Cleaning head for camera cleaning device

A technology of cleaning device and cleaning head, applied in the field of cleaning head, can solve the problems of labor, long operation time, time-consuming and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

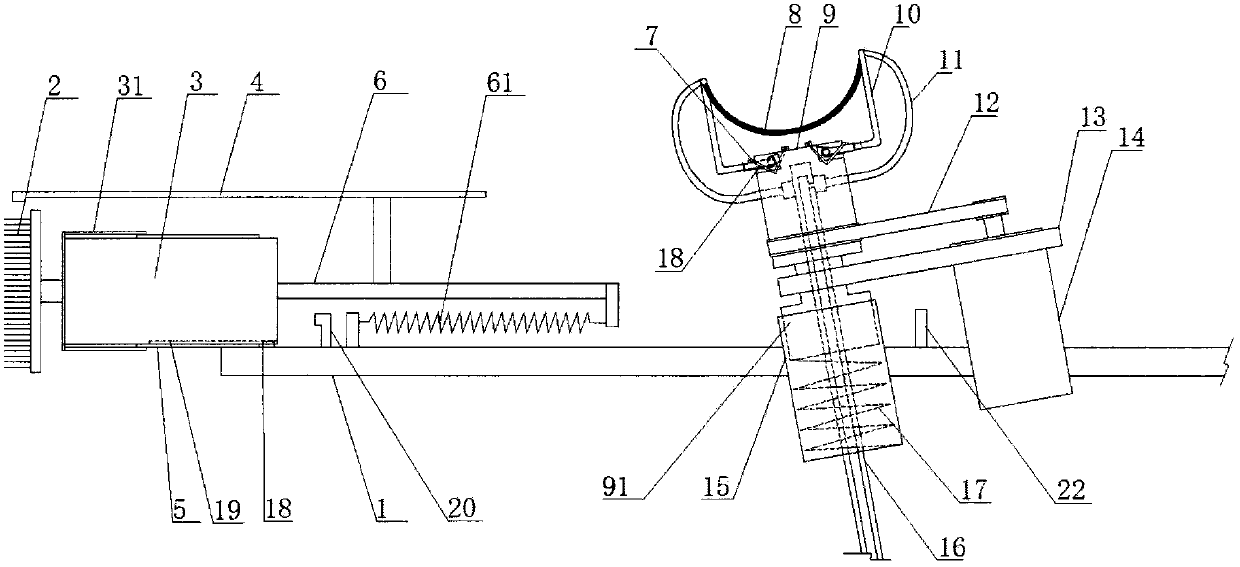

[0029] Such as figure 1 , Figure 5-Figure 7 A cleaning head for a camera cleaning device shown includes a connecting arm 1, which is provided with a spherical camera cleaning mechanism; the spherical camera cleaning mechanism includes a mounting seat 9 driven by a first drive motor 14, and the mounting seat A support 91 is arranged below 9, and the support 91 is connected with the connecting arm 1, and the first drive motor 14 is connected with the support 91 through a bracket 13; the mounting base 9 can rotate relative to the support 91. The mounting base 9 is movably connected with the connecting arm 1; at least a pair of cleaning tape brackets 10 are arranged on the mounting base 9, and flexible cleaning material is provided on the surface of the cleaning tape. Cleaning belt 8 is arranged between cleaning belt support 10; The connecting end 102 of cleaning belt support 10 and mounting base 9 is provided with the torsion spring 18 as reset mechanism, and mounting base 9 is...

