Dislodgement overturning mechanism

A flipping mechanism and displacement technology, which is applied to tin feeding devices, metal processing equipment, manufacturing tools, etc., can solve problems such as difficult operation, and achieve the effect of no impact force, precise positioning, and smooth flipping action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

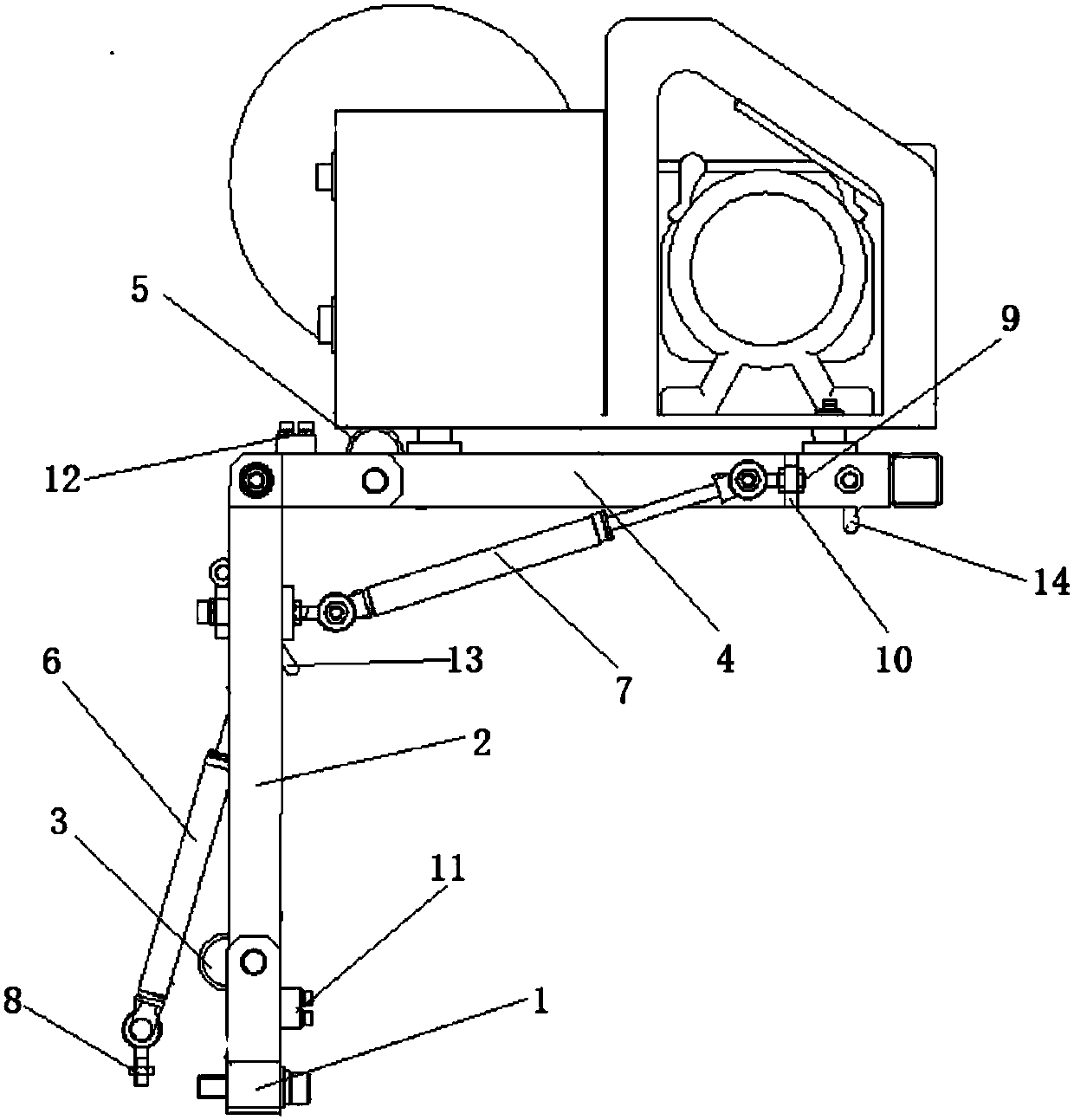

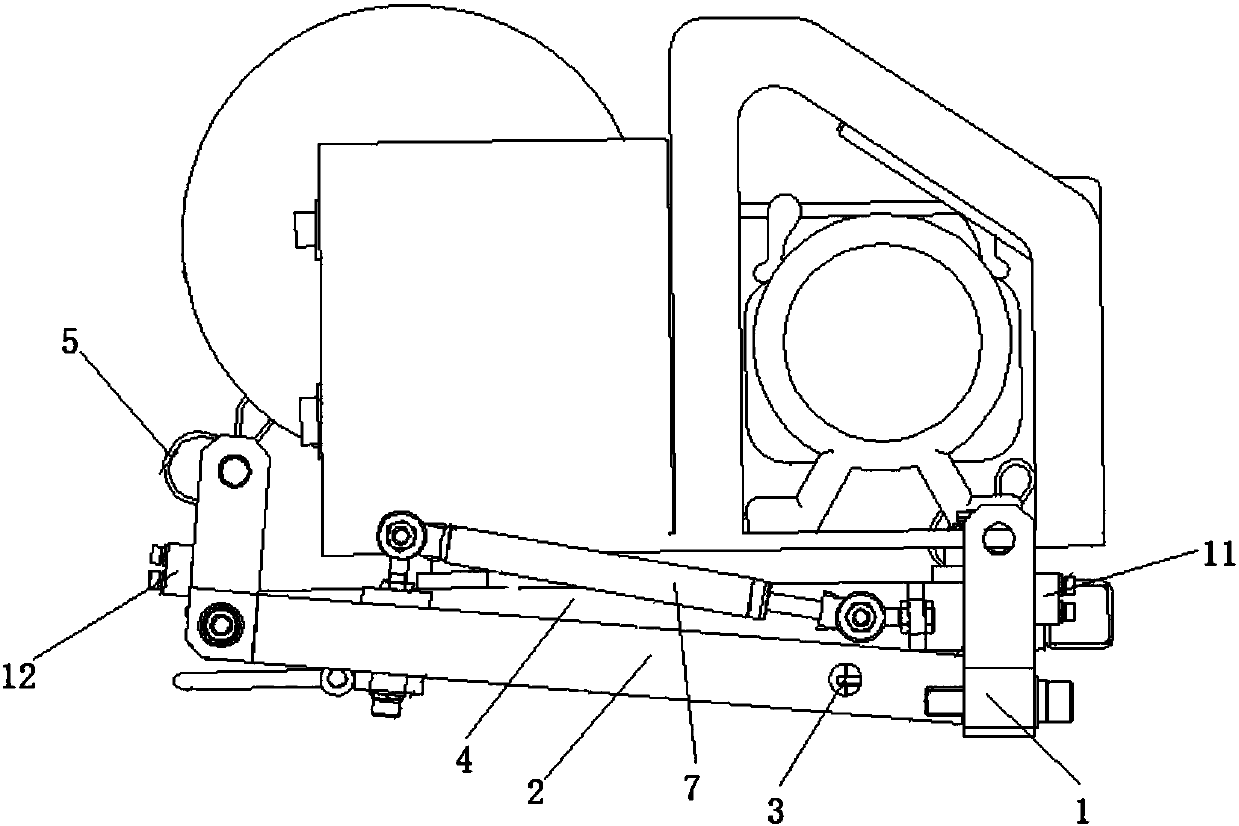

[0020] A displacement and turning mechanism provided in this embodiment has a structure such as Figure 1-2 shown.

[0021] This mechanism comprises fixed seat 1, and vertical arm 2 is hinged on fixed seat 1, and vertical arm 2 is provided with lock pin one 3 near fixed seat 1, and vertical arm 2 and fixed seat 1 are detachably fixed by lock pin one, vertical arm 2 The other end of arm 2 is hinged with cross arm 4, and cross arm 4 is provided with two lock pins 5 close to vertical arm 2 and cross arm 4 hinged positions, and two lock pins 5 are detachably fixed by vertical arm 2 and cross arm 4. Air spring one 6 and air spring two 7 are arranged on the vertical arm 2 close to the hinged part of the vertical arm 2 and the cross arm 4. One end of the air spring one 6 and the air spring two 7 is a fixed end, and the other end is a free end and is provided with a fixed spring. Part one 8 and fixing part two 9, the vertical arm 2 is provided with a fixed part one detachably matched...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com