Housing assembly of double-side grinding machine

A double-sided grinding machine and shell technology, which is applied in the directions of grinding machines, grinding beds, grinding racks, etc., can solve problems such as increased production costs, complex workshop layout, and dust generation, so as to reduce the use of space and reduce production costs. , good effect of dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

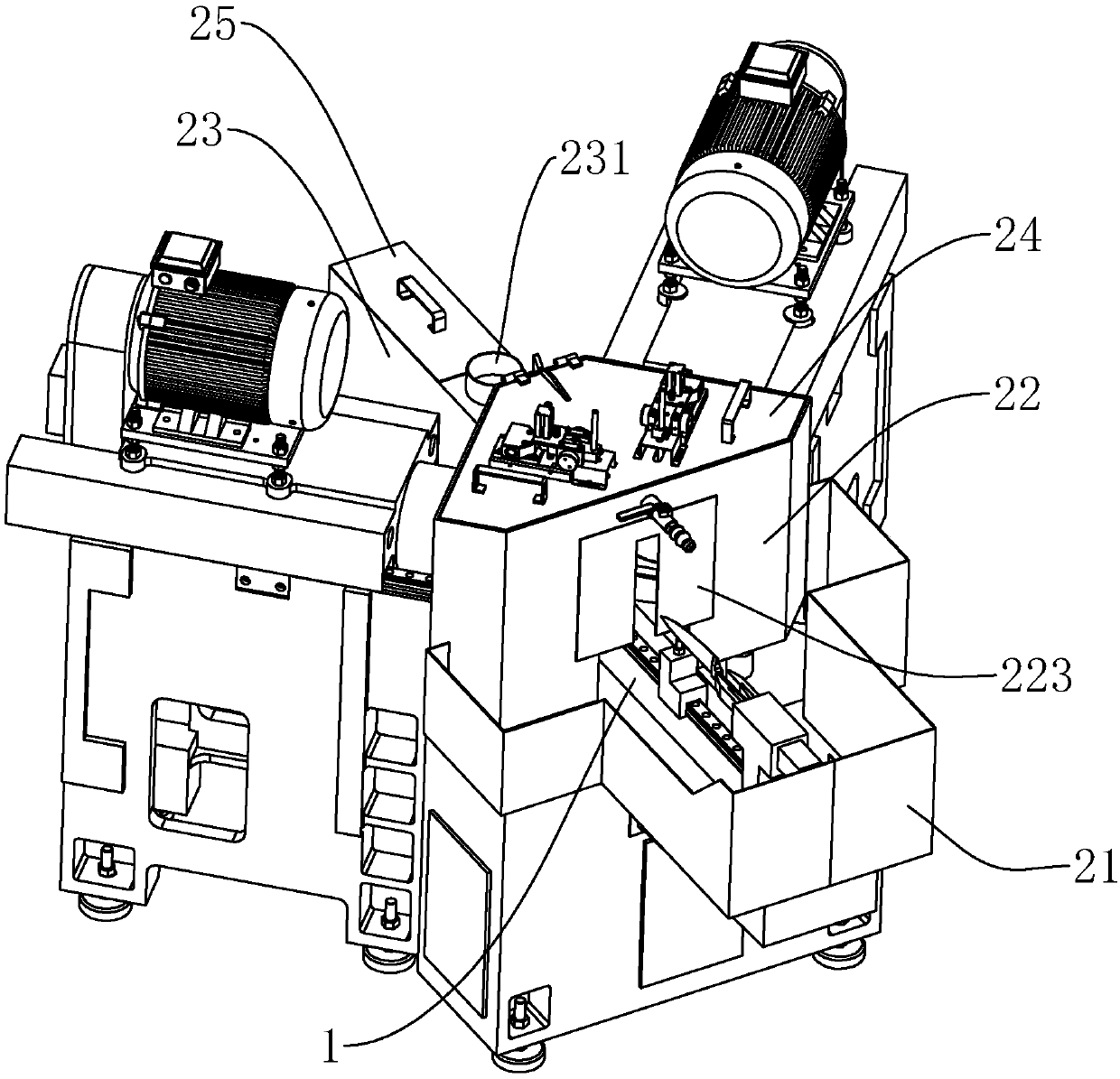

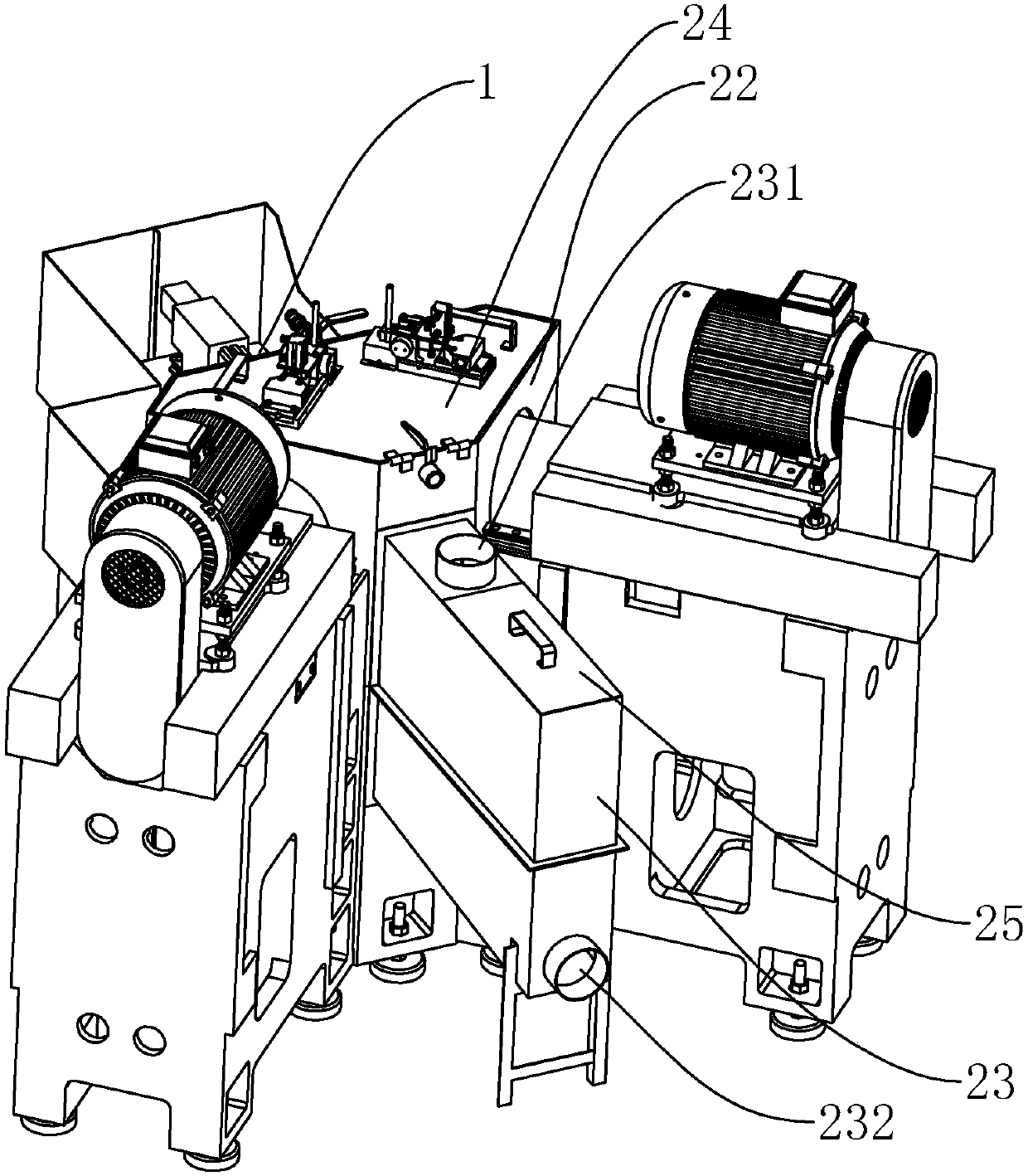

