Washing machine

A washing machine and U-shaped technology, applied in the field of washing machines, can solve the problems of complicated design and assembly process, increased height of the washing machine, high manufacturing cost, etc., and achieve the effects of small vibration, reduced vibration and noise, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

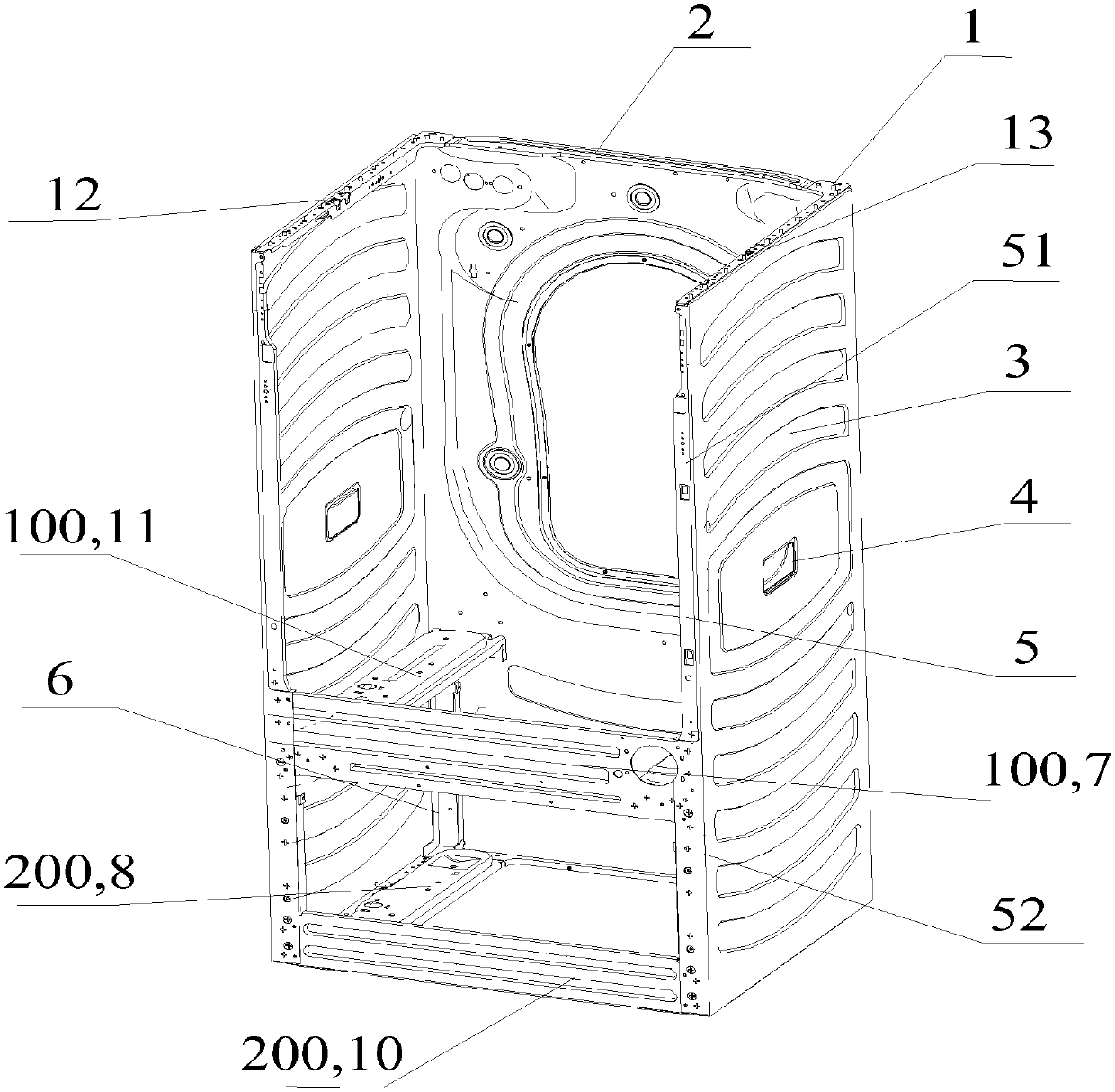

[0057] Such as figure 1 As shown, in this embodiment, the middle reinforcing member arranged in the middle of the U-shaped main body 1 divides the U-shaped main body 1 into two parts, the upper U-shaped main body and the lower U-shaped main body, and the two vertical sides at the front opening of the upper U-shaped main body The edges are respectively bent to form the upper support structure 51 , and the two vertical sides at the opening of the lower U-shaped main body are respectively edge bent to form the lower support structure 52 .

