Transverse jade cutting machine

A cutting machine and jade technology, applied in stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of low cutting efficiency, poor cutting stability, large size and weight of jade, and achieve improved processing efficiency and good stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

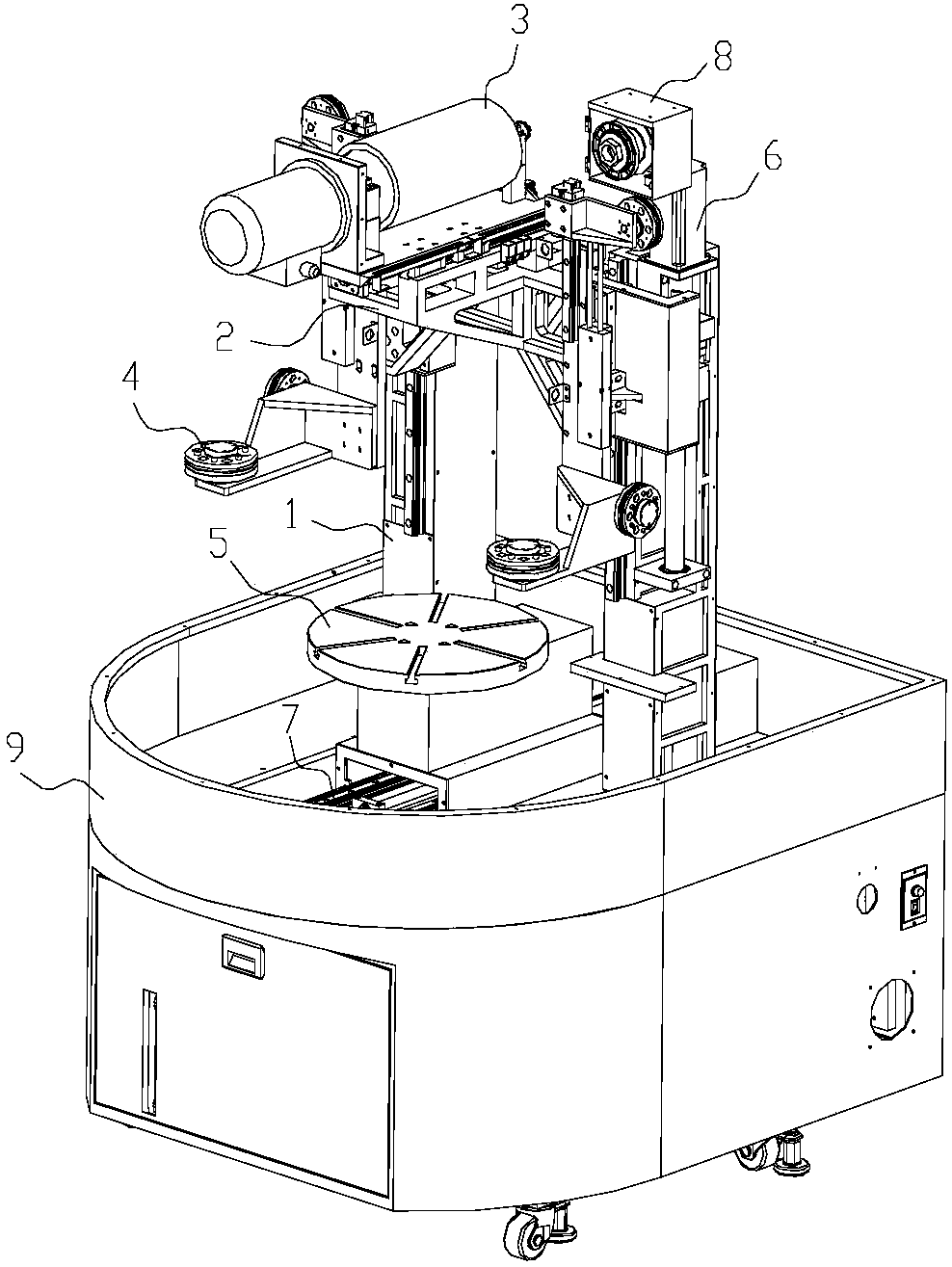

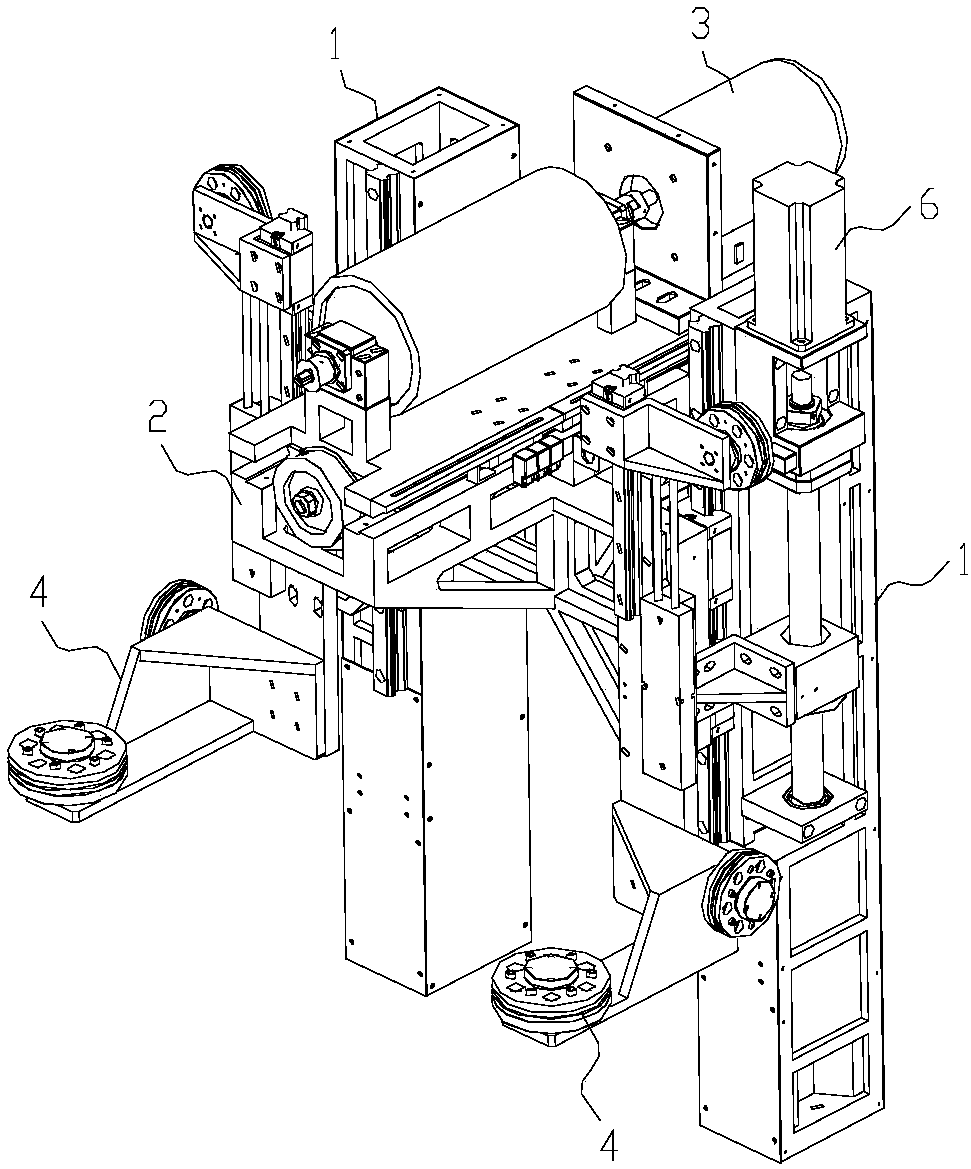

[0028] Such as Figure 1-8 As shown, a horizontal jade cutting machine includes two vertical arms 1, a bracket 2 slidably installed between the two vertical arms, an automatic retracting and unwinding mechanism 3 fixed on the bracket, and a cutting machine fixed on the bracket for changing cutting. The cutting wire guide mechanism 4 in the winding direction of the wire, the clamping disc 5 for fixing the jade set between the two vertical arms, and the front and rear parts for driving the clamping disc to move forward or backward are set under the clamping disc. Mobile mechanism 6;

