Storage device of liquid additives for papermaking

A technology of liquid additives and storage devices, applied in the direction of internal accessories, etc., can solve problems such as inconvenient access and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

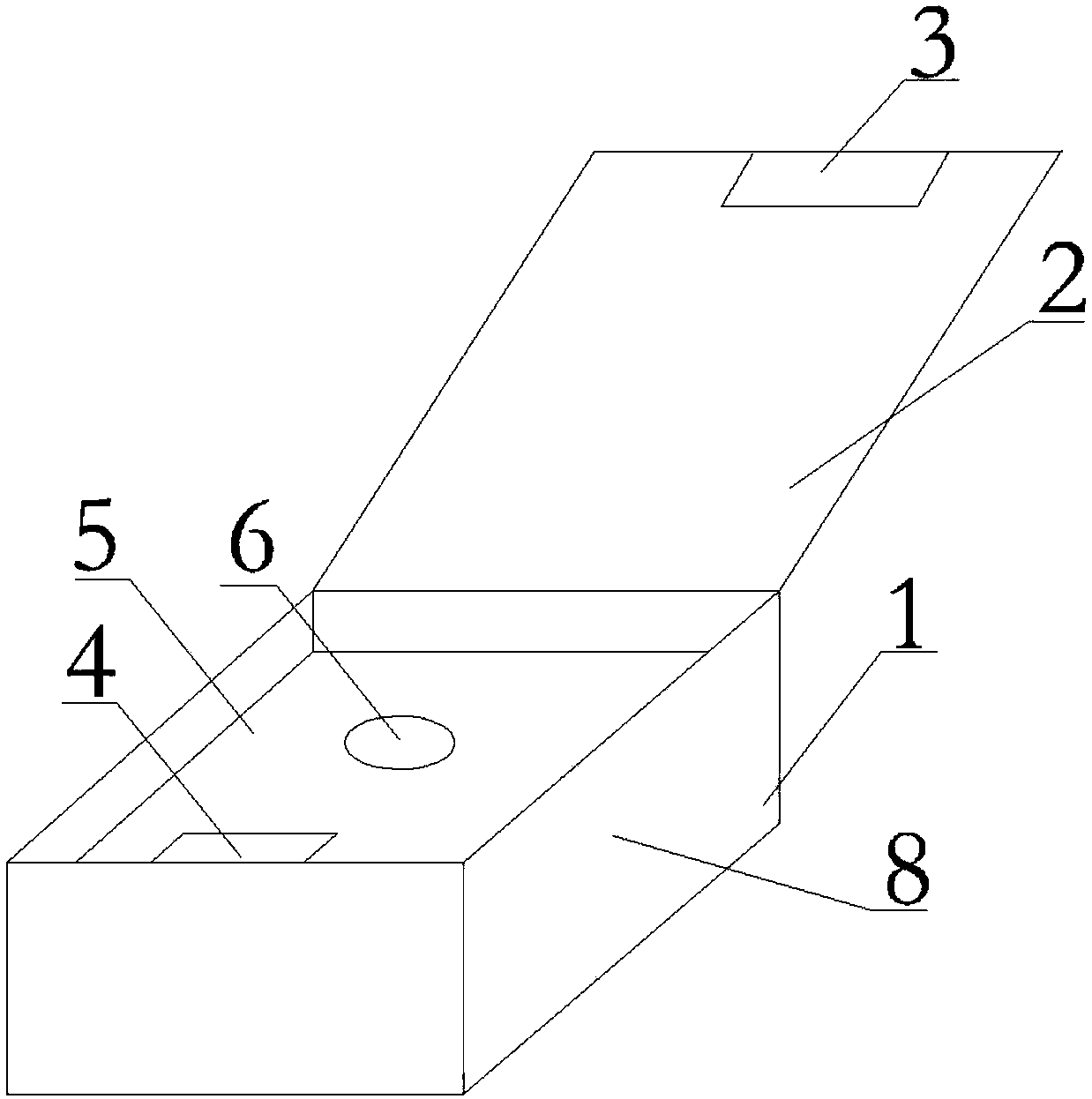

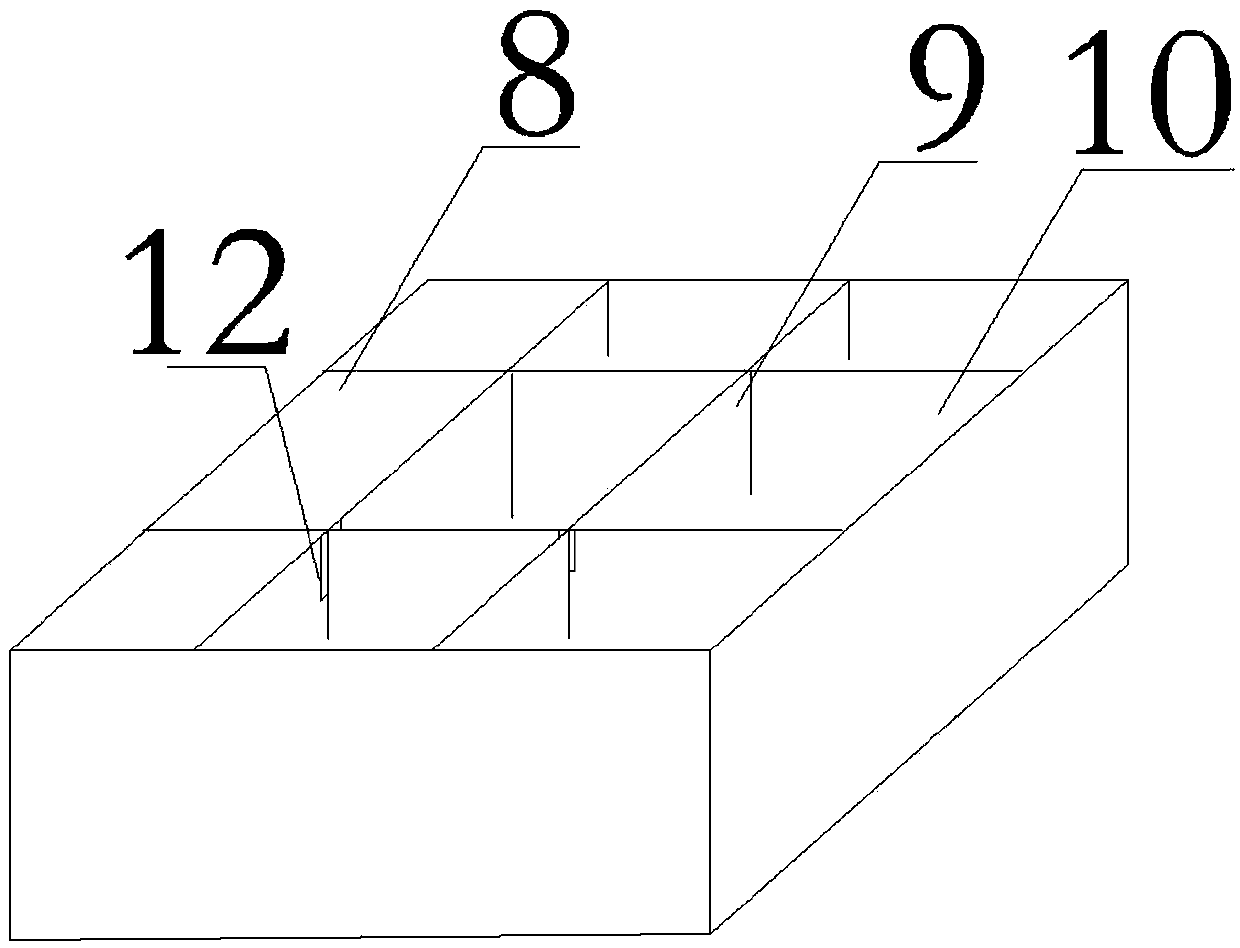

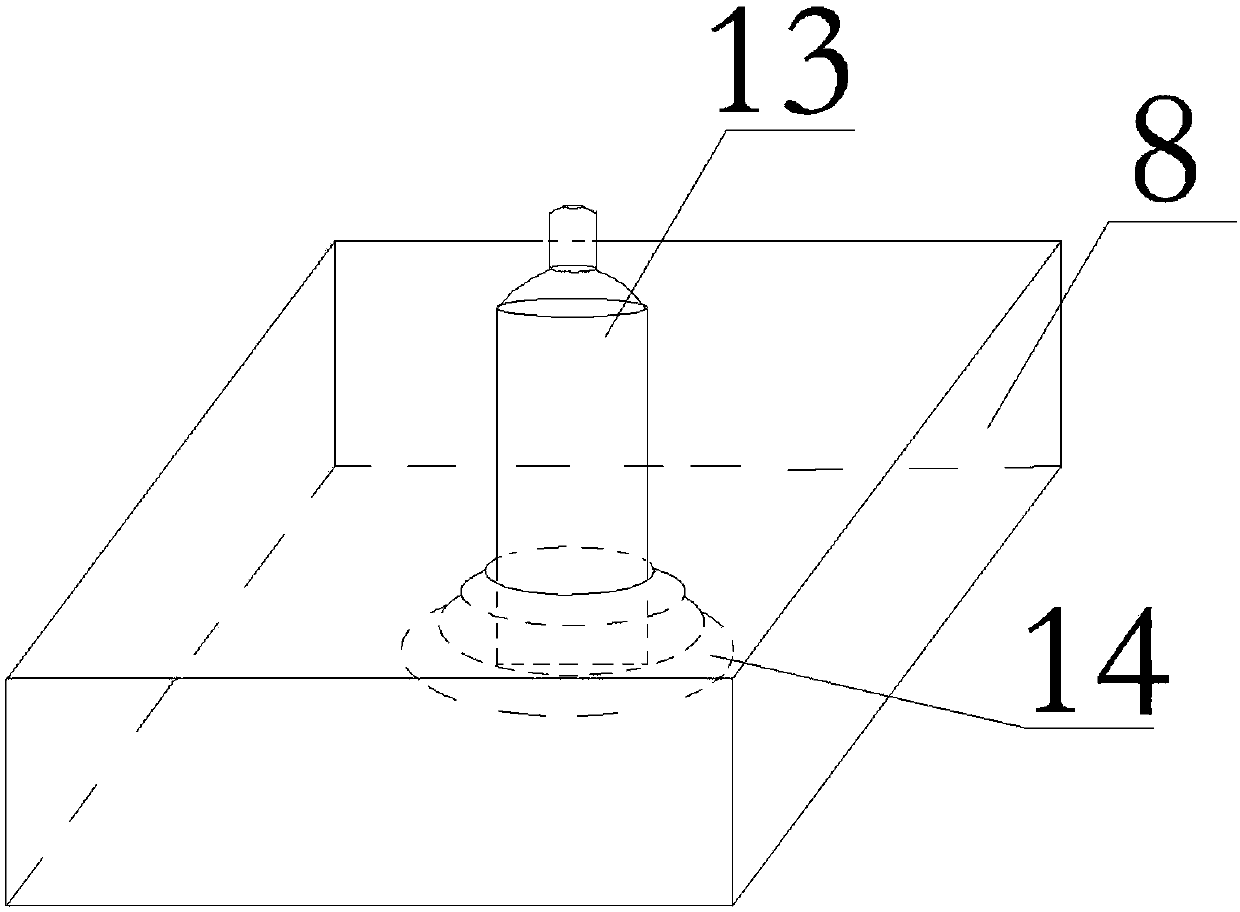

[0020] Such as figure 1 , figure 2 , image 3 As shown, a storage device for liquid additives for papermaking, including a packaging bag body, the packaging bag body includes a box body 1, a box cover 2, the box cover 2 is hinged to one end of the box body 1, and the box body 1 is provided with a cover plate 5 , the center of cover plate 5 is provided with the penetrating hole 6 that is convenient for liquid auxiliary agent bottle 13 to pass through; Box body 1 is provided with liquid additive bottle placement area 8, and liquid additive bottle placement area 8 is provided with transverse septum 10, mediastinum Sheet 9, transverse septum 10 and longitudinal septum 9 intersect each other to separate the liquid additive bottle placement area 8 into