Screw and production process thereof

A production process and screw technology, applied in the direction of screws, threaded fasteners, connecting components, etc., can solve the problems of wasting time, inconvenience, and difficult to fit nut parts all at once, and achieve high machining accuracy and stable locking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

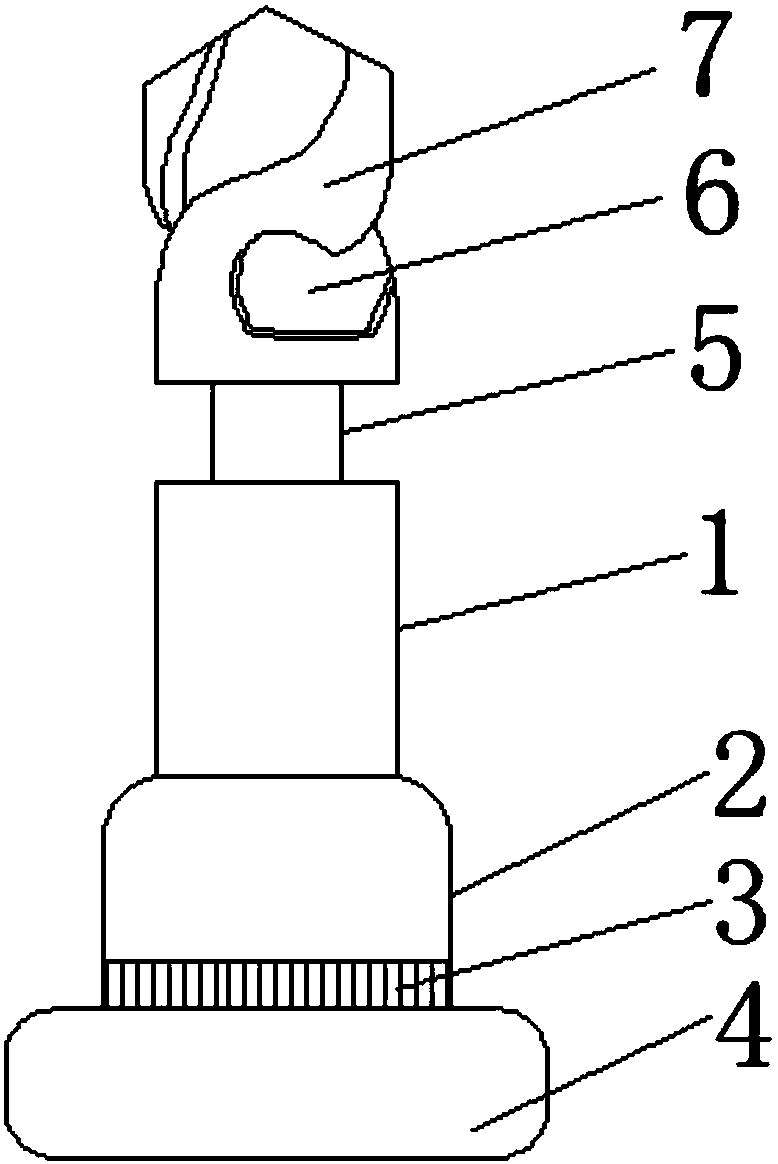

[0021] A screw, comprising a first rod body 1, one end of the first rod body 1 is connected to a second rod body 2, a twist plate 4 is provided at one end of the second rod body 2, and a groove is opened at the upper end of the first rod body 1 5. The upper end of the channel 5 is provided with a screw point 7, and two quick-lock guide slide grooves 6 are symmetrically opened on the screw point 7.

[0022] Specifically, anti-slip lines 3 are provided at the lower end of the second rod body 2 and at the joint with the twist plate 4 .

[0023] Specifically, the rotation curve angle of the quick lock guide chute 6 is 180 degrees.

[0024] The present invention also provides a screw production process, comprising the steps of:

[0025] S1. Cut the wire rod into the required length, send the wire rod of this length into the first mold, and punch out the initial shape of the first rod body 1, the second rod body 2, the twist plate 4 and the screw tip 7 by cold heading;

[0026] S2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com