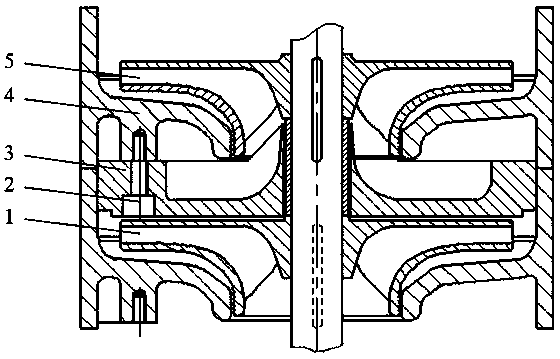

Compact liquefied natural gas immersed pump guide vane structure

A technology for liquefied natural gas and submersible pumps, which is applied to pumps, pump components, non-variable-capacity pumps, etc., can solve problems such as unfavorable rear-stage impeller performance, increase the overall manufacturing cost, reduce the efficiency of the whole pump, etc., and achieve a compact structure design. , reduce hydraulic loss, reduce the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

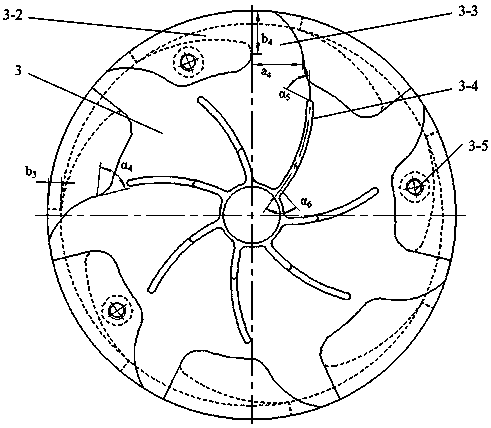

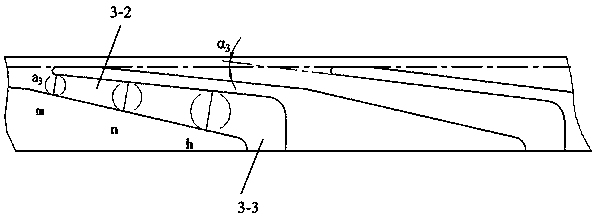

[0022] Embodiment one: if figure 2 As shown, the guide vane flow channel 3-2 is arc-shaped, and is evenly distributed on the same circumference of the outer edge of the guide vane body 3-1. u R=K (velocity moment remains constant) regular flow characteristics, designed guide vane flow channel inlet placement angle α 3, Make the liquid enter the flow channel smoothly and reduce the impact. The liquid enters the guide vane back blade flow channel through the guide vane flow channel liquid outlet 3-3, the position of the guide vane flow channel liquid outlet 3-3 is similar to the guide vane back blade 3-4, and the liquid outlet angle is α 4 Placement angle α with guide vane back blade inlet 5 They are all designed according to the law that the velocity moment remains constant, so that the liquid can flow into the flow channel of the guide vane back blade better, reducing the impact loss and energy loss. Such as image 3 As shown, the guide vane flow channel 3-2 has a gradual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com