[0058] The design of bending the two vertical sides at the front opening of the U-shaped main body 1 to form the supporting structure 5 enhances the reliability of the U-shaped main body 1, thereby enhancing the reliability of the box body, thereby reducing the work load of the washing machine. Vibration and noise, at the same time, this design is easy to implement.

Embodiment 2

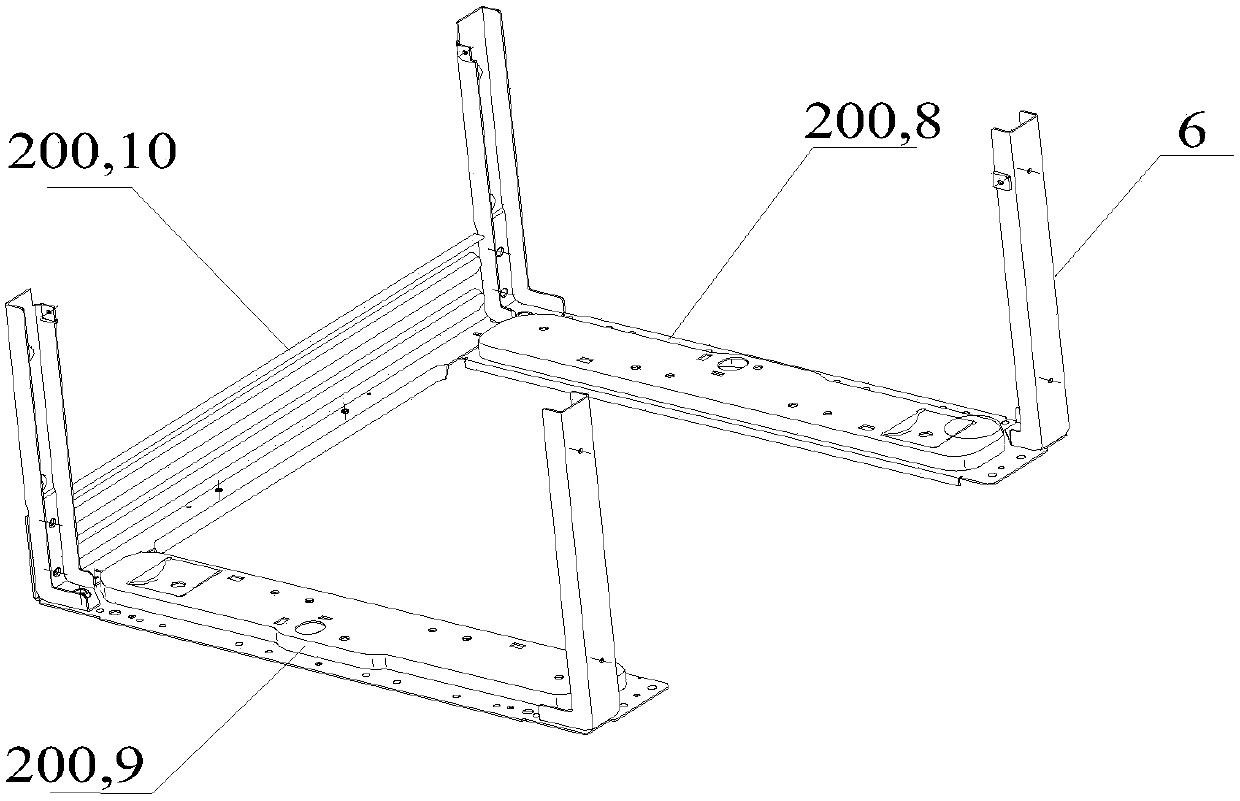

[0060] Such as figure 1 , 3 As shown, the difference between this embodiment and the above-mentioned first embodiment is that the four vertical sides of the U-shaped main body 1 are respectively vertically extending columns 6, and the upper ends of each column 6 are fixedly connected with the middle partition 100, The lower end of each column is fixedly connected with the base 200 of the washing machine, so that the intermediate partition 100, the base 200 of the washing machine and each column 6 constitute the supporting frame of the lower U-shaped main body.

