Horizontal moving molten iron stirring desulfurization system

A stirring desulfurization and lateral moving technology, which is applied in molten iron pretreatment and metallurgy fields, can solve the problems of wasteful land occupation and easy shaking of the structural platform, and achieve the effect of saving land occupation space and equipment cost, and avoiding shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

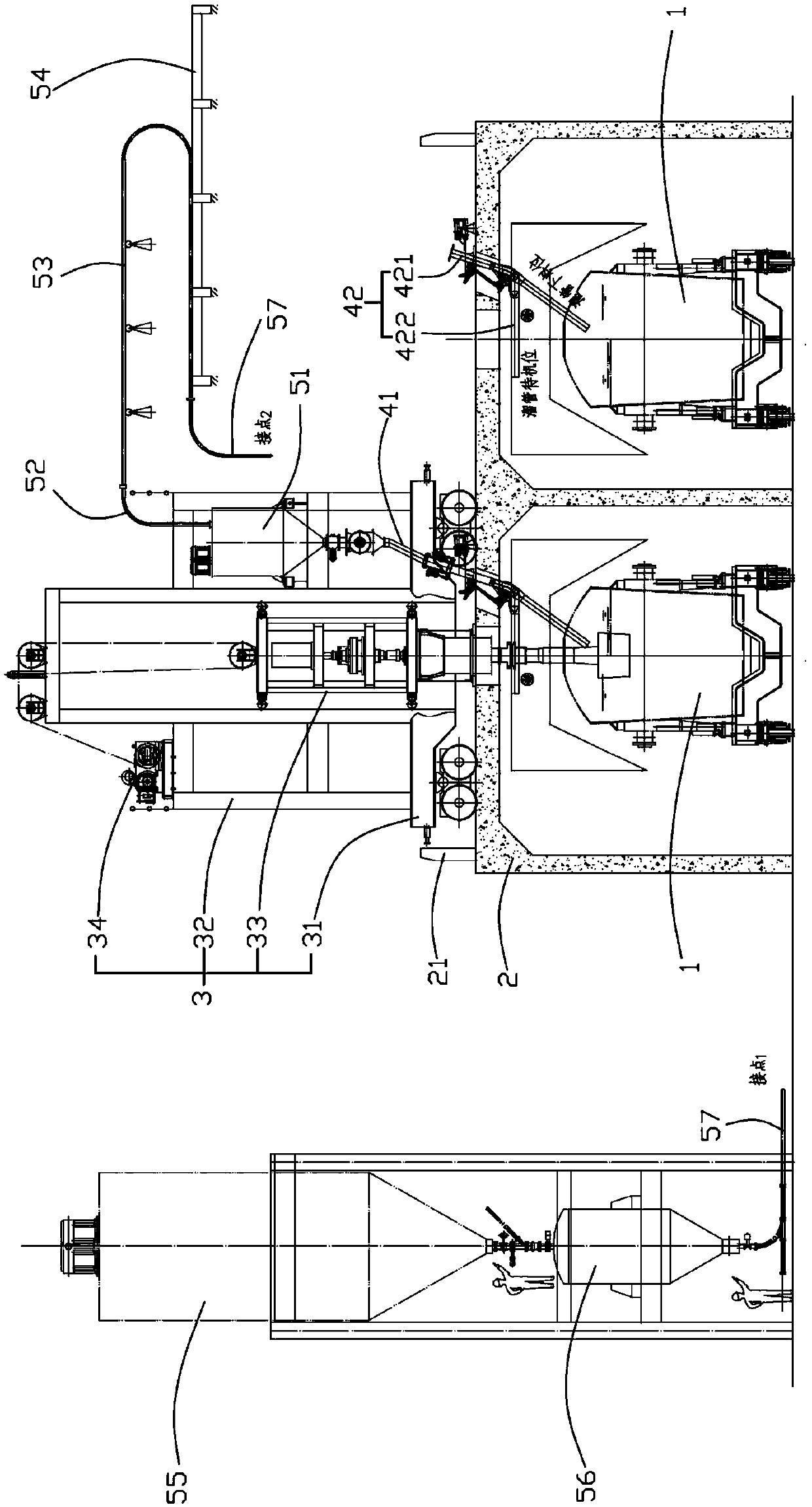

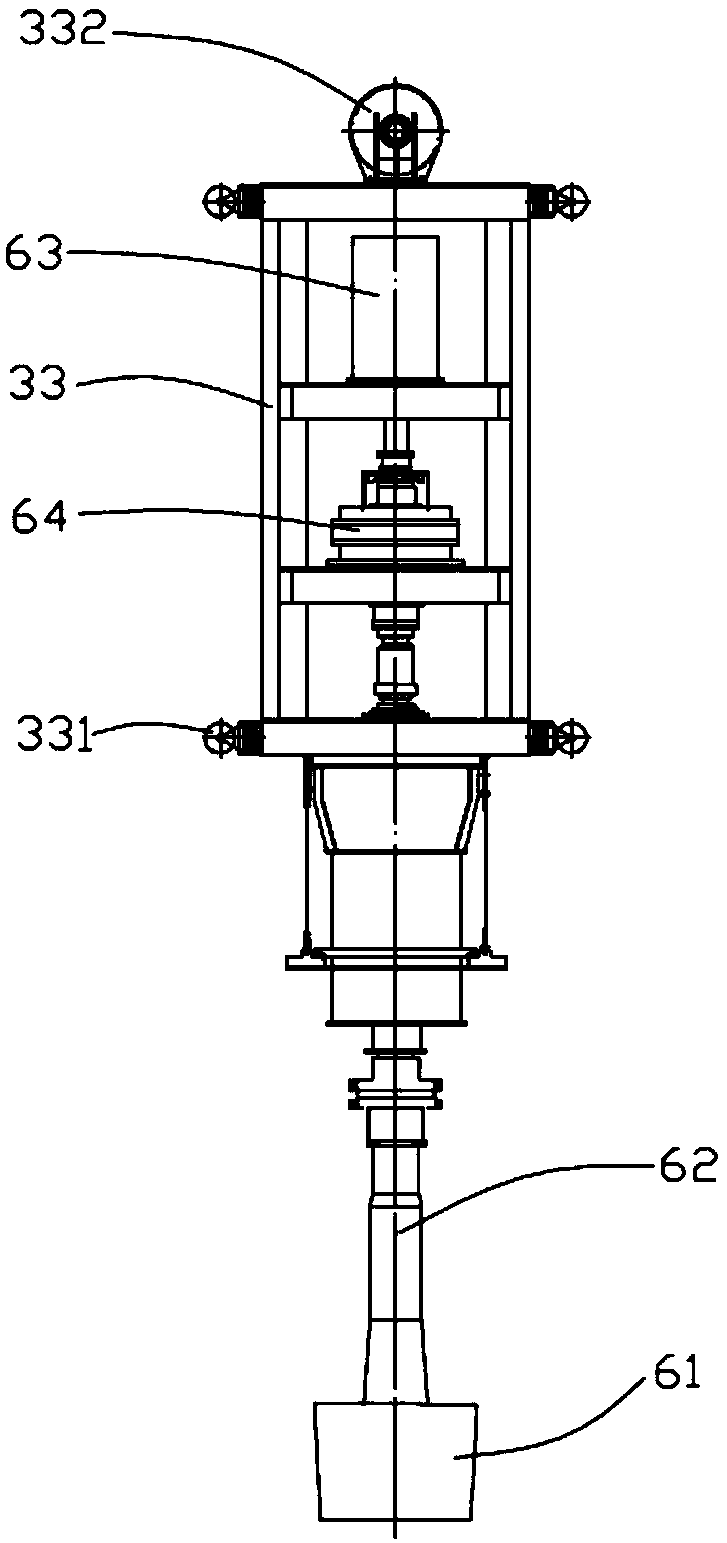

[0028] Such as figure 1 , the embodiment of the present invention provides an agitator traversing trolley 3, including a platform 31 and a traveling mechanism installed at the bottom of the platform 31, the top of the platform 31 is loaded with an agitator 6 and used to drive the A lifting mechanism for lifting and lowering the agitator 6 , the platform 31 is provided with a vertical through hole for the agitator 6 to pass through.

[0029] The agitator traversing trolley 3 provided in this embodiment is used as the carrier of the agitator 6 and the power source to drive the agitator 6 to run between adjacent agitating stations. A set of agitating devices can be applied to multiple desulfurization stations , so that two sets of desulfurization stations can share one stirring device, and the horizontal arrangement only occupies two stations, effectively saving the floor space. Moreover, the molten iron stirring device is separated from the structural platform, avoiding the sha...