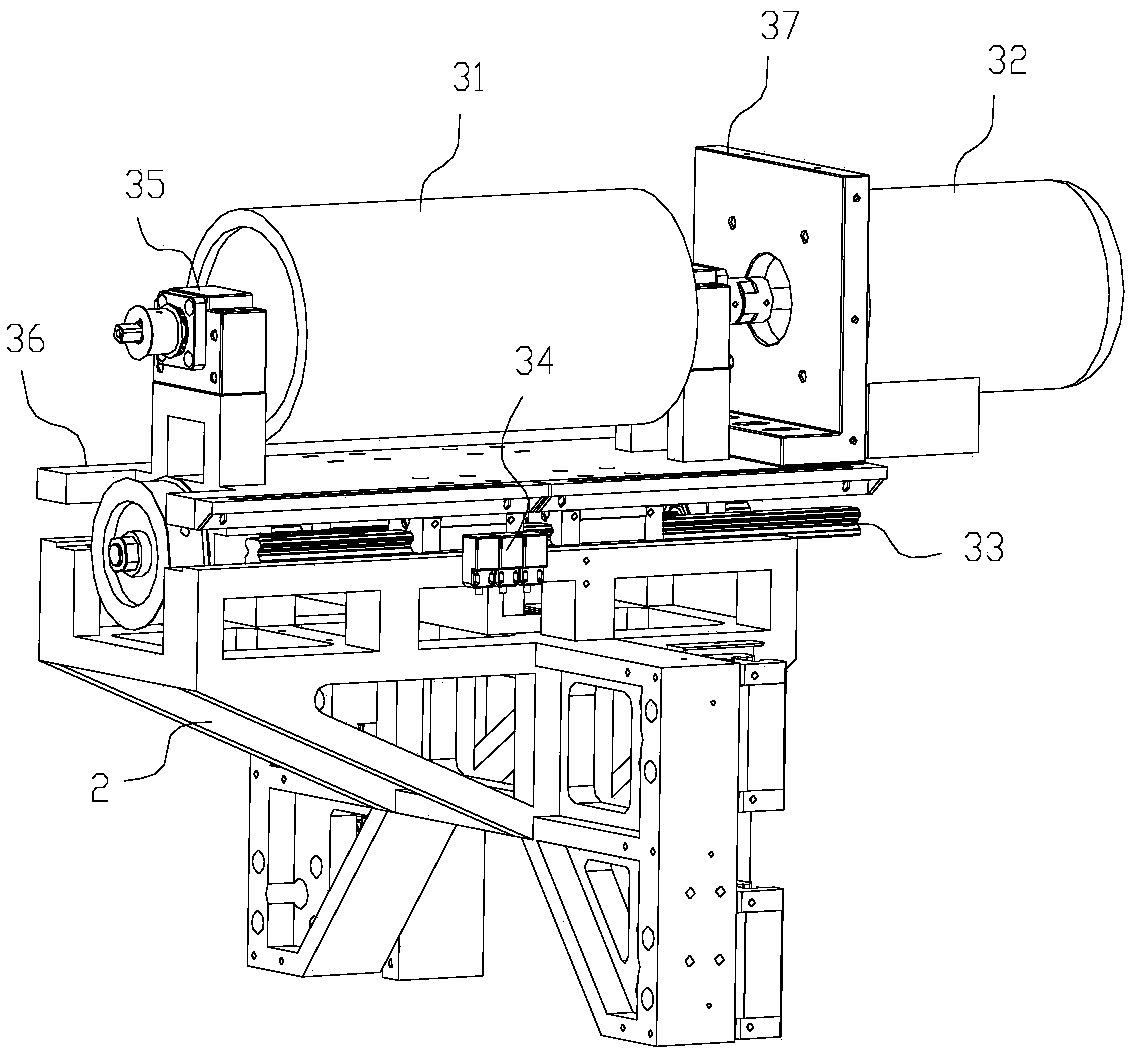

[0029] The automatic take-up and pay-off mechanism 3 includes a bobbin 31 for retracting and unwinding the cutting wire; It is horizontally arranged above the chucking disk; the chucking disk can be slidably installed on the forward and backward moving mechanism.

[0030]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com