Copper bar structure used for power battery connection

A power battery and connecting part technology, which is applied in the direction of batteries, structural parts, battery pack parts, etc., can solve the problems of high cost, complicated nickel plating process, and environmental pollution, and achieve the effect of ensuring performance and avoiding electrochemical corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] Examples: The following specific examples illustrate the embodiments of the present invention, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

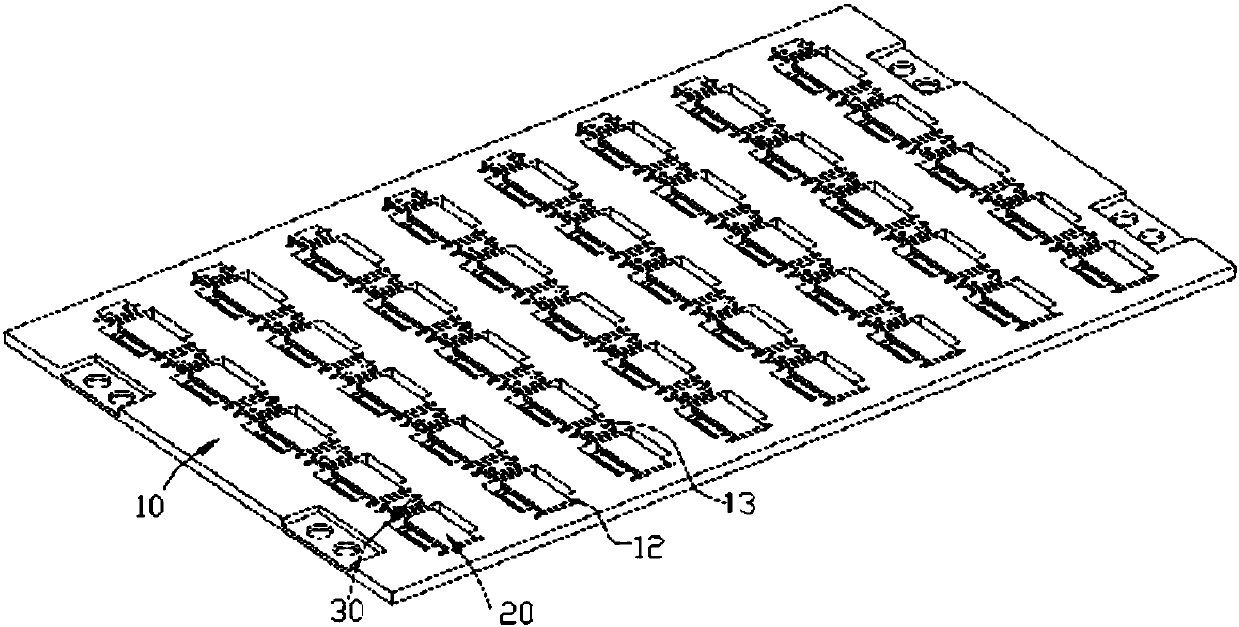

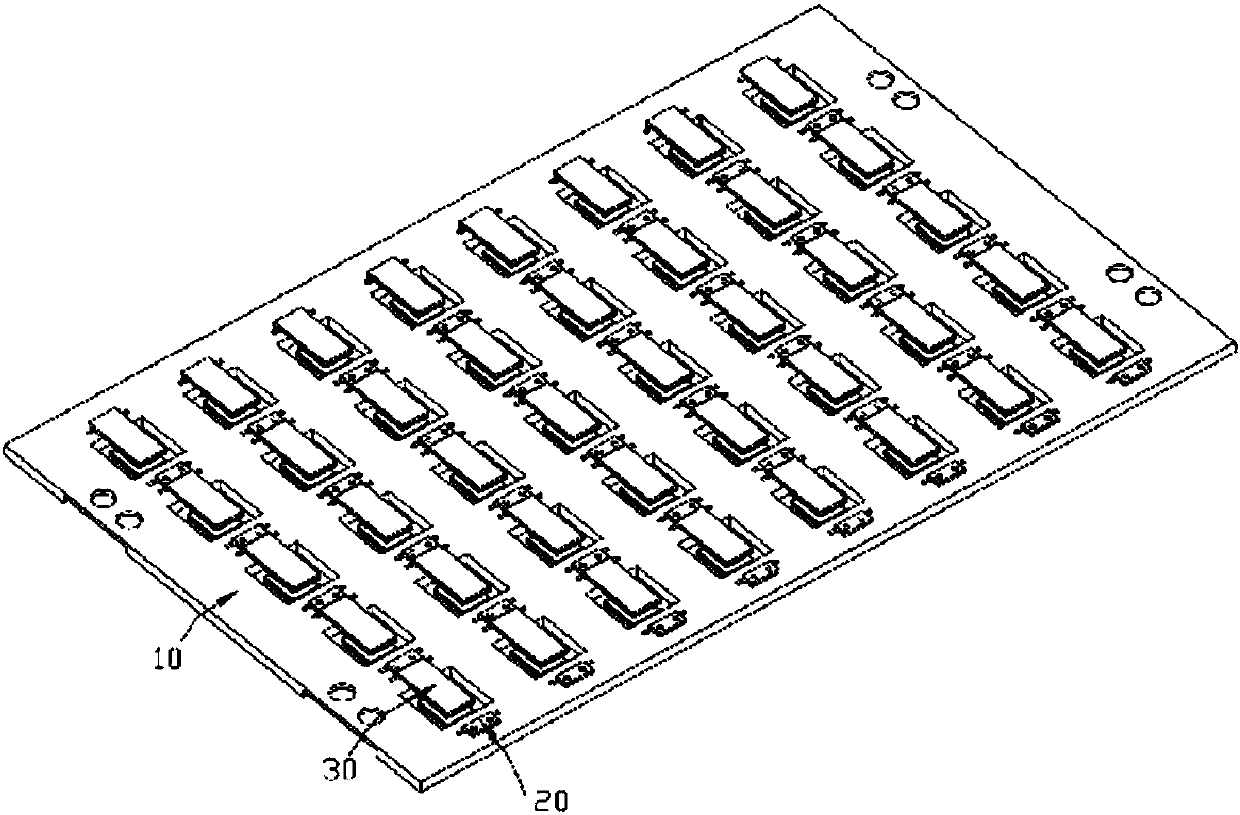

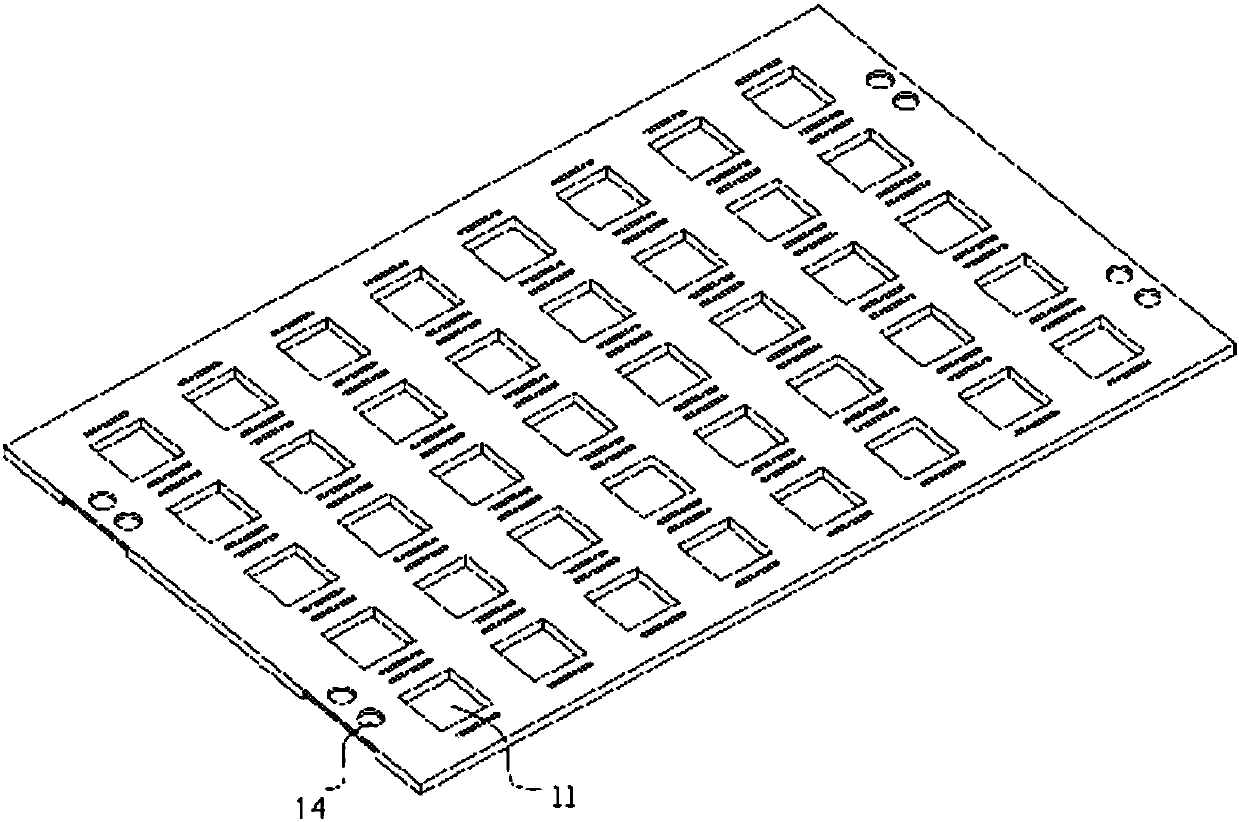

[0021] See Figure 1 to Figure 3 As shown, a copper bar structure for power battery connection includes: a copper substrate 10 with a plurality of accommodating holes 11, a plurality of small copper sheets 20 arranged on the first end surface of the copper substrate 10, Several small aluminum sheets 30 on the second end surface of the copper substrate 10, wherein the first end surface and the second end surface are two opposite large end surfaces on the copper substrate 10, and the small copper The sheet 20, the small aluminum sheet 30 and the accommodating hole 11 are arranged in one-to-one correspondence, see figure 1 As shown, two sides of each accommodating hole 11 are symmetrically provided with a first elongated sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com