A method and application of selective adsorption of aroma components in high-temperature pyrolysis flue gas of tobacco

A technology of aromatizing components and high-temperature pyrolysis, applied in separation methods, applications, tobacco, etc., can solve the problems of unused new tobacco products, less separation of smoke components, etc., achieve good industrial application prospects, increase market acceptance, and process The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

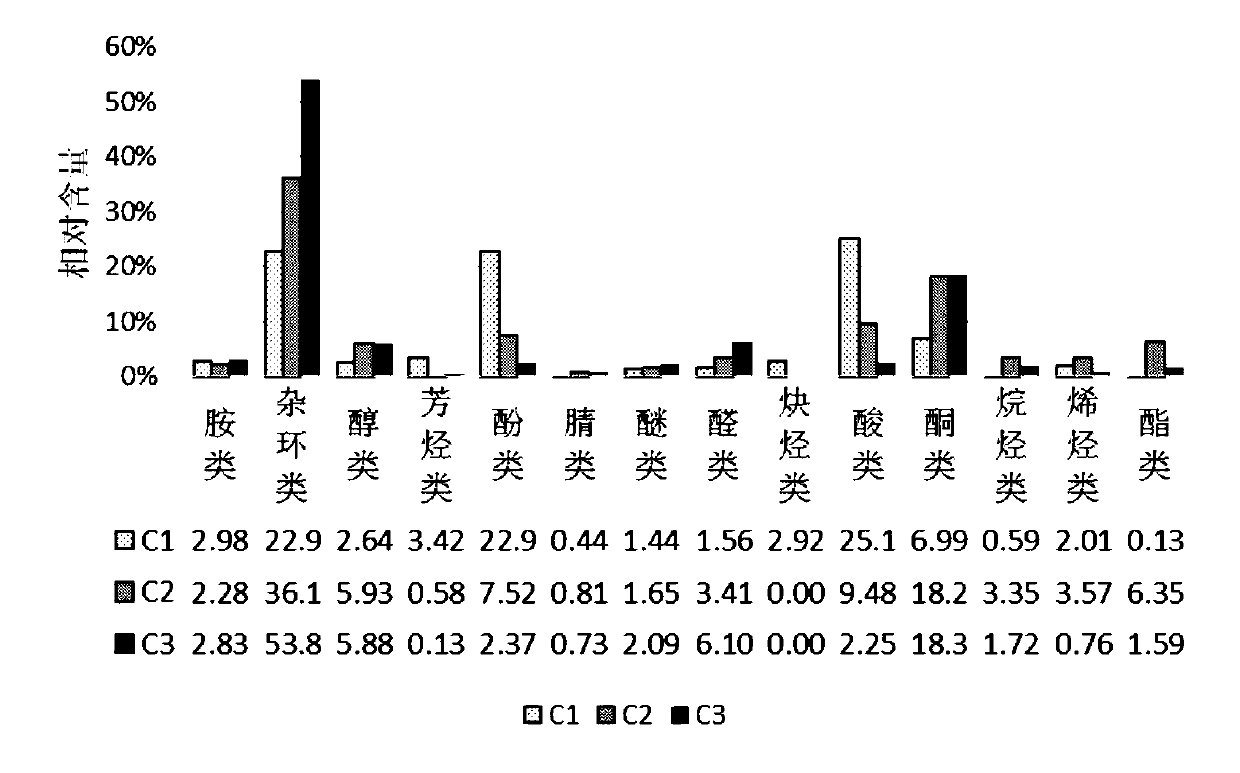

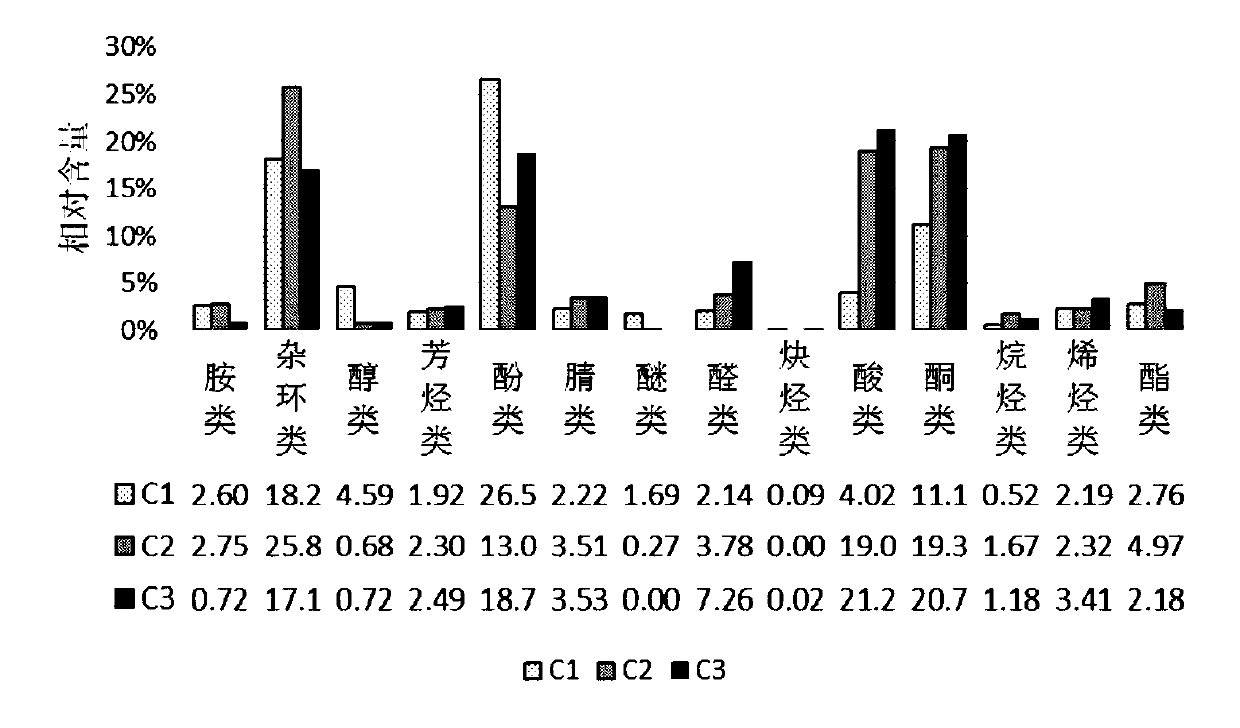

Embodiment 1

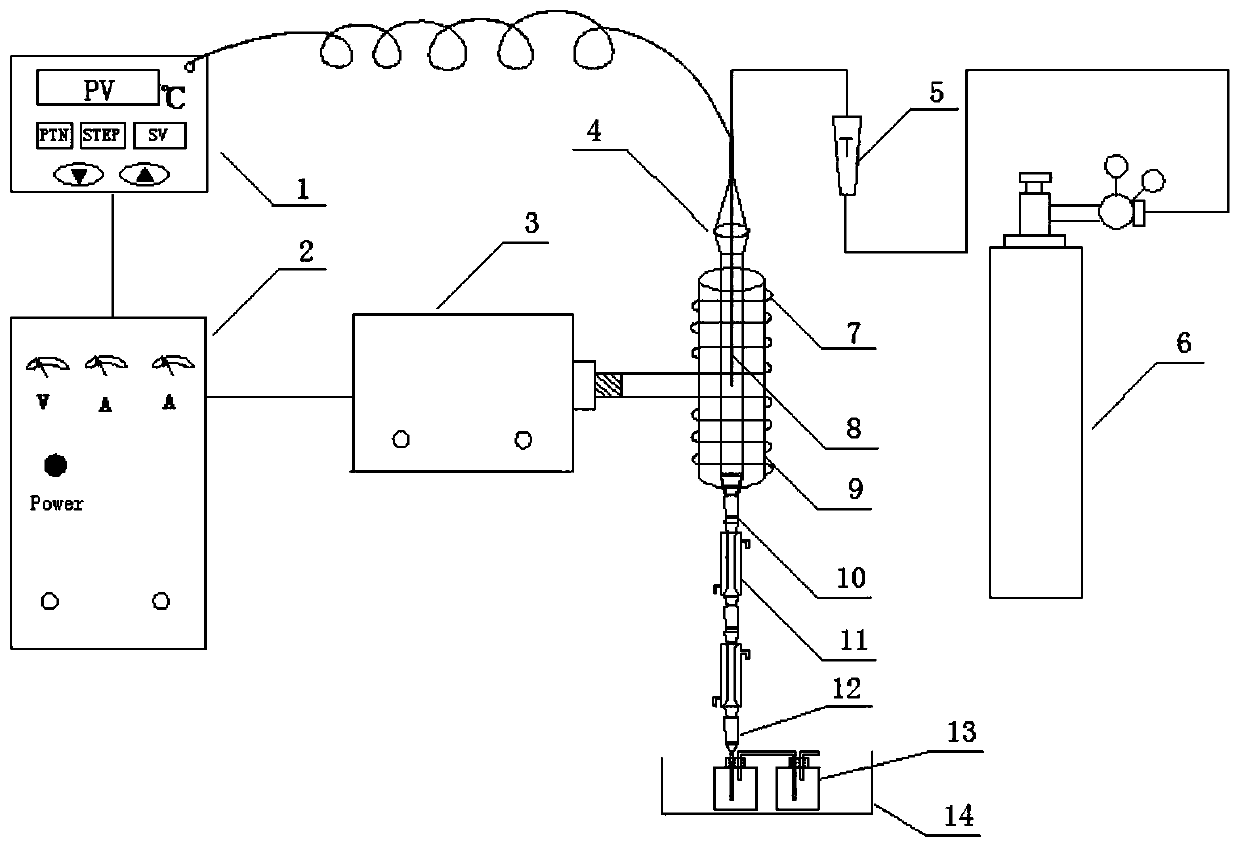

[0058] Weigh 10g of shredded tobacco and fill it into the body of quartz reaction tube 4, weigh 3 parts of 1g of alumina and add them to two straight sand core tubes 10 and sand core funnel 12 respectively, and measure 2 parts of 25ml absorption solution into the wide mouth In the bottle 13, add an amount of ice cubes and water in the ice bath 14, and insert a thermometer so as to observe its temperature. Apply vacuum silicone grease to the instrument interface. After the instrument is installed, turn on the condensed water of the all-solid induction heater 2, the transformer 3, the copper hollow