Embodiment 2

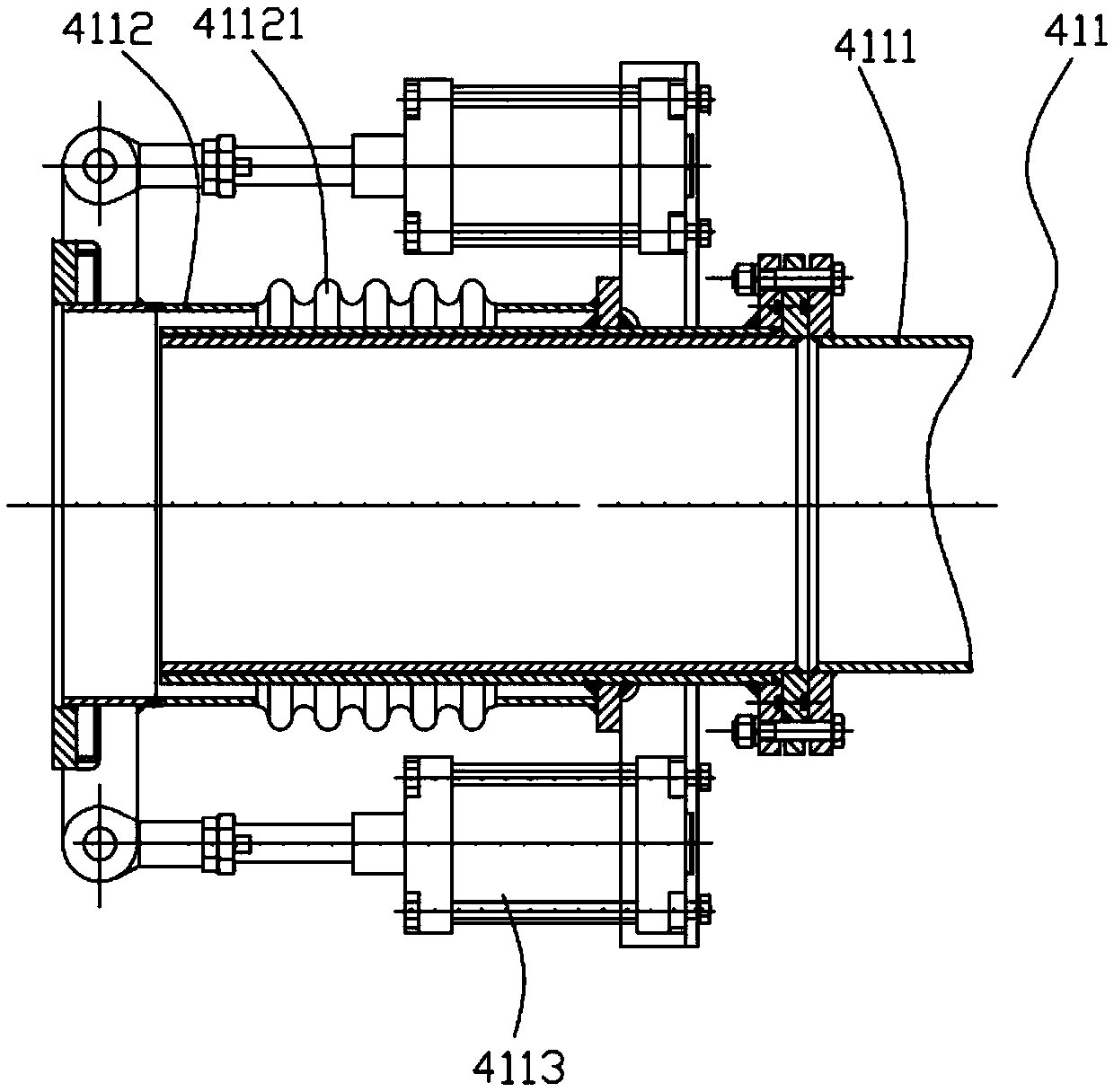

[0038] Such as figure 1 , this embodiment provides a split-type blanking device, including a mobile blanking chute 41 and a plurality of fixed blanking chute 42, the fixed blanking chute 42 is used to be fixedly installed to each corresponding blanking station respectively The mobile blanking chute 41 is connected with a mobile unit that can drive it to move between the blanking stations, so that it can cooperate with the fixed blanking chute 42 of different blanking stations to realize a set of blanking device with multiple services. The blanking work of each station can effectively save the floor space and equipment cost. The above-mentioned moving discharge chute 41 has a docking structure for docking with the fixed discharge chute 42 .

[0039] The docking structure preferably adopts an expansion joint 411, and the structure of the expansion joint 411 has been mentioned in the first embodiment above, and will not be repeated here.

[0040] Further preferably, as figure ...

Embodiment 3

[0044] This embodiment relates to a laterally moving molten iron stirring desulfurization system, including a structural platform 2, two tank transport track lines are arranged in parallel below the structural platform 2, and are used to travel the molten iron tank car 1, and each of the tank transport track lines Correspondingly, there is a stirring station node; two passage holes for the agitator 6 to pass through are provided on the structural platform 2 and a traverse track connecting the two passage holes is arranged in series, and the two passage holes are connected to the two passage holes. Stirring station nodes are facing one by one, and a traversing trolley 3 runs on the traversing track, and the traversing trolley 3 is provided with an agitator 6 and a lifting mechanism for driving the agitator 6 up and down.

[0045] The horizontal moving molten iron stirring desulfurization system provided in this embodiment sets the horizontal moving track and drives the agitator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com