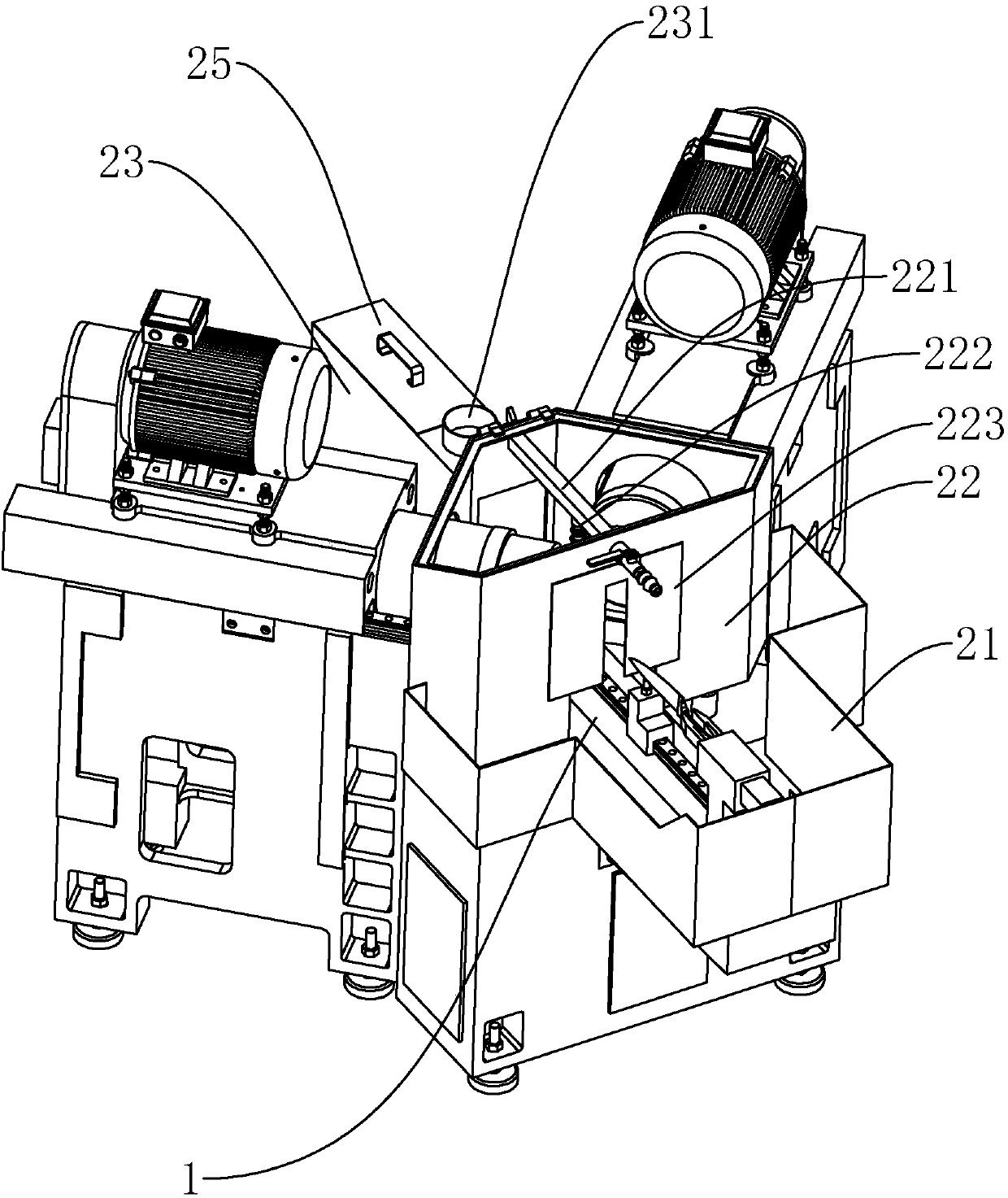

[0016] Reference Figure 1 to Figure 3 , Figure 1 to Figure 3 It is a schematic structural diagram of a specific embodiment of the present invention. As shown in the figure, the housing assembly of the double-sided grinder includes a housing assembly arranged on the workbench 1 of the grinder, and the housing assembly includes a side enclosed on the side of the workbench 1. Shell 21, a rear shell 23 arranged on the rear side of the workbench 1, the rear shell 23 communicates with the side shell 21, and a dust removal port 231 connected to a negative pressure device is provided above the rear shell 23, so that the processing position of the grinder Negative pressure is formed at the place, and the dust will not leak out, but will be discharged through the negative pressure equipment. The dust removal effect is good, and the shell integrates the dust removal function, which can replace the workshop dust removal equipment, reduce production costs, and reduce the use of space, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com