Power-supply-station tool-warehouse unattended intelligent management system and method

A technology for power supply work and management system, applied in the field of information management, can solve problems such as low work efficiency, achieve the effect of improving operation efficiency, ensuring use safety, and reducing daily management costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

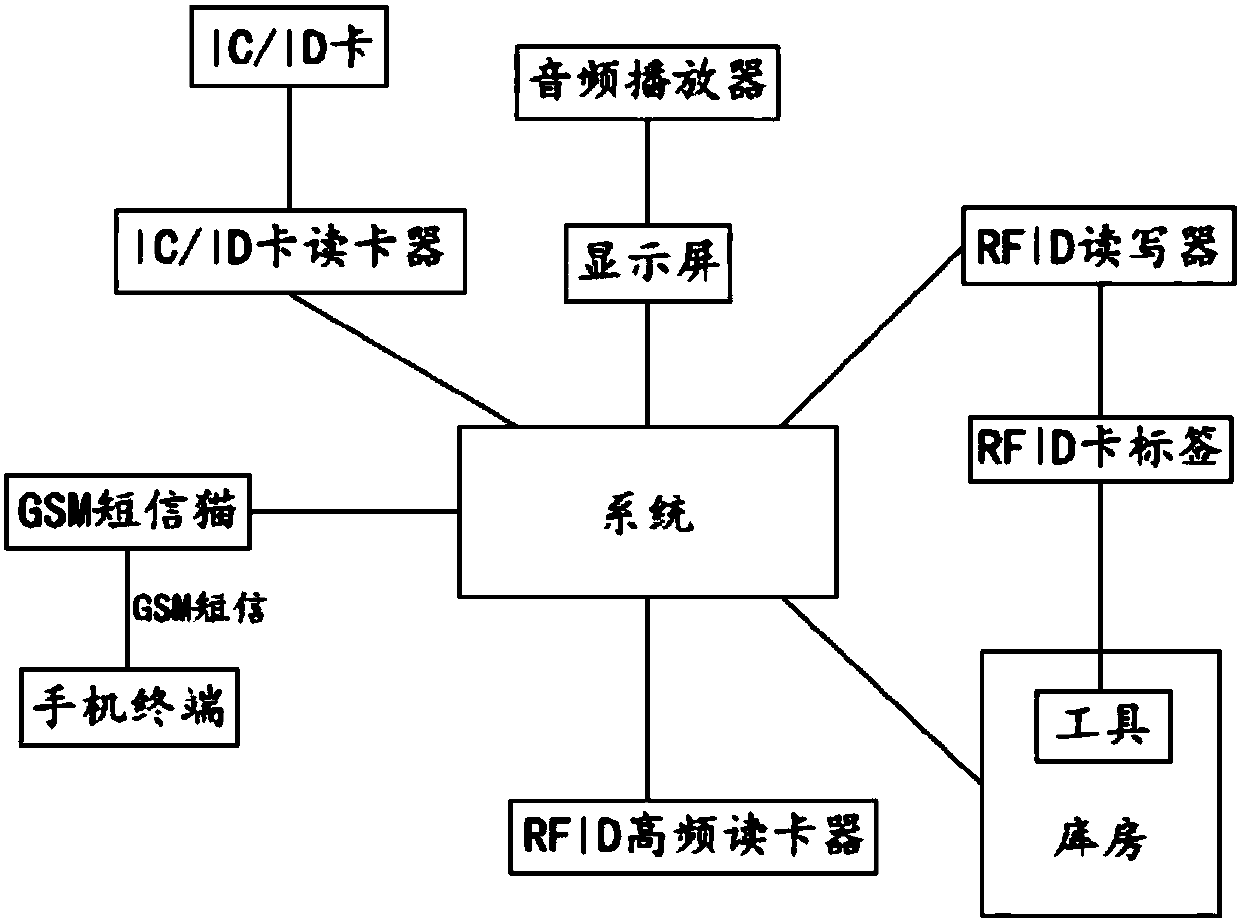

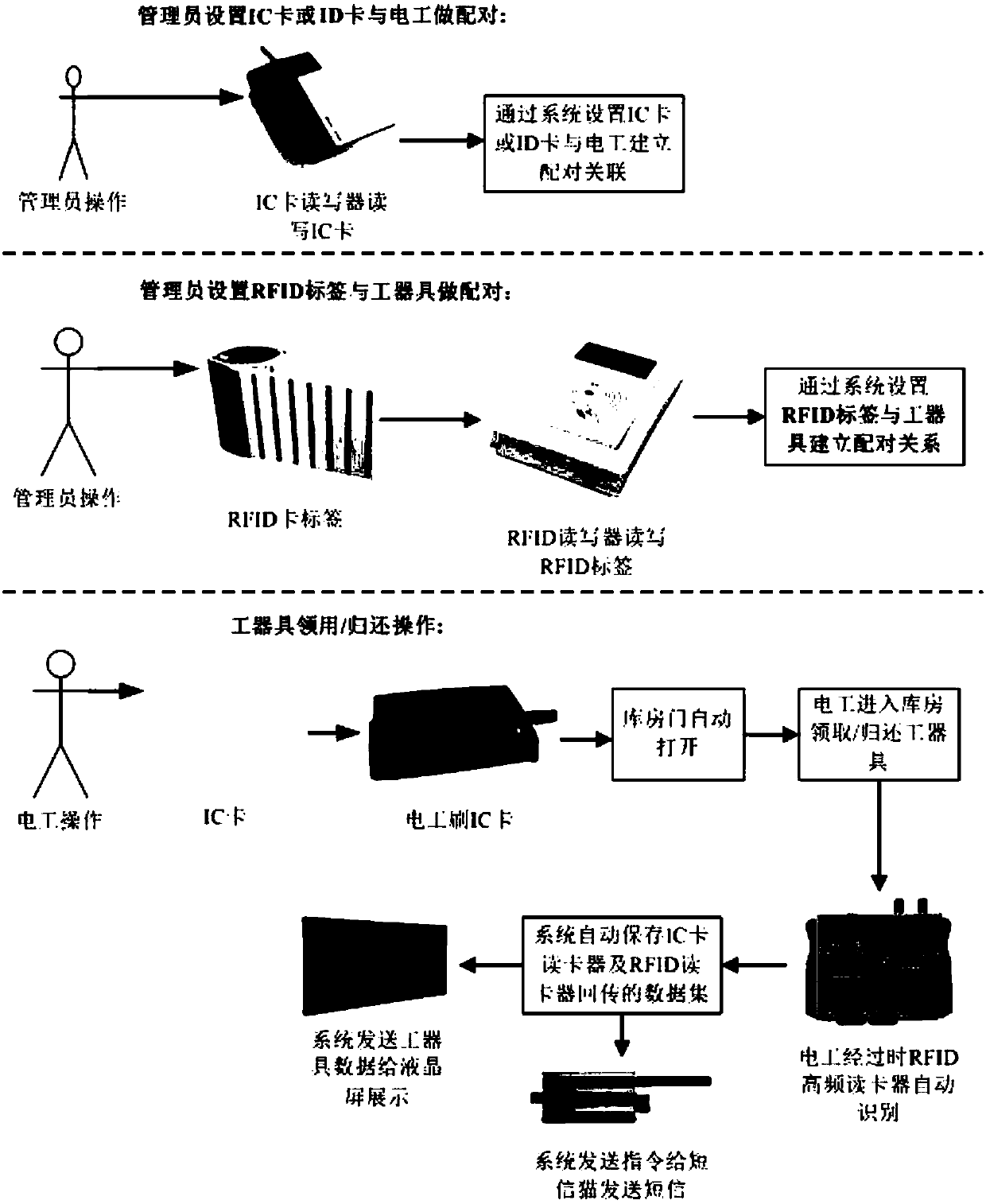

[0022] Such as figure 1 As shown, the present invention is an unattended intelligent management system for power supply station tool warehouse, including main control system, warehouse access control, IC / ID card reader, RFID card label, RFID card label reader, RFID high-frequency Card reader, GSM SMS modem, computer LCD screen and audio player. in:

[0023] Warehouse access control, connected with the main control system, and controlled by the main control system to open or close;

[0024] The IC / ID card reader is connected with the main control system through the interface program to read and write the IC / ID card, and realize the association between the IC / ID card and the electrical information;

[0025] RFID card label for st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com