Manufacturing method of titanium golf head by different-weight forging

A technology of golf head and manufacturing method, which is applied in the direction of manufacturing tools, forging/pressing/hammering machinery, forging/pressing/hammering devices, etc., which can solve problems such as low precision, high technical requirements for workers, and unstable center of gravity. Achieve the effect of meeting the requirements of manufacturing and use, solving the problem of low precision and long processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

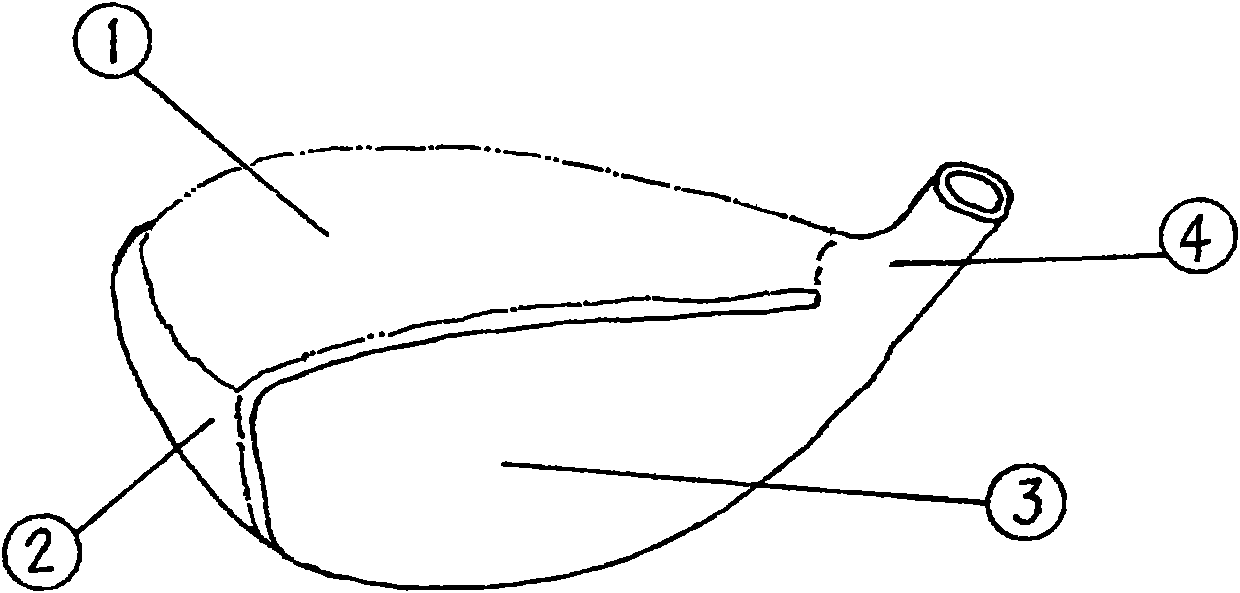

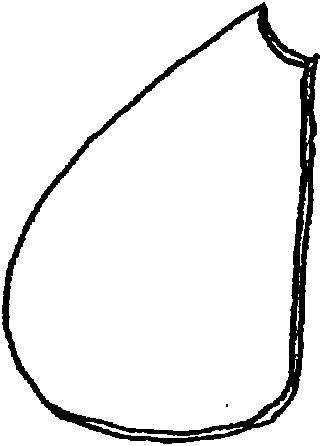

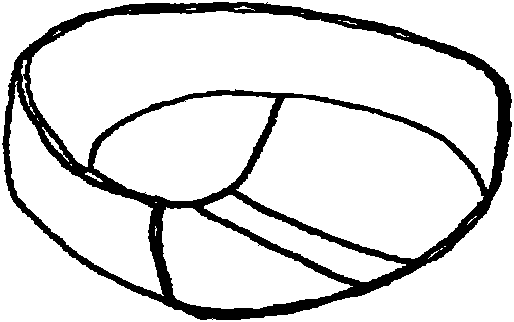

[0017] figure 1 It is a schematic diagram of the overall structure of a golf head, figure 2 , image 3 , Figure 4 It is a structural schematic diagram of the three pieces of blanks that constitute the upper cover 1, the lower bottom 1, and the striking surface 3 with the tube head 4. Specifically, the golf head and the The shape of the billet. Die forging is to accurately control the weight and center of gravity of each piece of blank by computer according to the material density of the blank, and precisely forge three pieces of blanks, so that any combination of the same batch of materials can find the accurate center of gravity. During welding, the argon arc welding machine is automatically controlled to realize the automatic welding and forming of three blanks, and complete the production of golf balls.

[0018] In steps b and c of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com