[0061] Preferably, the upper end of each column 6 is fixedly connected to the corresponding left middle reinforcement 11 or the right middle reinforcement 14 respectively, and the lower end of each column 6 is fixedly connected to the corresponding left lower reinforcement 8 or right lower reinforcement 9 respectively.

[0062] The above arrangement further enhances the reliability of the U-shaped main body 1, thereby...

Embodiment 3

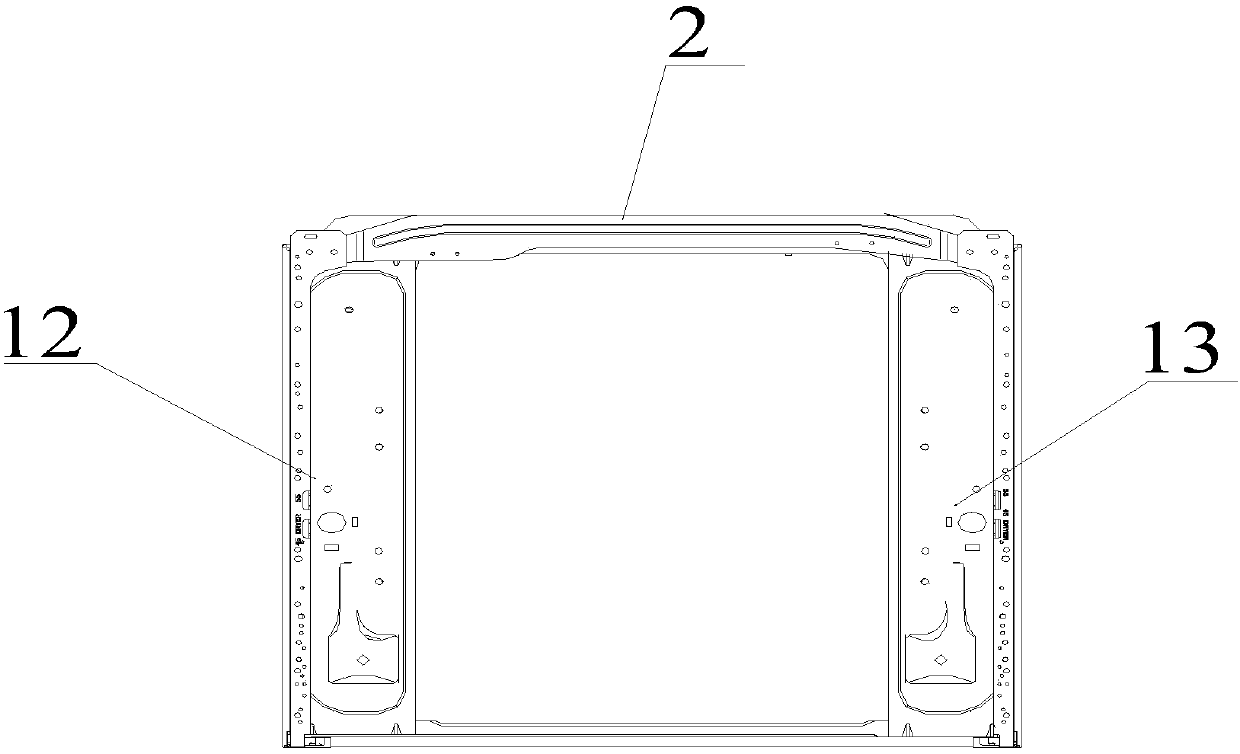

[0072] Such as figure 1 , 3 As shown, the difference between this embodiment and the above-mentioned embodiments 1 to 2 is that the upper end of each column 6 is fixedly connected to the corresponding upper left reinforcing member 12 or upper right reinforcing member 13, and the lower end of each column is fixedly connected to the base 200 of the washing machine. , so that the upper left reinforcement 12 , the upper right reinforcement 13 , the base 200 of the washing machine and the columns 6 constitute the supporting frame of the U-shaped main body 1 .

[0073] Preferably, the lower end of each column 6 is fixedly connected to the corresponding lower left reinforcing piece 8 or lower right reinforcing piece 9 respectively.

[0074] More preferably, the middle part of each column 6 is connected with the middle partition 100 .

[0075] Further preferably, the middle part of each column 6 is fixedly connected with the corresponding left central reinforcement 11 or right centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com