a plurality of cavities for liquid auxiliary agent bottles 13, the longitudinal septum 9 is provided with a first through slot 12, the first The vertical height of the through slot 12 is less than the height of the longitudinal sep...

Embodiment 2

[0029] This embodiment is further defined on the basis of the embodiment, the transverse septum 10 and the longitudinal septum 9 are perpendicular to each other, and the cavity formed by the crossing of the transverse septum 10 and the longitudinal septum 9 is provided with a bottle for easy adjustment of the lower part of the liquid auxiliary agent bottle. The accommodating hole 14 whose outer periphery is fixed, the accommodating hole 14 is composed of a plurality of rings with different apertures, the rings are stacked sequentially from bottom to top, and the apertures of the rings are successively reduced from bottom to top. This embodiment considers to further strengthen the fixing of the liquid auxiliary agent bottle, the penetration hole 6 fixes the top opening of the liquid auxiliary agent bottle 13, and the main function of using the receiving hole 14 is to fix the lower end of the liquid auxiliary agent bottle, The cross-section of the lower end of the liquid auxiliar...

Embodiment 4

[0031] The difference between this embodiment and the above-mentioned embodiment is that: the inner side of the edge of the box cover 2 is provided with a protruding bar 3 , and the cover plate 5 is provided with a penetration groove 4 which facilitates the insertion of the protruding bar 3 . The main effect of setting out protruding bar 3, penetrating groove 4 is that lid 2 is closed on box body 1, avoids opening automatically in transportation process. Wherein the protruding bar 3 is a plate-like structure, such as a quadrilateral, one end of which is fixedly connected to the lid 2, and the other end is a free end, and the protruding bar 3 is perpendicular to the lid 2, and can be vertically inserted into the box body 1. Into the groove 4, the structure of the penetration groove 4 is adapted to the shape of the protruding strip 3. Therefore, other structures involved in this embodiment are well known to those skilled in the art and will not be described in detail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com