Hydraulic engineering device

A technology for water conservancy and start-up devices, which is applied in construction, sheet pile walls, infrastructure engineering and other directions, can solve the problems of inability to hammer, high noise, disturbing people, etc., and achieves the effect of preventing the center of gravity from being unstable and improving the stability of operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

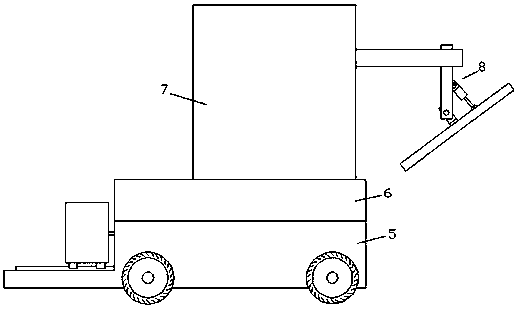

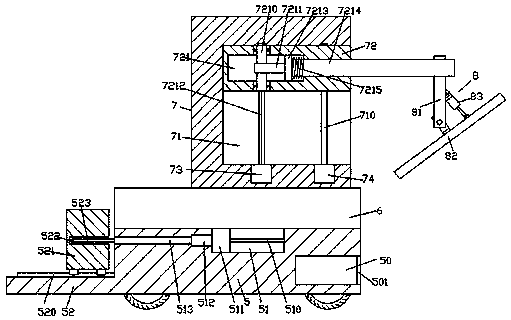

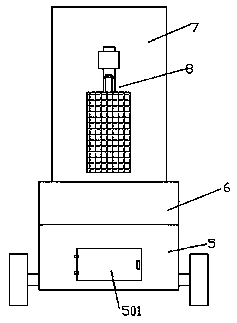

[0015] Such as figure 1 , figure 2 and image 3 As shown, a water conservancy device of the present invention includes a base 5, a sliding frame 6 mounted on the top of the base 5 with smooth fit, and a height adjustment machine 7 fixed on the top of the sliding frame 6, and the top of the base 5 is A first guide chute 51 is provided in the plane, and a first screw rod 510 extending left and right is arranged in the first guide chute 51, and the left extension end of the first screw rod 510 is connected with the first power machine 512 Fitting connection, the outer surface of the first power machine 512 is set in the left inner wall of the first guide chute 51, and the right side extension tip of the first screw rod 510 is connected with the right inner wall of the first guide chute 51. Revolving fit connection, the first guide slider 511 is connected with the first screw rod 510 in a smooth fit in the first guide groove 51, and the top end of the first guide slider 511 is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap