Determination method for incipient cavitation number of flattop pore plate

A method for determining the cavitation number, which is applied in the field of determining the primary cavitation number of flat-head orifice plates, can solve the quantitative relationship between the primary cavitation number and related body shape elements and hydraulic elements, and is not suitable for direct application in actual engineering. Poor performance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

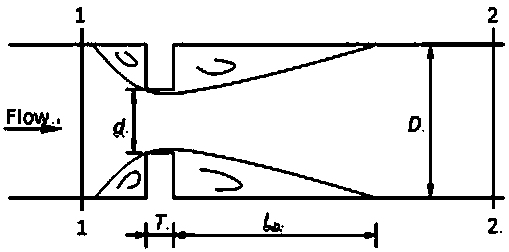

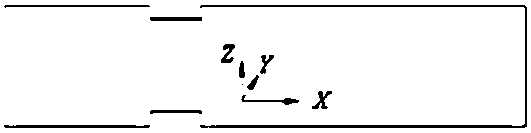

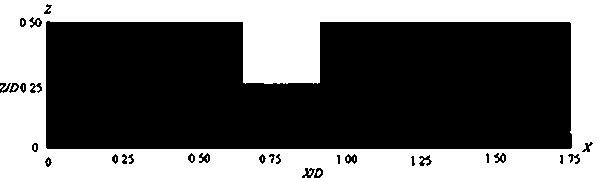

[0045] Such as Figure 1 to Figure 7 As shown in , a method for determining the primary cavitation number of a flat-head orifice plate adopts the following steps:

[0046] Step 1. Determine the number σ that affects the primary cavitation i factors, including the pipe flow Reynolds number Re, the ratio β of the orifice diameter d to the spillway diameter D, the ratio α of the orifice thickness T to the spillway diameter D;

[0047] Step 2. Based on the RNG k-ε model, a numerical simulation model of water flow through the flat-head orifice is established;

[0048] Step 3. Determine the primary cavitation number σ based on the RNG k-ε model i calculation method;

[0049] Step 4: Analyze and fit the numerical simulation results to determine the primary cavitation number σ i and affect the nascent cavitation number σ i An empirical expression...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com