A single-spring piston type pneumatic two-position shut-off valve

A piston-type, single-spring technology, which is used in lift valves, valve details, valve devices, etc., can solve the problems of increased leakage frequency at the stuffing box, complex connection structure between bracket and valve body, and low assembly and disassembly work efficiency. Achieve the effect of lowering temperature, reducing space and labor intensity, and reducing leakage frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

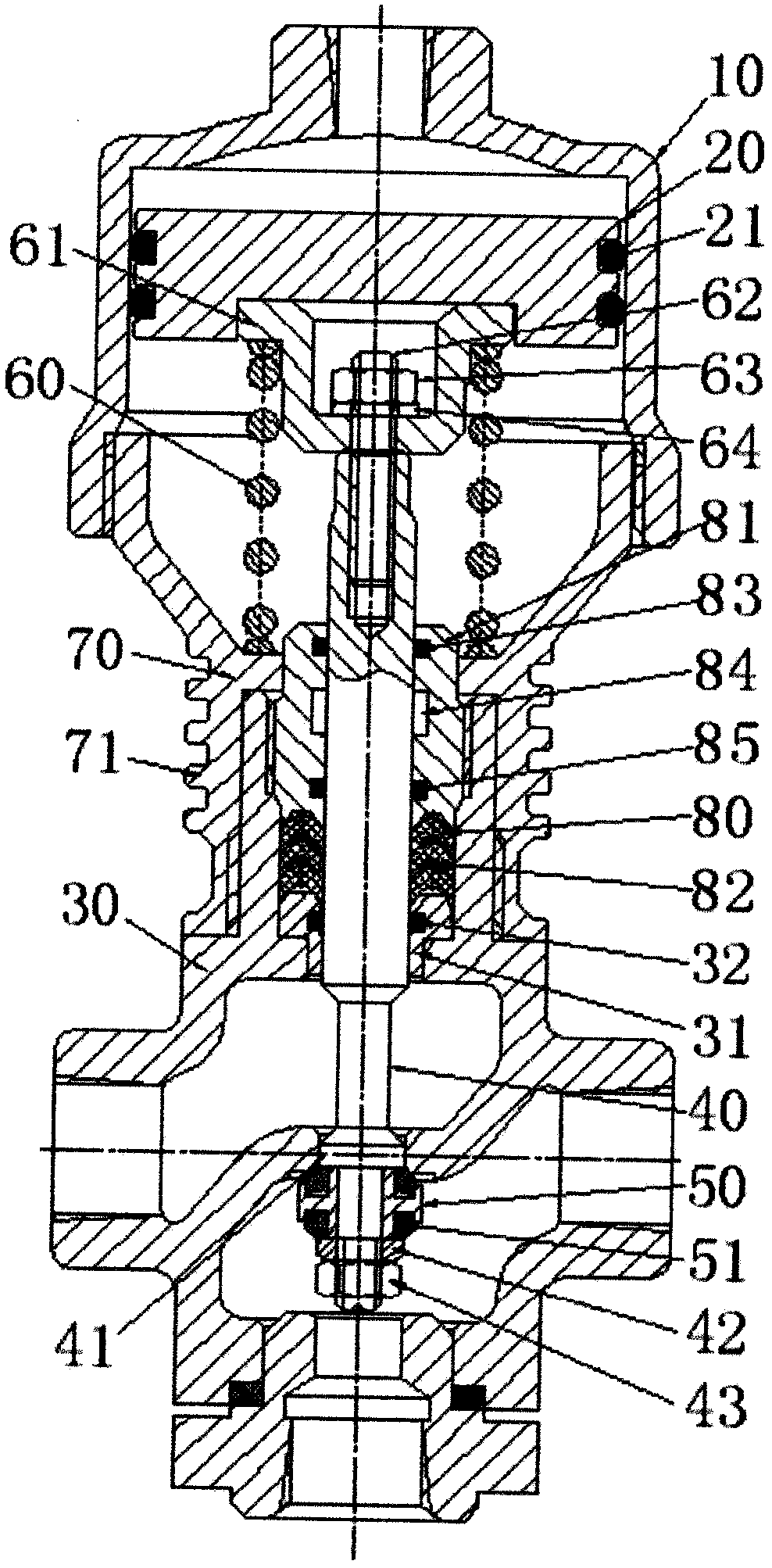

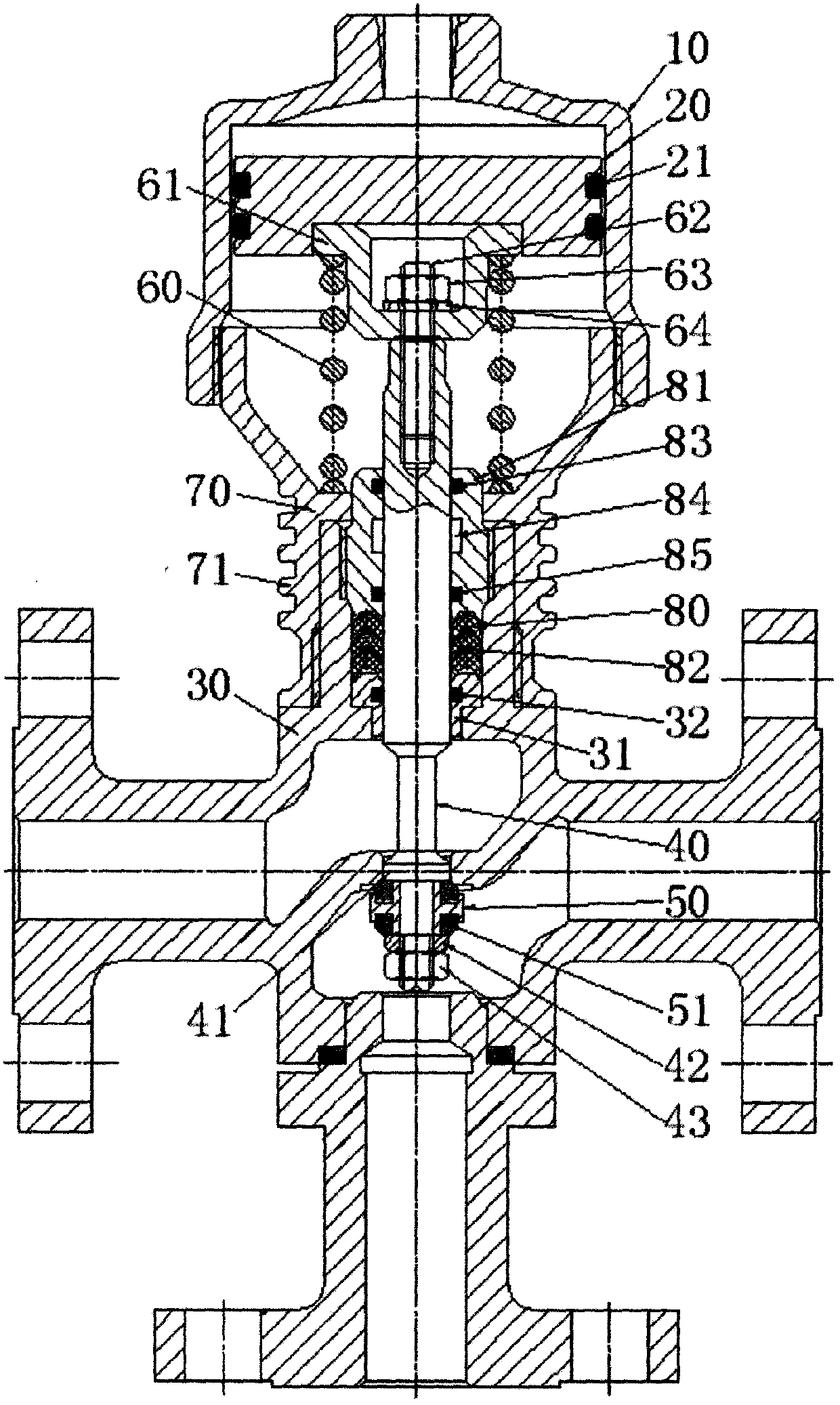

[0019] refer to Figure 1 to Figure 2 , Figure 1 to Figure 2 It is a structural schematic diagram of a specific embodiment of the present invention.

[0020] like figure 1 and figure 2 As shown, a single-spring piston type pneumatic two-position cut-off valve includes a cylinder 10, a piston 20, a valve body 30, a valve stem 40, a valve core 50 and a spring 60, the piston 20 is arranged in the cylinder 10, and the The valve core 50 is arranged in the valve body 30, and the piston 20 and the valve core 50 are respectively fixedly arranged on both ends of the valve stem 40, and the spring 60 is sleeved on the valve stem 40; The spring 60 is disposed between the piston 20 and the valve body 30 . It also includes a bracket 70 arranged between the cylinder 10 and the valve body 30, the upper end of the bracket 70 is connected with the cylinder 10 through threads, and the lower end of the bracket 70 is connected with the valve body 30 through threads , the bracket 70 is sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com