Yellow-green mechanoluminescence ceramic material and preparation method thereof

A ceramic material and luminescent technology, applied in the field of ceramics, can solve problems such as weak luminous intensity and difficulty in low-light detection, achieve high compressive strength and enhance the effect of luminescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

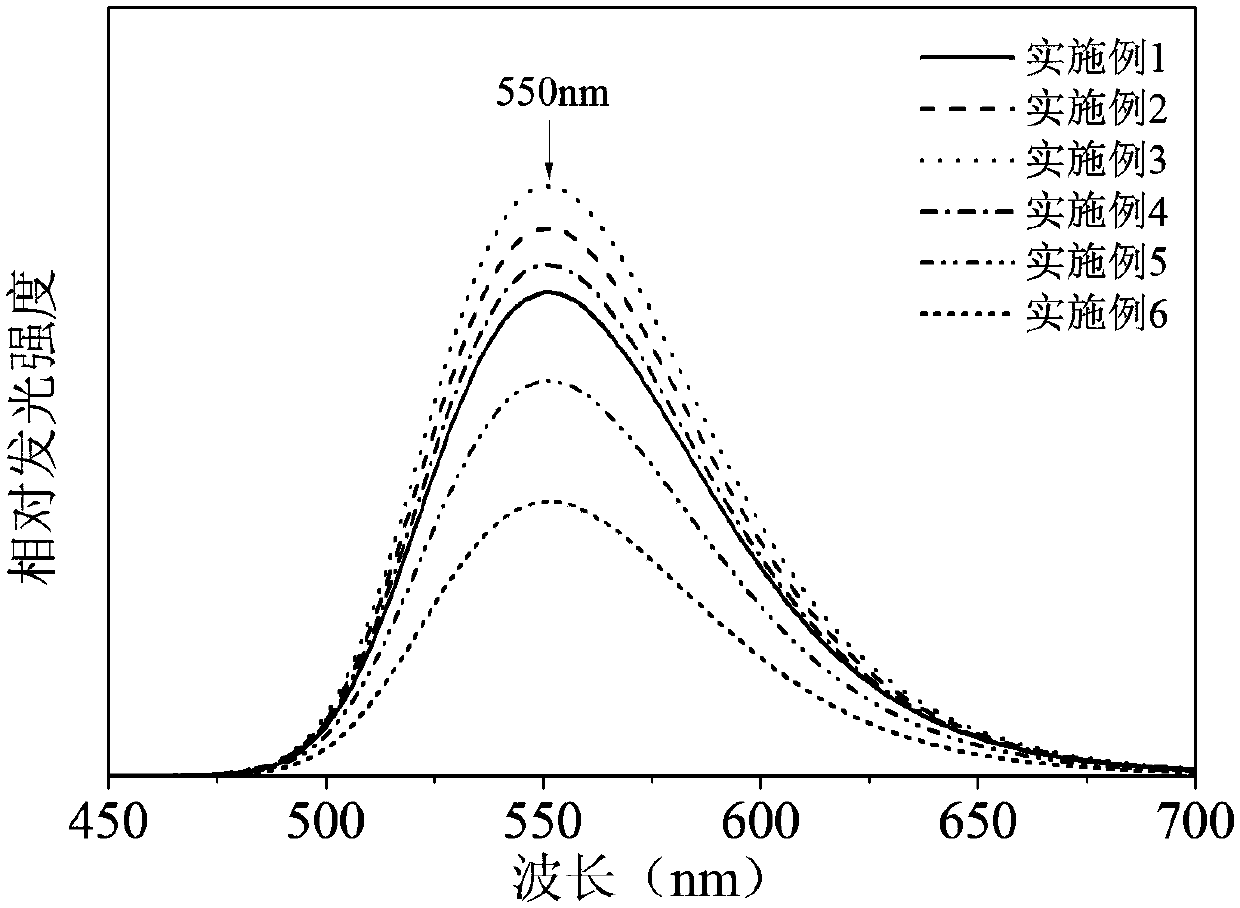

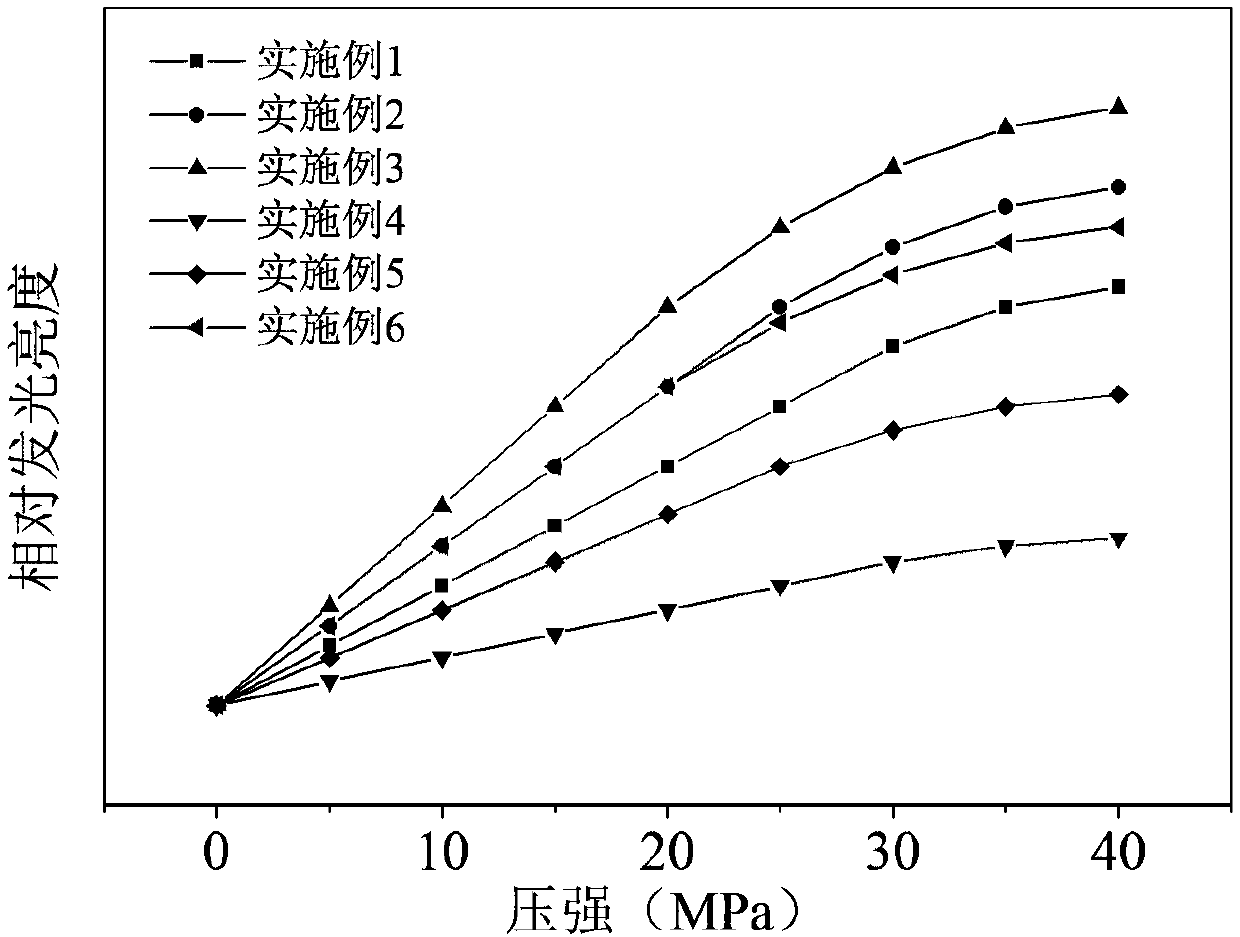

[0125] A yellow-green mechanoluminescent ceramic material with a chemical composition of Sr 1.98 Si 7 o 4 N 8 : 0.01Eu 2+ , 0.01Gd 3+ .

[0126] With high purity SrCO 3 , SiO 2 、Si 3 N 4 、Eu 2 o 3 and Gd 2 o 3 As a raw material, according to the chemical composition general formula Sr 1.98 Si 7 o 4 N 8 : 0.01Eu 2+ , 0.01Gd 3+ The ratio of each element in the formula is accurately weighed raw materials; agate balls are used as grinding balls, absolute ethanol is used as a ball milling medium, agate balls, absolute ethanol and raw materials are put into a ball milling tank at the same time, and ball milling is carried out on a planetary ball mill. feed for 10 hours to form a slurry-like mixture, the mass ratio of the absolute ethanol to the raw material is 2:3; the obtained slurry-like mixture is placed in an oven, and dried for 4 hours at 80 ° C, and then The raw materials obtained after drying are passed through a 200-mesh sieve to obtain uniformly mixed raw...

Embodiment 2

[0128] A yellow-green mechanoluminescent ceramic material with a chemical composition of Sr 1.96 Si 7 o 4 N 8 : 0.02Eu 2+ , 0.02Lu 3+ .

