Two-point correction method for uncooled infrared detector

An uncooled infrared and detector technology, applied in radiation pyrometry, instruments, measuring devices, etc., can solve problems such as large space noise and achieve the effect of improving imaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

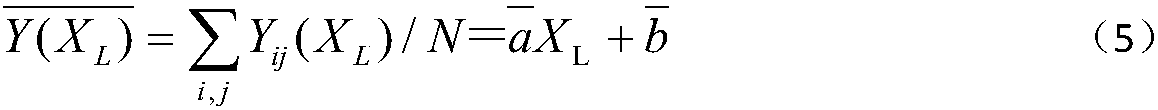

[0041] The specific steps of a two-point calibration method for an uncooled infrared detector are:

[0042] The first step is to build a two-point calibration system for uncooled infrared detectors

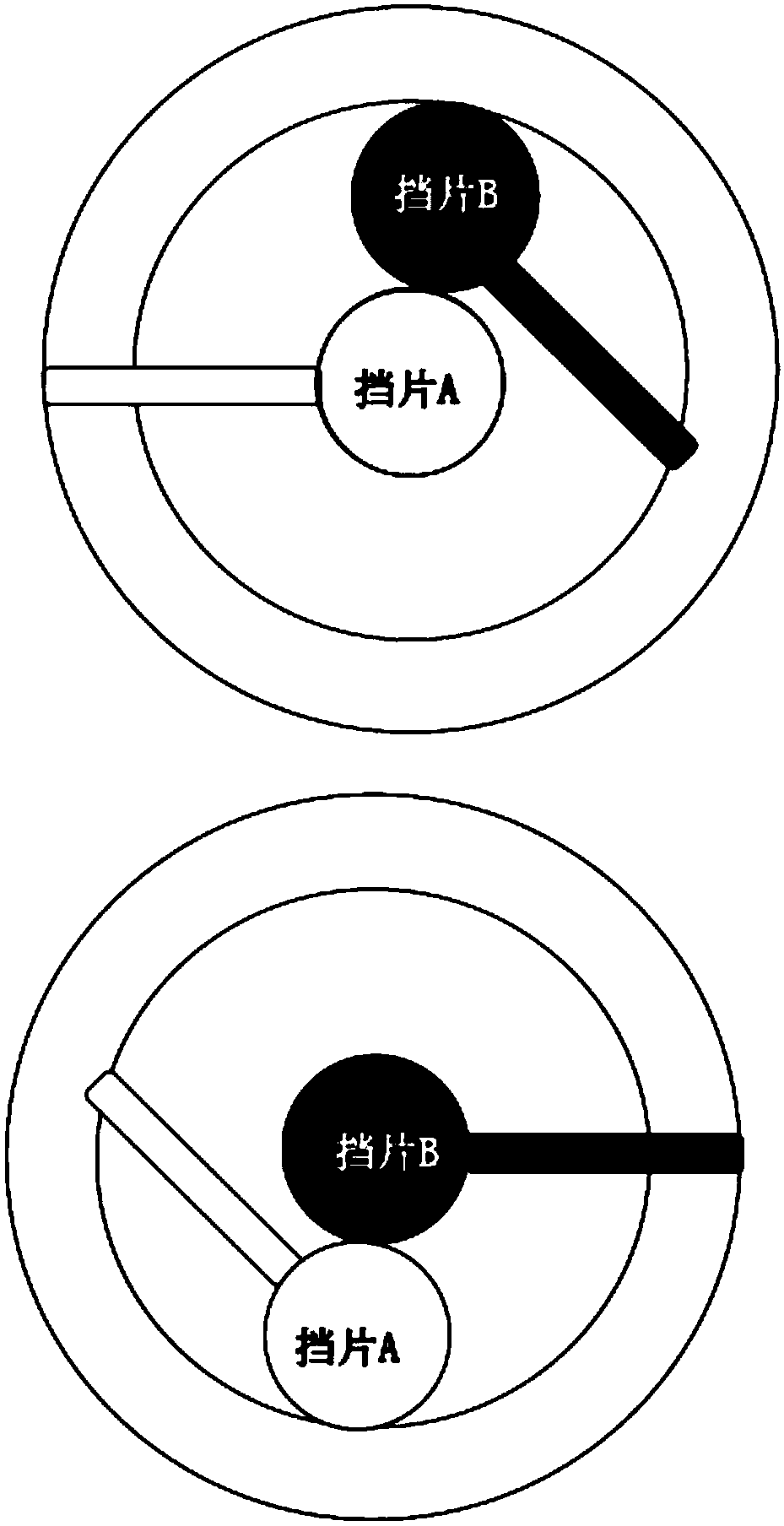

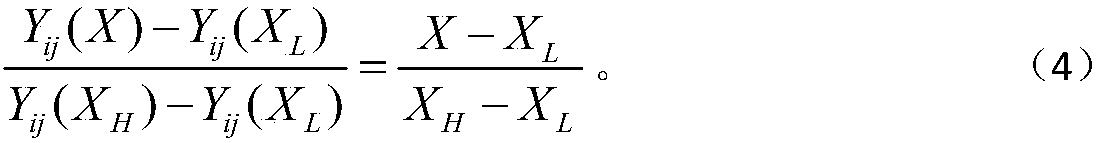

[0043] The two-point calibration system of the uncooled infrared detector includes: block A, block B, detector and output circuit module, block control module and FPGA data processing module.

[0044] The function of the detector and the output circuit module is to collect analog signals and convert them into digital signals.

[0045] The function of the baffle control module is to control the orderly appearance of baffles A and B in front of the detector glass window to obtain different radiation fluxes.

[0046] The function of the FPGA data processing module is to use the collected data to realize two-point non-uniform correction.

[0047] The second step: detector and output circuit module for signal acquisition and conversion

[0048] Collect the analog signal and convert ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com