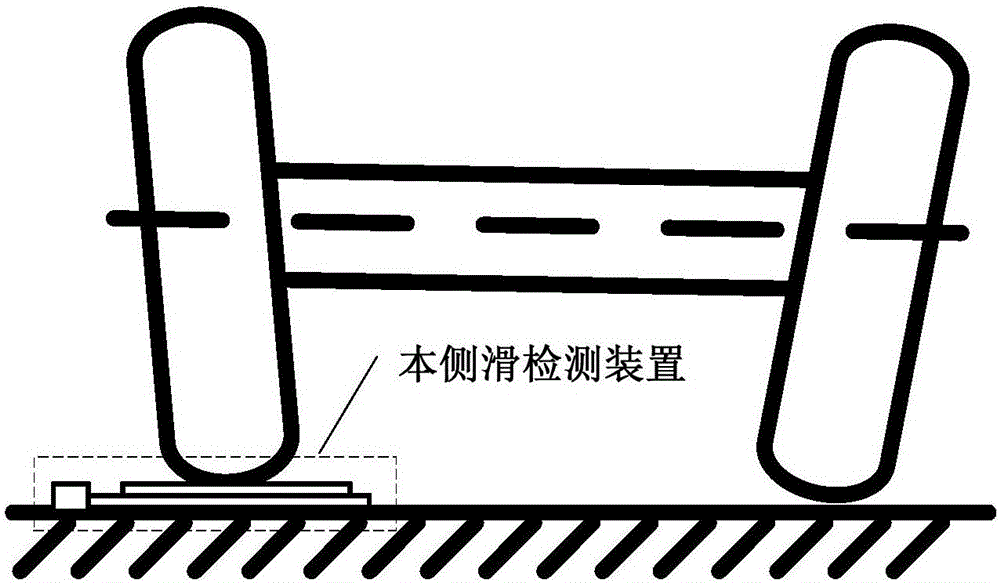

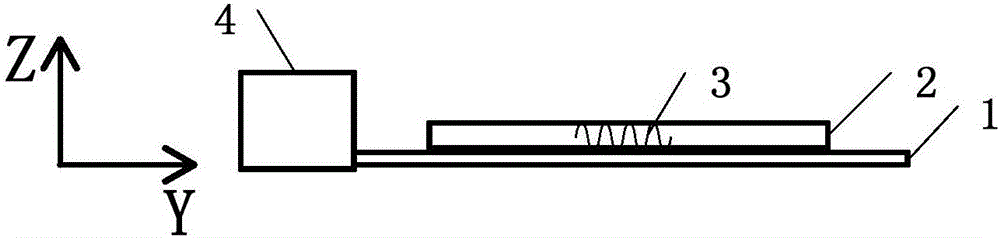

[0029] Such as figure 2 Shown, be the structure schematic diagram of the present invention; Because the induction part total thickness of device only has 5mm (the first layer is the elastic induction blanket that is used for sensing, and thickness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com