Label cutting machine

A label cutting machine and cutting technology, which is applied in the direction of winding strips, sending objects, thin material processing, etc., to achieve the effect of improving productivity and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Describe its implementation details below in conjunction with accompanying drawing:

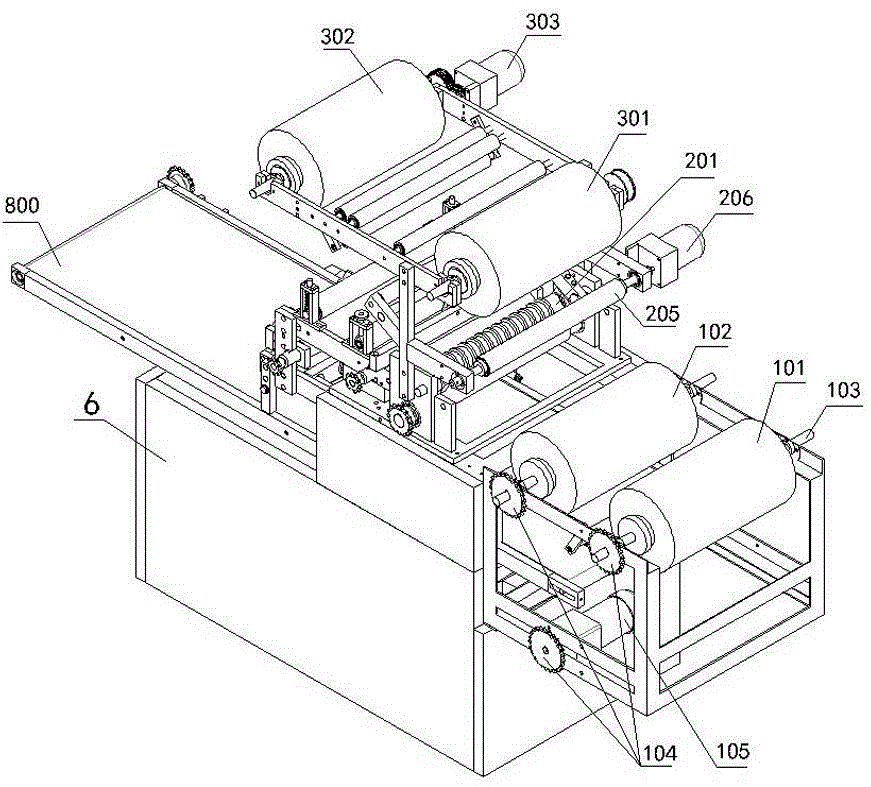

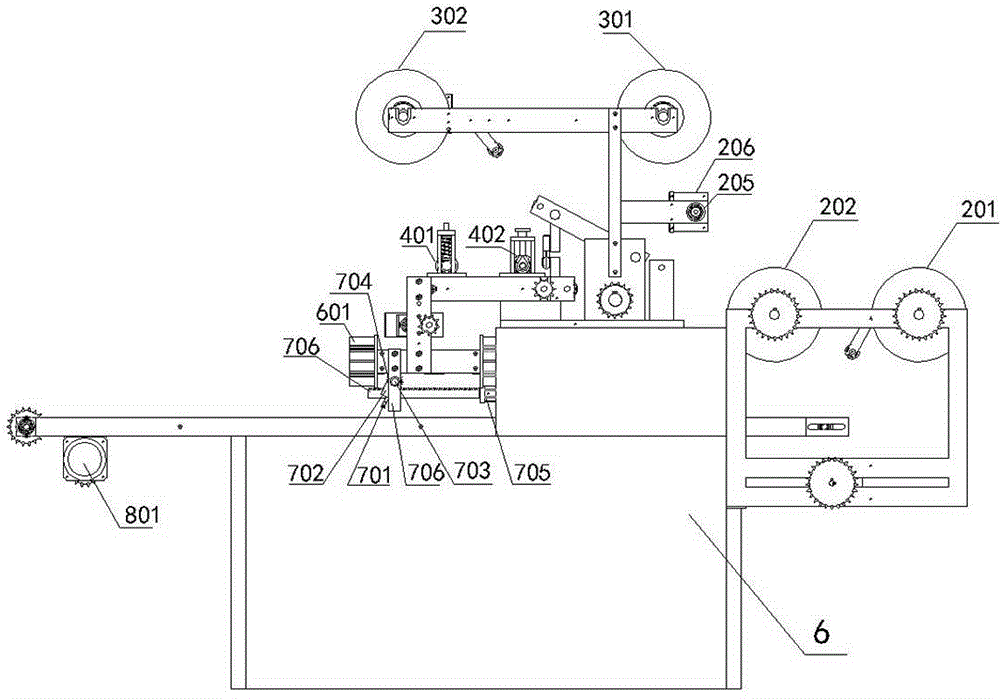

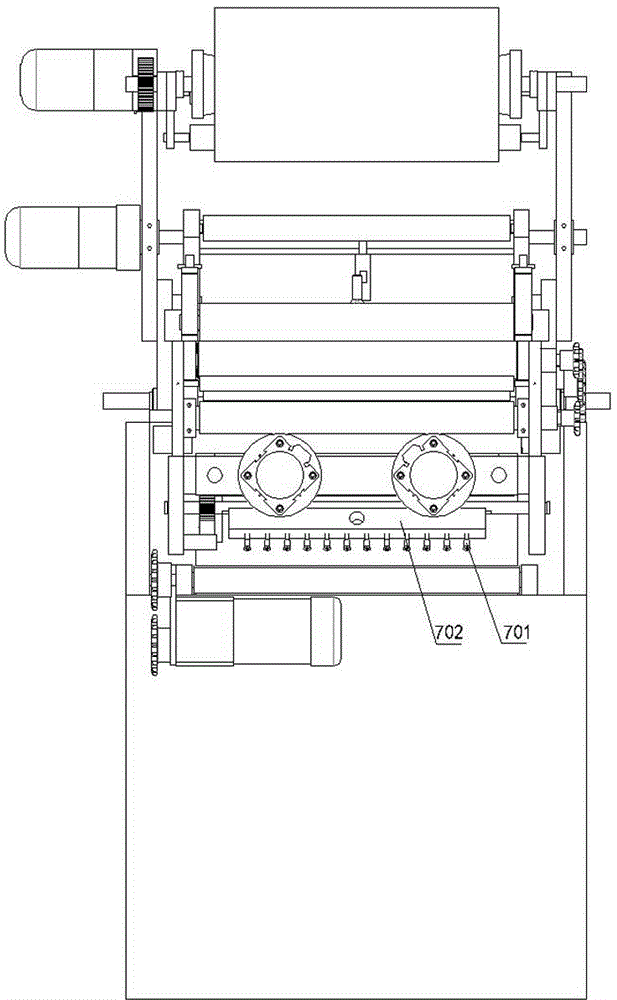

[0019] like figure 1 and Image 6 As shown, the label cutting machine includes a frame 6, and the right side of the frame 6 is provided with a feeding mechanism 100, and the feeding mechanism 100 includes a feeding roller 102 and a film collecting roller 101 located at the feeding roller 102 rear, and the feeding roller 102 It is used to place the raw rubber material 1. Since this material has strong viscosity, in order to prevent the long strips of raw rubber material 1 wound into rolls from sticking together, a layer of film 2 is pasted on the surface of the material. The film roller 101 is just used for reclaiming this film 2, and the roller shaft 103 on the side of the feeding roller 102 and the film receiving roller 101 is provided with a gear 104, and the gear 104 on the two gears 104 and the lower feeding motor 105 passes through a toothed chain Realize synchronous rotation. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com