coil 7 and the straight condenser tube 11, and turn on the switch of the high-pressure gas source 6 to provide a cracking atmosphere. Nitrogen, the gas flow rate is 50ml / min, then turn on the power switch of the intelligent regulator 1 and the all-solid induction heating device 2, and set the temperature rise program as follows: the initial temperature is 20°C, after 1.5min reaches 550...

Embodiment 2

[0060] Weigh 10g shredded tobacco and fill it into the body of the quartz reaction tube, weigh 3 parts of 1g ZSM-5 molecular sieve (silicon-aluminum ratio is 25) and add them to two straight sand core tubes and sand core funnel respectively, and measure 2 parts of 25ml Add the absorption solution into the jar, add appropriate amount of ice cubes and water into the ice bath, and insert a thermometer to observe its temperature. Apply vacuum silicone grease to the interface of the instrument. After the instrument is installed, turn on the condensed water of the all-solid induction heater, transformer, copper hollow coil and straight condenser tube, and turn on the high-pressure gas source switch to provide cracking atmosphere nitrogen. The gas flow rate is 50ml / min, then turn on the power switch of the intelligent regulator and the all-solid induction heater, and set the heating program as follows: the initial temperature is 20°C, after 1.5min it reaches 550°C, after 0.5min it rea...

Embodiment 3

[0062] Weigh 10g shredded tobacco and fill it into the quartz reaction tube body, weigh 3 parts of 1g ZSM-5 molecular sieve (silicon-aluminum ratio is 117) and add them to two straight sand core tubes and sand core funnel respectively, and measure 2 parts of 25ml Add the absorption solution into the jar, add appropriate amount of ice cubes and water into the ice bath, and insert a thermometer to observe its temperature. Apply vacuum silicone grease to the interface of the instrument. After the instrument is installed, turn on the condensed water of the all-solid induction heater, transformer, copper hollow coil and straight condenser tube, and turn on the high-pressure gas source switch to provide cracking atmosphere nitrogen. The gas flow rate is 50ml / min, then turn on the power switch of the intelligent regulator and the all-solid induction heater, and set the heating program as follows: the initial temperature is 20°C, after 1.5min it reaches 550°C, after 0.5min it reaches 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com