Designing method of double-tube plate heat exchanger tube plate

A double-tube-sheet heat exchanger and design method technology, applied in the direction of heat exchanger shell, heat exchange equipment, lighting and heating equipment, etc., can solve problems such as potential safety hazards, waste of materials, insufficient strength of heat exchanger tube sheets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The main structure of the double-tube double-tubesheet heat exchanger includes two outer tubesheets and two inner tubesheets. Two ends of the inner heat exchange tube are respectively connected to two outer tube sheets, and two ends of the outer heat exchange tube are respectively connected to two inner tube sheets. There is a gap between the inner heat exchange tube and the outer heat exchange tube, and there is no constraint between the two.

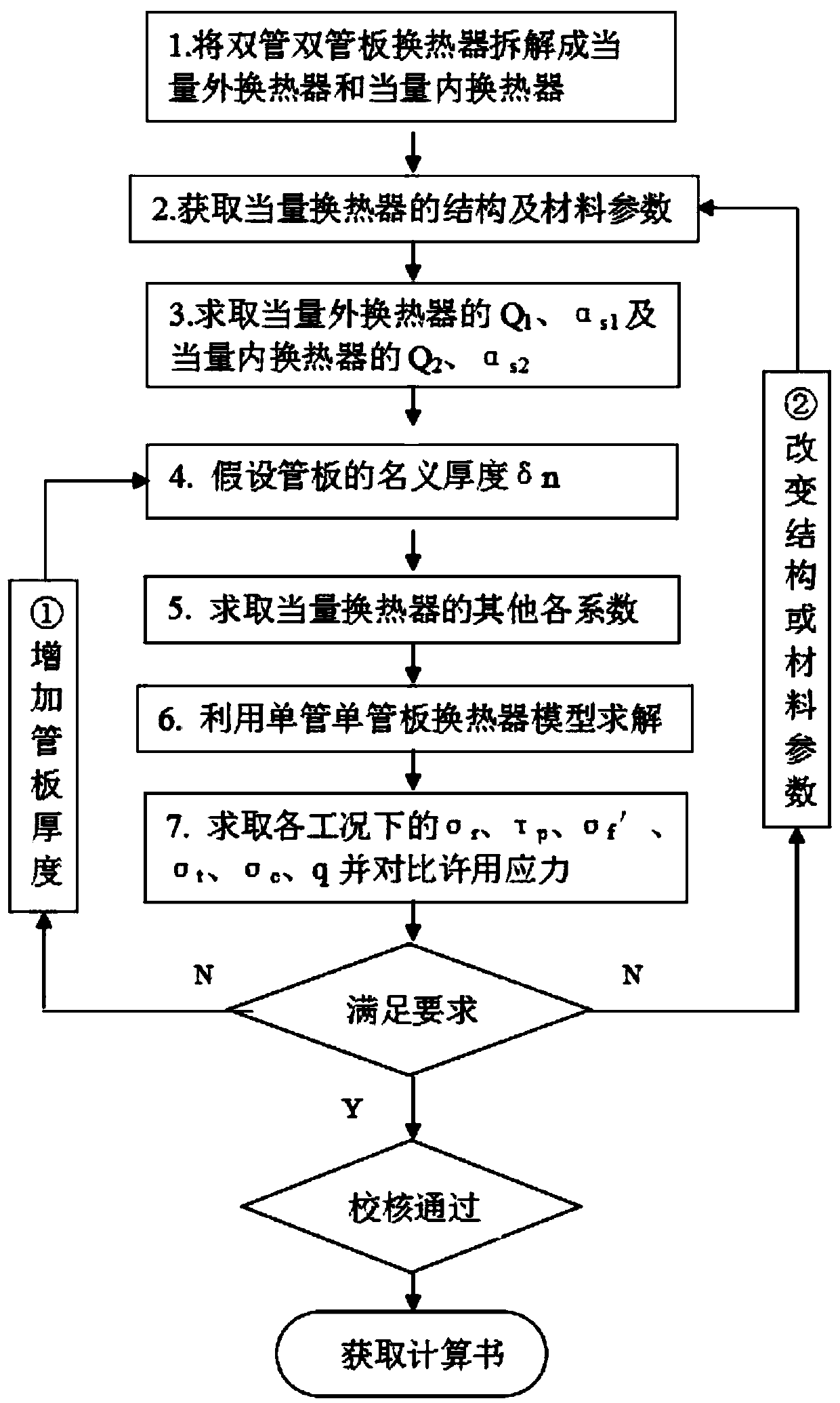

[0019] When calculating the tube sheet memory design of a double-tube double-tube-sheet heat exchanger, the heat exchanger should first be disassembled to obtain an equivalent external heat exchanger composed of an inner heat exchange tube and an outer tube sheet, and a Equivalent inner heat exchanger composed of outer heat exchange tubes and inner tube sheets. For the equivalent external heat exchanger, the cylinder is also constrained by the outer heat exchange tube and the inner tube sheet, and for the equivalent internal he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com