Mechanical part connecting piece capable of being independent of elastic washer

A technology of mechanical parts and elastic washers, which is applied in the direction of connecting components, mechanical equipment, threaded fasteners, etc., to achieve the effect of easy tightening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

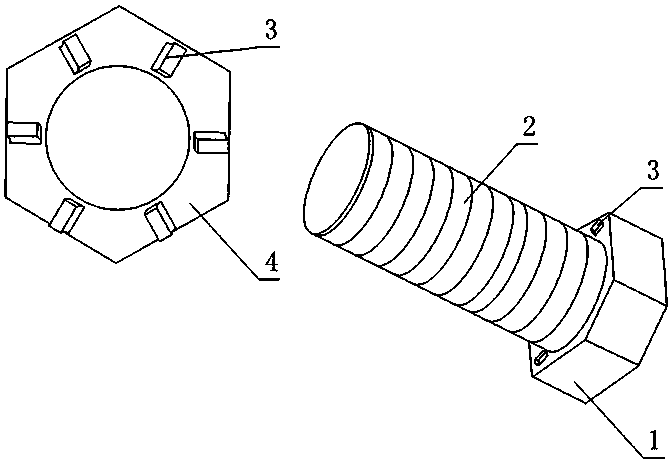

[0021] Such as figure 1 As shown, a mechanical part connector that does not rely on elastic washers includes a screw and a nut, the nut includes a nut body 4, and the bolt includes a screw section and a nut end 1 arranged at the end of the screw section , the end surface of the nut end 1 close to the screw section and the end surface of the nut body 4 close to the nut end 1 are provided with a plurality of elastic protrusions 3, and the elastic protrusions 3 can be formed during the tightening of the bolt Elastic deformation; the free end of the elastic protrusion 3 is set to be inclined toward the direction of loosening the connecting parts of the mechanical parts.

[0022] In this structure, the set screw section 2 has threads, which are used for threaded connection with the nut in the bolt connection to fasten the interconnected connectors. The above nut end 1 is used as the driving force for the operator to brake the rotation of the screw section 2. part. In this structu...

Embodiment 2

[0026] Such as figure 1 As shown, this embodiment is further limited on the basis of Embodiment 1: in order to make the above prestress evenly distributed in the circumferential direction of the bolt, the elastic protrusions 3 on both end surfaces are annular with respect to the axis of the screw segment 2 Evenly distributed.

[0027] As a further technical solution to make the above prestress evenly distributed in the circumferential direction of the bolt, the number of elastic protrusions 3 on both end faces is greater than three.

[0028] As a connector form that is convenient for processing and manufacturing, the elastic protrusion 3 on the nut end 1, the screw section and the nut end 1 is an integral structure formed by casting; the nut body 4 and the nut body The elastic protrusion 3 on the 4 is an integral structure formed by casting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com