A kind of diamond/aluminum composite material and high-efficiency preparation method thereof

An aluminum composite material and diamond technology, which is applied in the field of diamond/aluminum composite material and its preparation, can solve the problems of insufficient interface reaction between diamond and aluminum, weak interface bonding, low thermal conductivity, etc., so as to meet the forming accuracy and improve the interface The effect of bonding strength and improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

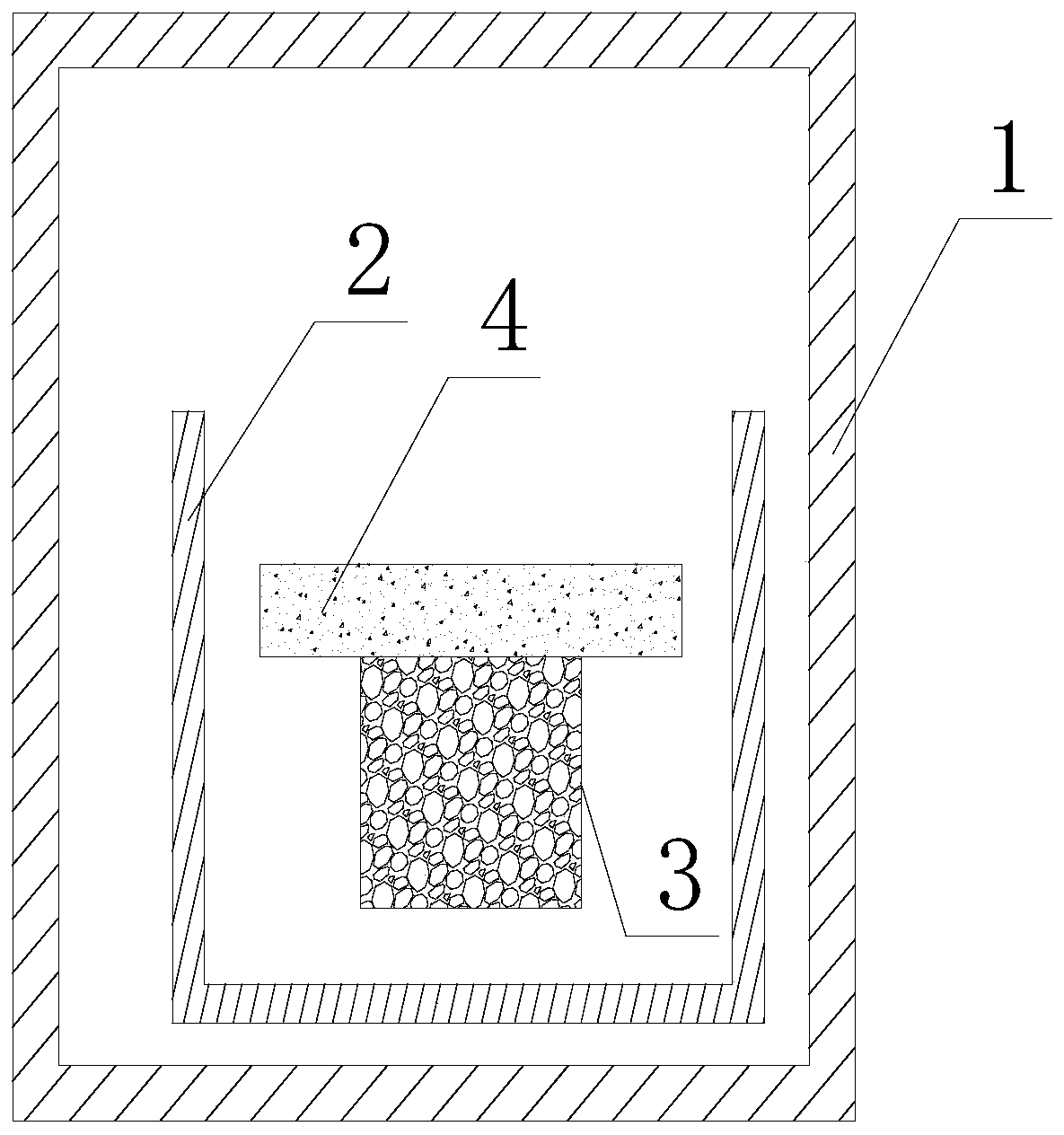

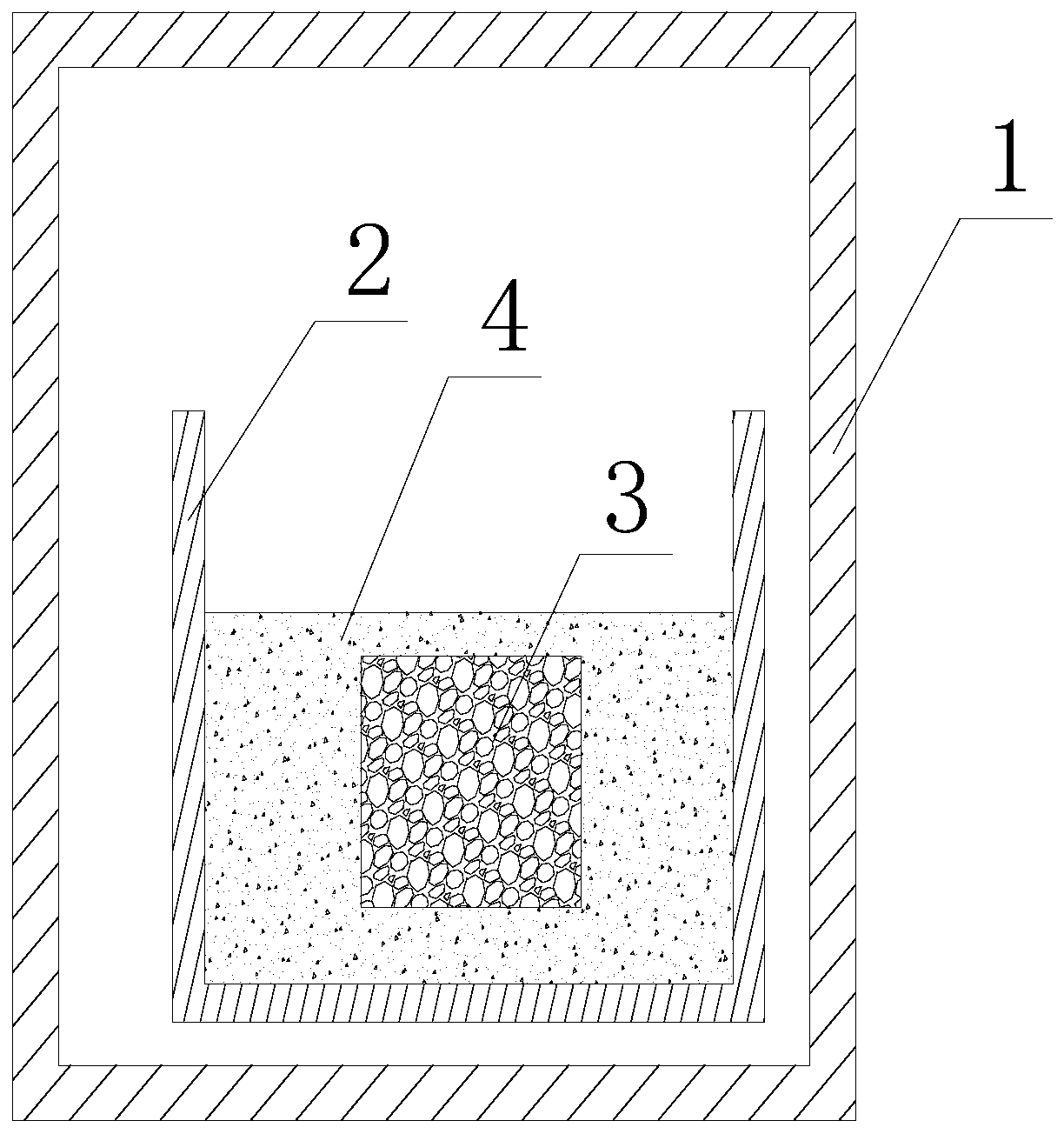

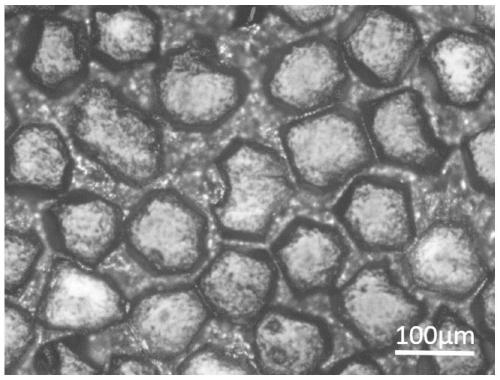

[0043] Embodiment 1: In this embodiment, a diamond / aluminum composite material is composed of aluminum metal and diamond powder with a coating layer, and the aluminum metal is filled in the gap of the diamond powder with a coating layer;

[0044] The aluminum metal is pure aluminum or aluminum alloy;

[0045] The coating layer of the diamond powder with coating layer is one layer or more than two layers;

[0046] The material of the coating layer is Ti, Cr, W, Mo or Zr;

[0047] The volume fraction of diamond powder in the diamond / aluminum composite material is 50%-60%.

[0048] This embodiment has the following beneficial effects:

[0049] The compactness of the diamond / aluminum composite material in this embodiment reaches more than 99.8%, which solves the problem of low density of the diamond / aluminum composite material; the coating layer on the surface of the single crystal diamond powder in this embodiment improves the bond between diamond powder and aluminum Wettabili...

specific Embodiment approach 2

[0050] Embodiment 2: This embodiment is different from Embodiment 1 in that: the thickness of the coating layer is 30-500 nm. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0051] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that: the particle size of the diamond powder is 10-300 μm. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com