LTCC integrated refrigeration system based on heat pipe and thermoelectric cooler and its manufacturing method

A thermoelectric refrigerator and refrigeration system technology, applied in the direction of machine operation, refrigerators, electric solid devices, etc., can solve the problems of difficult process, difficult to meet the refrigeration requirements of LTCC microsystems, and difficult precise processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

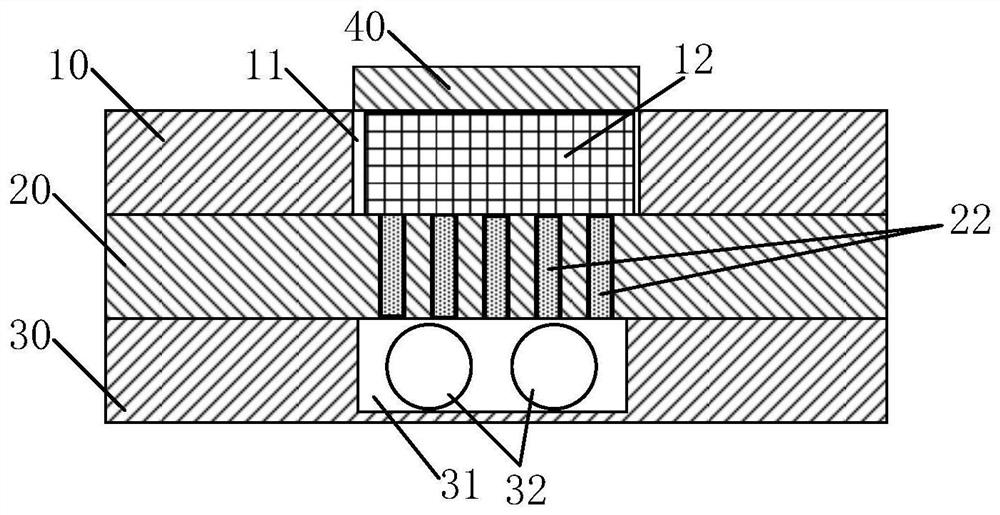

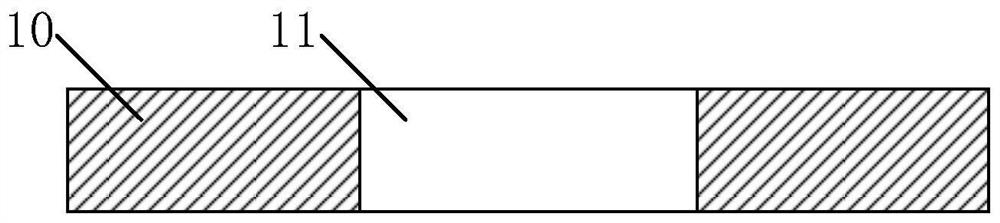

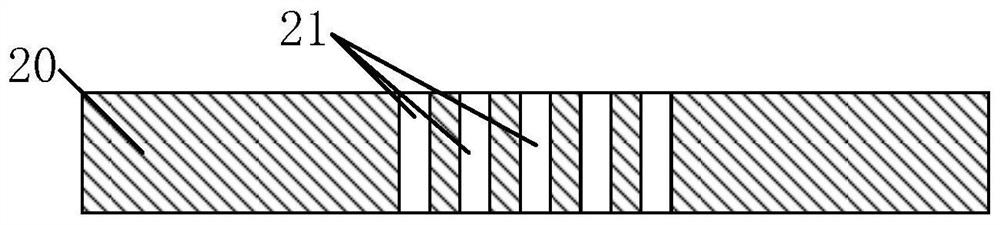

[0057] The first aspect of the embodiments of the present invention provides an LTCC integrated refrigeration system based on heat pipes and thermoelectric coolers, please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 9 As shown, an LTCC integrated refrigeration system based on heat pipes and thermoelectric coolers includes: thermoelectric coolers 12, heat pipe assemblies 32, and lower tiles 30, middle tiles 20, and upper tiles 10 arranged in sequence from bottom to top. In this embodiment, a thermoelectric cooler (Thermo Electric Cooler, TEC) is also called a semiconductor cooler or a semiconductor cooling chip. The upper ceramic sheet 10, the middle layer ceramic sheet 20 and the lower layer of green ceramic sheet are bonded together. The upper tile 10 is provided with a mounting through hole 11 . The thermoelectric cooler 12 is fixed in the installation through hole 11 , the hot end of the thermoelectric cooler 12 is flush with the lower...

Embodiment 2

[0061] This embodiment is improved on the basis of the first embodiment.

[0062] Such as Figure 6 As shown, further, an LTCC integrated refrigeration system based on heat pipes and thermoelectric coolers also includes thermal conductive glue 33 . The thermal conductive glue 33 is filled in the installation groove 31 , and the thermal conductive glue 33 is in contact with the metal post 22 . The heat pipe assembly 32 is fixed in the installation groove 31 by a thermally conductive glue 33 . In this embodiment, the heat pipe assembly 32 is fixed in the installation groove 31 by the heat conduction glue 33, the heat conduction glue 33 is filled with the installation groove 31, and the lower ends of the plurality of metal posts 22 extend to the opening of the installation groove 31, so the metal pillars 22 and When the heat-conducting glue 33 contacts, the heat of the metal pillar 22 is transferred to the heat-conducting glue 33 , and the heat-conducting glue 33 transfers the ...

Embodiment 3

[0068] see Figure 1-Figure 7 , The second aspect of the embodiment of the present invention provides a method for manufacturing an LTCC integrated refrigeration system based on heat pipes and thermoelectric coolers, including: Step S1-Step S6. The production method of this embodiment is batch production, and multiple LTCC integrated refrigeration systems based on heat pipes and thermoelectric coolers in any of the above-mentioned embodiments can be obtained.

[0069] Step S11 is also included before step S1: classification of green porcelain fragments. Pre-drying a plurality of green porcelain fragments, and then dividing the multiple green porcelain fragments into three categories, namely a plurality of upper layer green porcelain fragments, a plurality of middle layer green porcelain fragments and a plurality of lower layer green porcelain fragments. The porcelain fragments, the middle green porcelain fragments and the lower green porcelain fragments are manufactured accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com