Embodiment 2

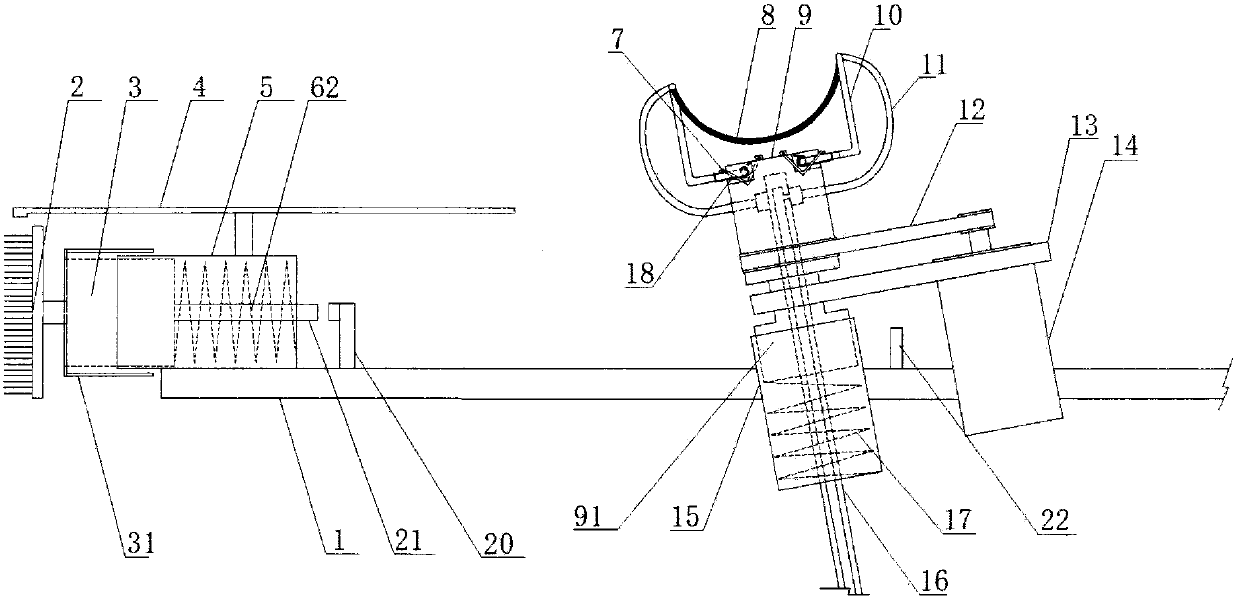

[0036] On the basis of Example 1, such as figure 2 As shown, the second driving motor 3 is arranged in a motor sleeve 5 , and a return spring 62 is arranged between the second driving motor 3 and the motor sleeve 5 . When the contact force between the cleaning head 2 and the surface of the camera is too large, the return spring 62 is compressed to store force, and when the contact force becomes smaller, the second driving motor 3 together with the cleaning head 2 moves to the initial position under the action of the spring force.

[0037] Such as figure 2 As shown, as an improved solution, a limit switch 20 is provided on the connecting arm 1, and a contact rod 21 is provided at the rear of the second driving motor 3. The contact rod 21 passes through the rear of the motor sleeve 5 and is aligned with the limit switch. bit switch 20. The limit switch 20 is connected with a mechanism for controlling the multi-directional movement of the connecting arm 1. This mechanism can ...

Embodiment 3

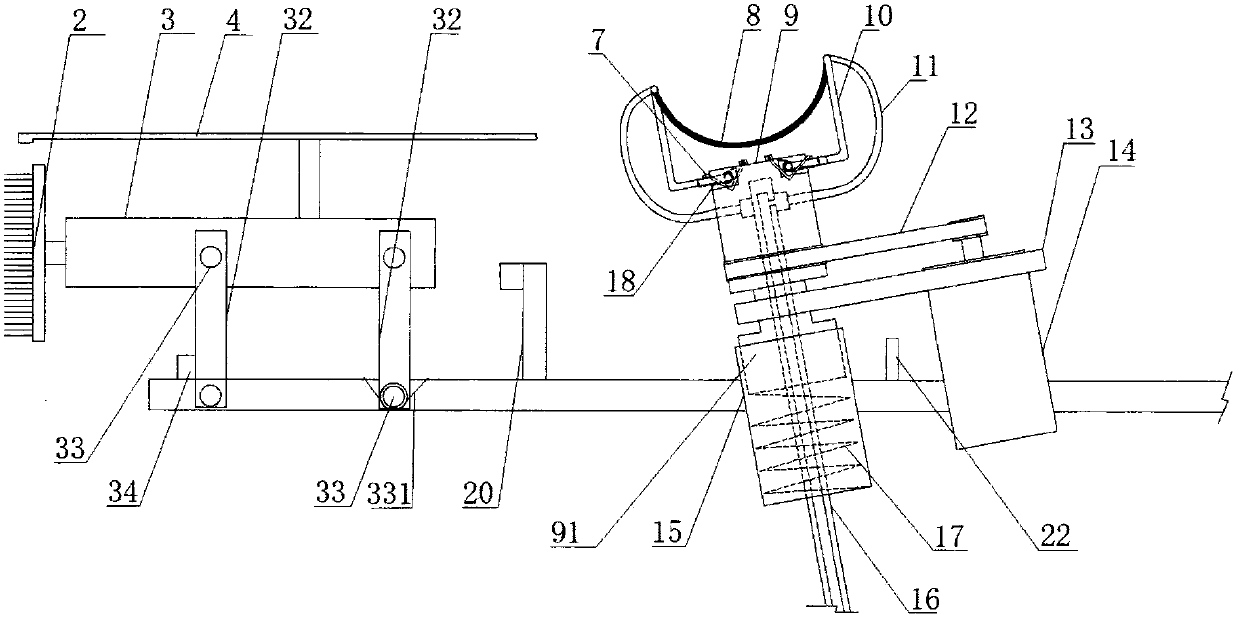

[0040] On the basis of Example 1, such as image 3 As shown, the second drive motor 3 is hinged to the connecting arm 1 through two vertical connecting rods 32 , and shafts 33 are arranged at the hinges, and a reset torsion spring 331 is arranged on one of the shafts 33 . A block 34 for blocking the vertical link 32 and limiting its initial position is also arranged on the connecting arm 1 .

[0041] Such as image 3 As shown, as an improved solution, a limit switch 20 is set on the connecting arm 1, the limit switch 20 is located behind the second drive motor 3, and the limit switch 20 is connected to a mechanism for controlling the multidirectional movement of the connecting arm 1. The mechanism of the prior art can be adopted, and the purpose is to realize the control of the front and rear, left and right and up and down movements of the connecting arm. When the contact force between the cleaning head 2 on the second driving motor 3 and the surface of the camera is too la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com