A seam welding lead-out board clamping device for ship puzzles

A technology of clamping device and lead-out plate, which is applied in the direction of welding equipment, auxiliary equipment, auxiliary welding equipment, etc., can solve the problems of low work efficiency, damage to the end of parts, and influence on welding quality, so as to improve work efficiency, save costs, The effect of reducing the grinding workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

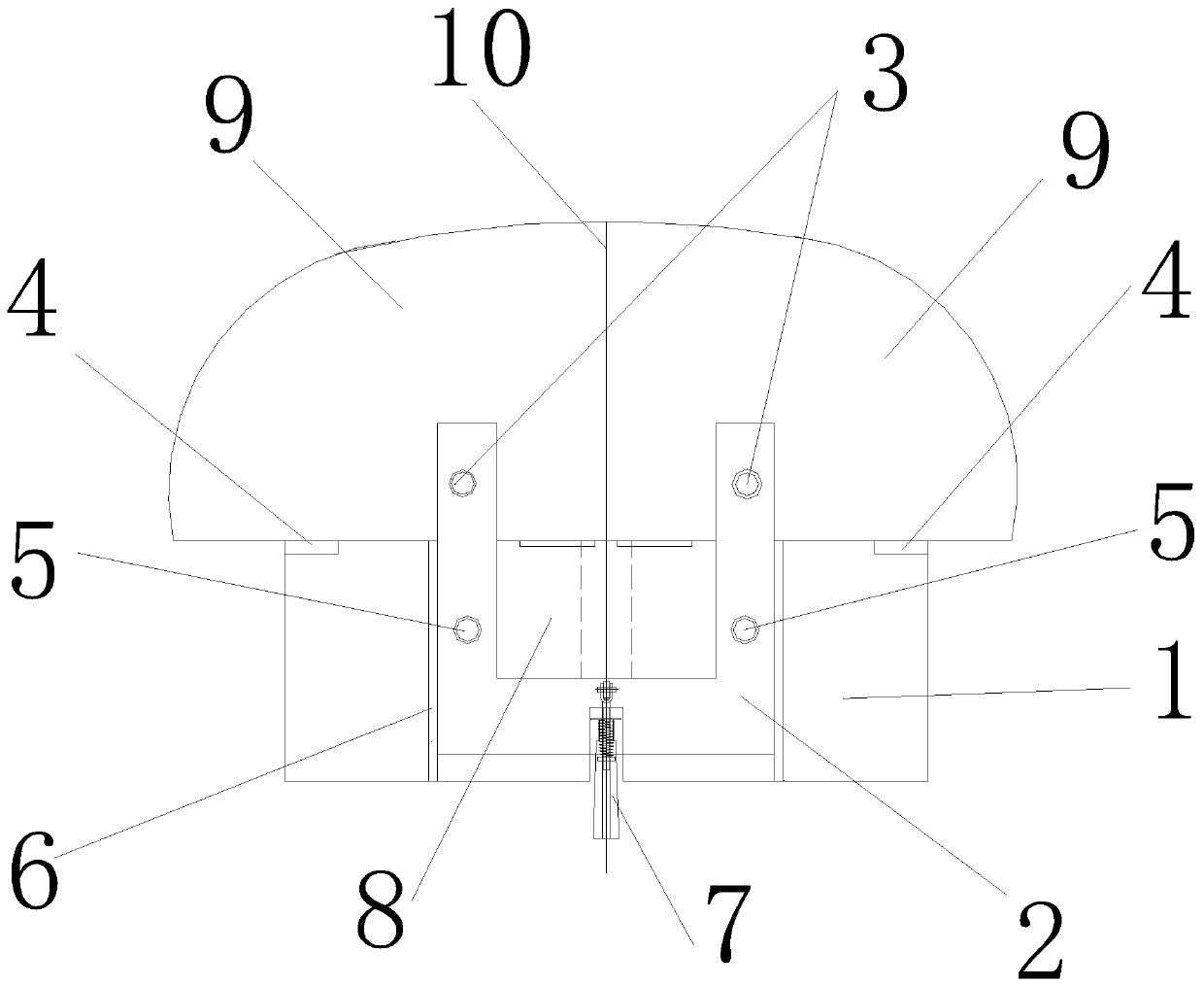

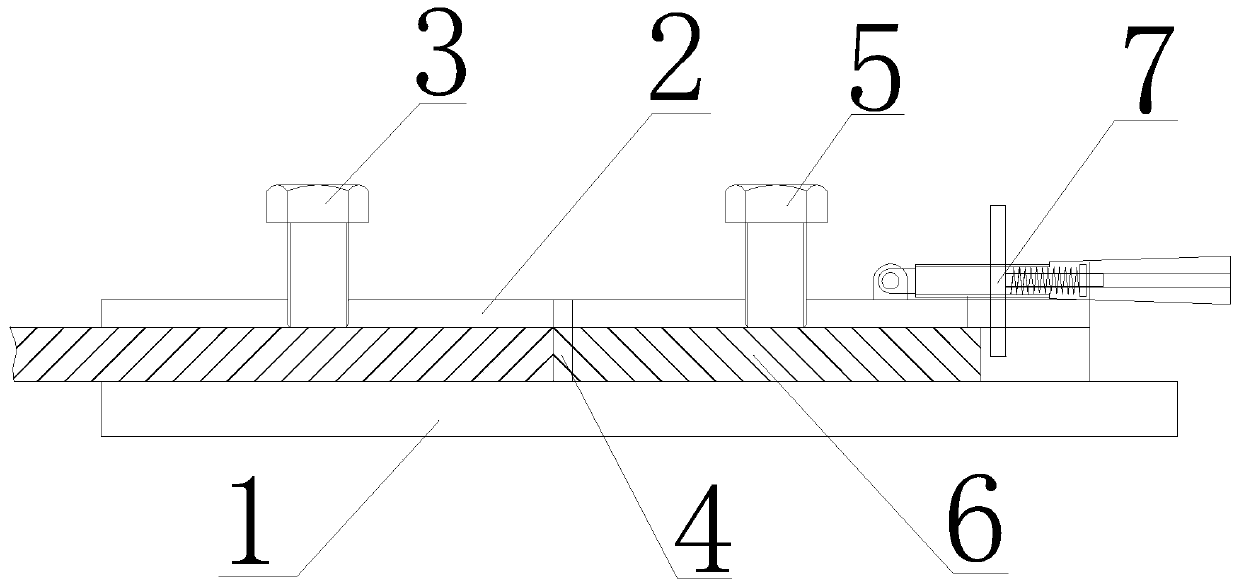

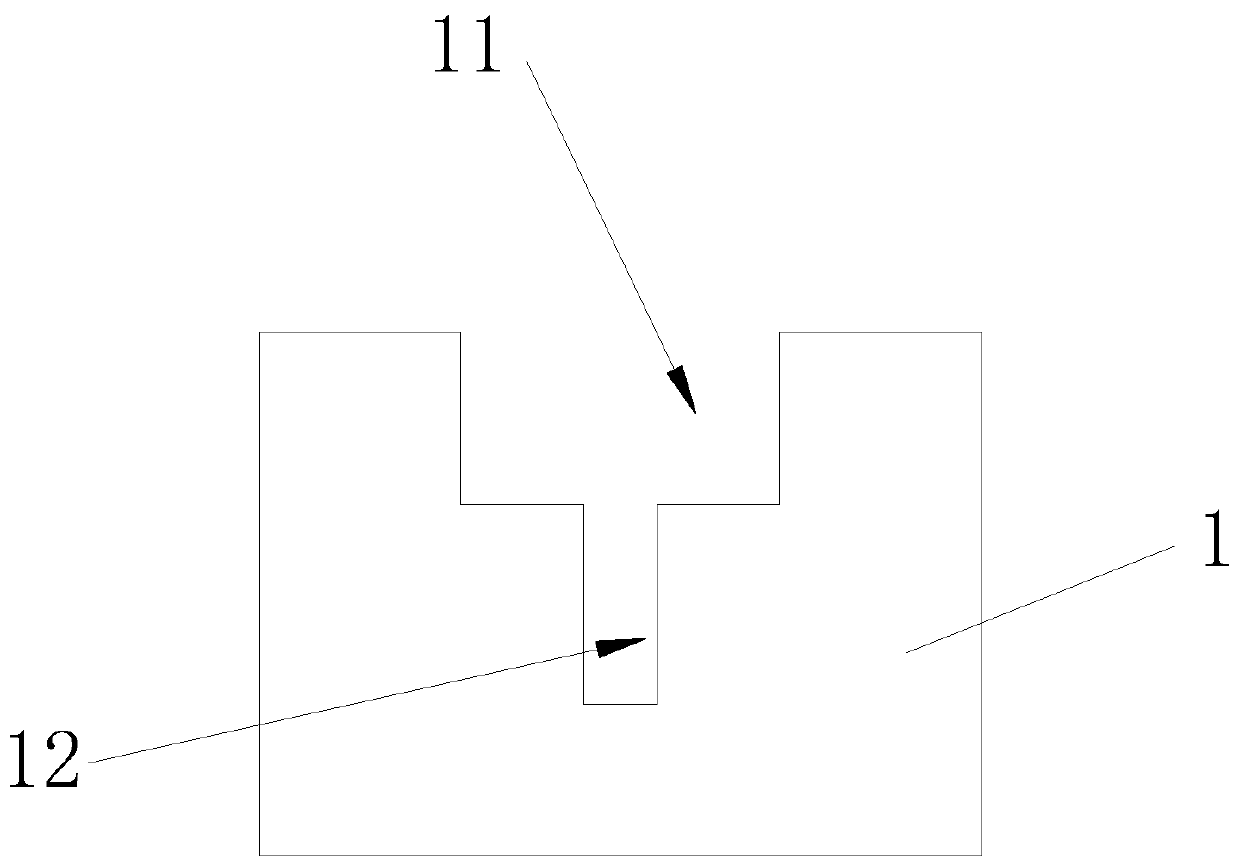

[0020] Such as figure 1 , 2 As shown, this embodiment provides a ship panel seam welding lead-out plate clamping device, which is used to fix the lead-out plate 8 at the weld 10 of the welded part 9, including a bottom plate for supporting the lead-out plate 8 and determining the installation position 1, and the top plate 2 fixed on the bottom plate 1, the top plate 2 respectively locates and fixes the lead-out plate 8 from the horizontal position and the front and rear positions, and connects and fixes the clamping device with the welding part 9.

[0021] The present invention installs and fixes the lead-out plate 8 through the bottom plate 1 and the top plate 2, fixes the clamping device on the end of the welding part 9, places the weld lead-out plate 8, and uses a tightening device to fix the lead-out plate 8, and subsequent welding can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com