Air pressure testing system

A technology of air pressure test and barometer, which is applied in the direction of measuring devices, measuring fluid pressure, instruments, etc., can solve the problems of time-consuming, inconvenient, and unfavorable batch testing and production of disassembling and assembling sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In the following, the present invention will be further described in conjunction with the drawings and specific implementations. It should be noted that, provided that there is no conflict, the following embodiments or technical features can be combined to form new embodiments. .

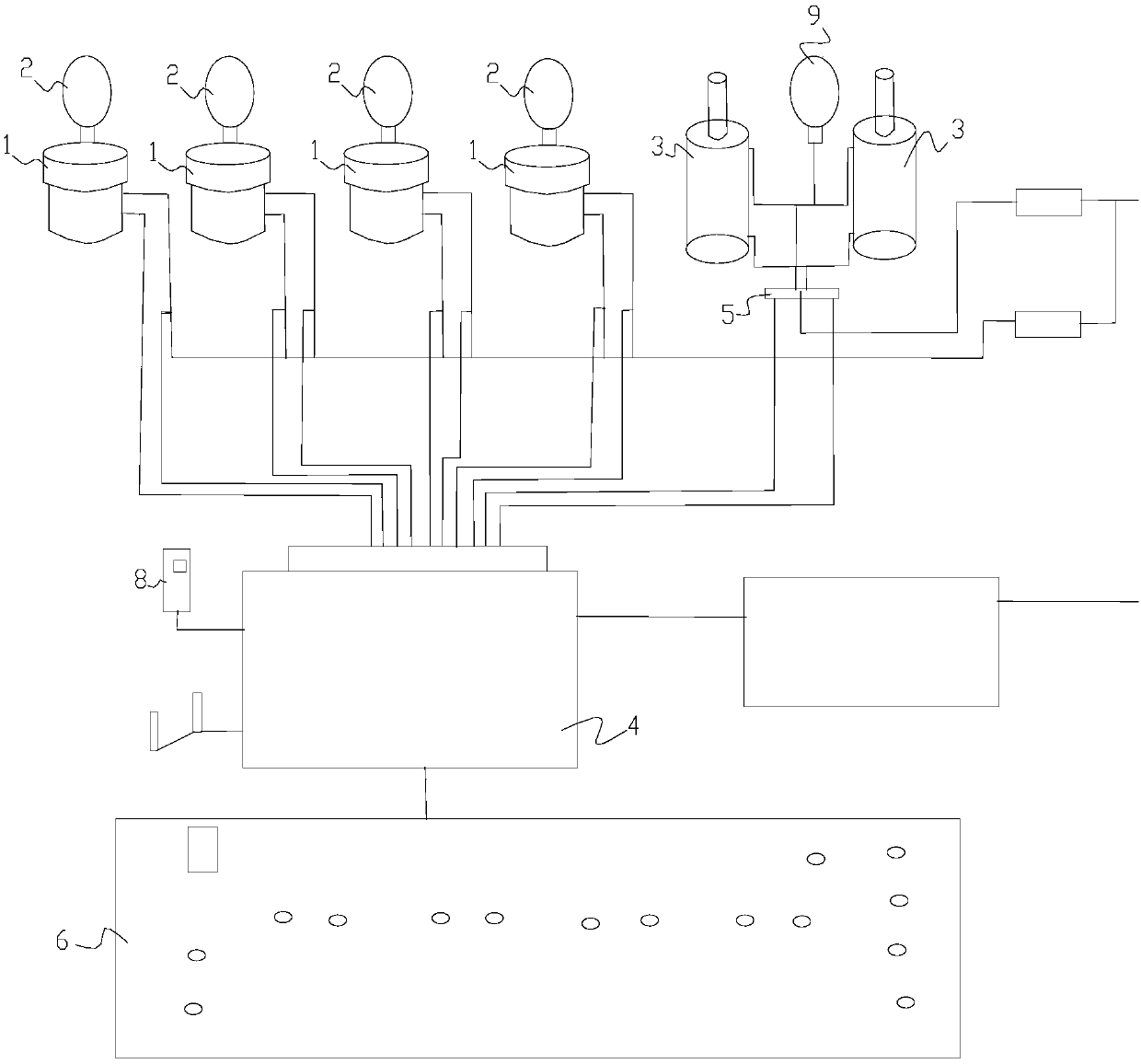

[0023] See figure 1 , The present invention relates to an air pressure test system, which includes a sealed test container 1, a first air pressure gauge 2, a tire pressure sensor, a cylinder 3, a controller 4, a solenoid valve 5, an operation panel 6, a bracket, a pressure sensor 8, and a driving device , Pressure rod, second barometer 9 and receiver.

[0024] The sealed test container 1, the cylinder 3 and the controller 4 are mounted on the bracket. The sealed test container 1 includes an upper shell, a sealing ring and a lower shell. The upper shell and the lower shell are mutually covered to form a sealed test container 1. The sealing ring is installed between the upper shell and the lower s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com