[0129] With high purity SrCO 3 , SiO 2 、Si 3 N 4 、Eu 2 o 3 and Lu 2 o 3 As a raw material, according to the chemical composition general formula Sr 1.96 Si 7 o 4 N 8 : 0.02Eu 2+ , 0.02Lu 3+ The ratio of each element in the formula is accurately weighed raw materials; agate balls are used as grinding balls, absolute ethanol is used as a ball milling medium, agate balls, absolute ethanol and raw materials are put into a ball milling tank at the same time, and ball milling is carried out on a planetary ball mill. feed for 5 hours to form a slurry-like mixture, the mass ratio of the absolute ethanol to the raw material is 2:3; the obtained slurry-like mixture is placed in an oven, and dried for 6 hours at 80 ° C, and then The raw materials obtained after drying are passed through a 200-mesh sieve to obtain uniformly mixed raw ...

Embodiment 3

[0131] A yellow-green mechanoluminescent ceramic material with a chemical composition of Sr 1.92 Si 7 o 4 N 8 : 0.04Eu 2+ , 0.02Gd 3+ ,0.02Lu 3+ .

[0132] With high purity SrCO 3 , SiO 2 、Si 3 N 4 、Eu 2 o 3 、Gd 2 o 3 and Lu 2 o 3 As a raw material, according to the chemical composition general formula Sr 1.92 Si 7 o 4 N 8 : 0.04Eu 2+ , 0.02Gd 3+ , 0.02Lu 3+ The ratio of each element in the formula is accurately weighed raw materials; agate balls are used as grinding balls, absolute ethanol is used as a ball milling medium, agate balls, absolute ethanol and raw materials are put into a ball milling tank at the same time, and ball milling is carried out on a planetary ball mill. Feed for 15 hours to form a slurry mixture, the mass ratio of the absolute ethanol to the raw material is 2:3; the obtained slurry mixture is placed in an oven, and dried for 5 hours at 80°C, and then The raw materials obtained after drying are passed through a 200-mesh sieve to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com