Heavy-load wheel type robot adjustable suspension device

A wheeled robot and suspension device technology, applied in the field of robotics, can solve the problems such as the inability to adjust the up and down stroke of the suspension more accurately, and achieve the effects of increasing the passability of the chassis, improving the ability to maintain attitude, and improving the passability of the chassis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

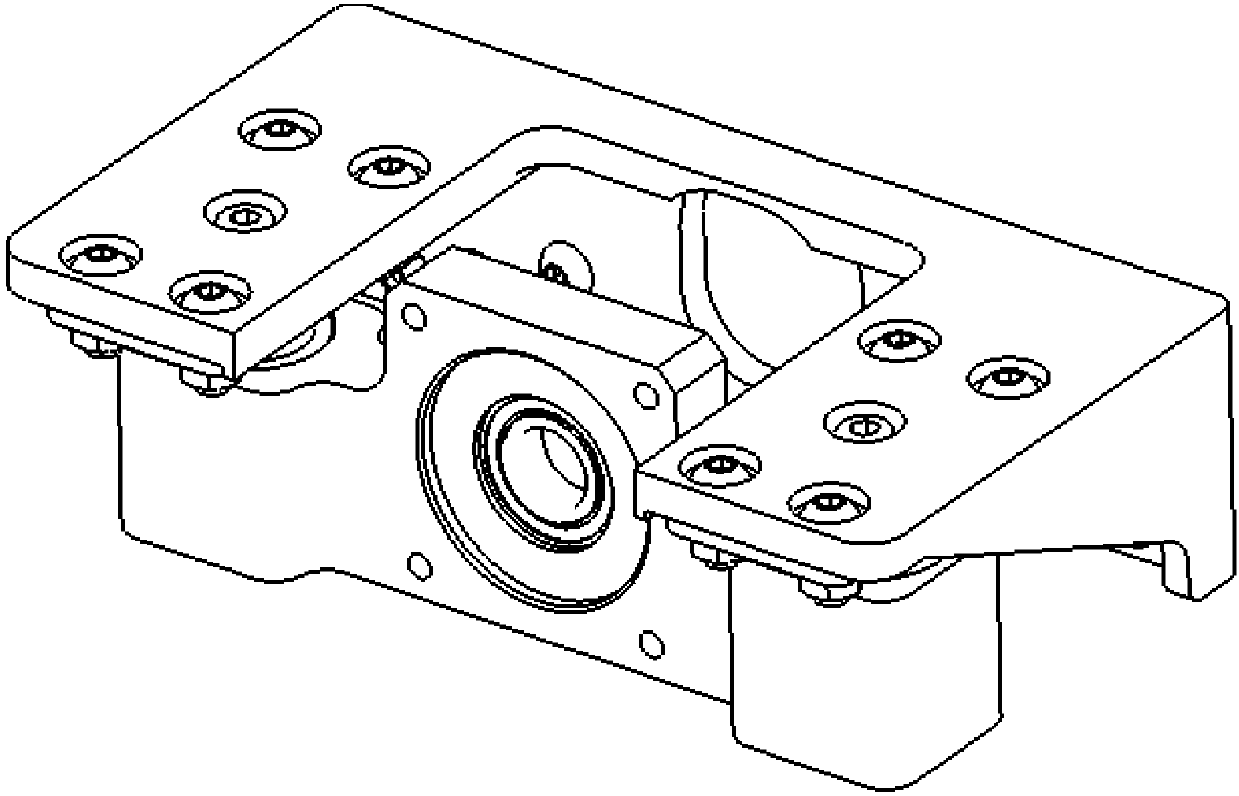

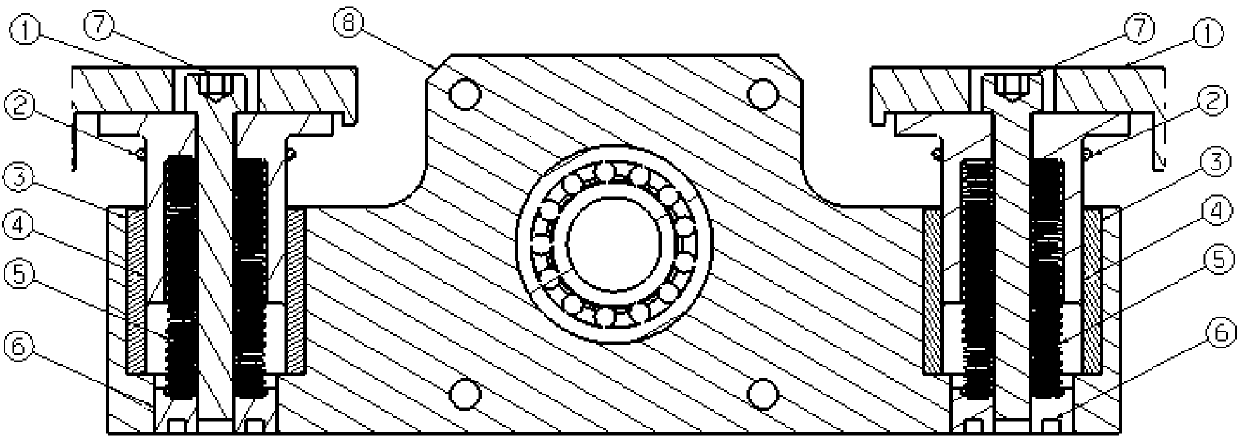

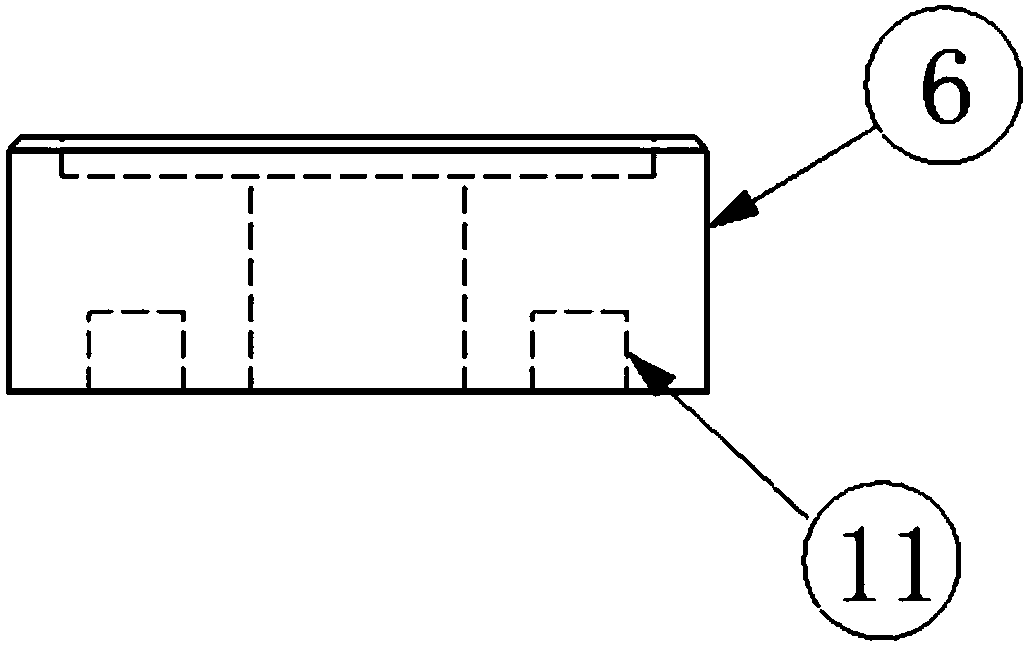

[0027] like figure 1 , 2 As shown, an adjustable suspension device for a heavy-duty wheeled robot provided in this embodiment includes a suspension support 8, the suspension support 8 adopts a symmetrical design, and a guide groove is opened on each side, and the groove wall serves as a guide The fixed end of the device; the mobile end 4 of the guide device is fixedly connected with the frame 9 through the adapter seat 1; The sliding bearings 3 slide between the seats 8, so that the sliding bearings 3 can be used to slide up and down, and the moving end 4 of the guide device and the suspension support 8 can be used to protect the sliding bearings 3 from radial damage. The spring 5 is used as the elastic element, the upper end of the spring 5 is inserted into the inner cavity of the moving end 4 of the guide device, supported by the inner cavity wall, and the lower end is only supported by the lead adjustment block 6; the lead adjustment block 6 is installed on the suspension ...

Embodiment 2

[0040] An adjustable suspension device for a heavy-duty wheeled robot provided in this embodiment includes a suspension support 8 on which an independent fixed end of the guiding device is arranged; the moving end 4 of the guiding device is directly fixed to the frame 9 Connection; the moving end 4 of the guiding device is in contact with the fixed end of the guiding device through a linear bearing; the spring 5 is used as the elastic element, the upper end of the spring 5 is inserted into the inner cavity of the moving end 4 of the guiding device, supported by the inner cavity wall, and the lower end is only adjusted by the lead The block 6 is supported; the lead adjustment block 6 is installed in the lead adjustment block installation hole of the suspension support 8, and can move along the lead direction; the adjustment rod 7 passes through the moving end 4 of the guide device and the spring 5, and the upper end is covered with a nut , through the nut limit, the limit guidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com