Adjustable test bed of nails for circuit board

A test bed of needles and adjustable technology, applied in the field of test needle beds, can solve the problems of fixed device structure, poor applicability, inability to adjust conveniently, etc., achieve simple device structure, flexible and convenient adjustment operation, improve control efficiency and The effect of processing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

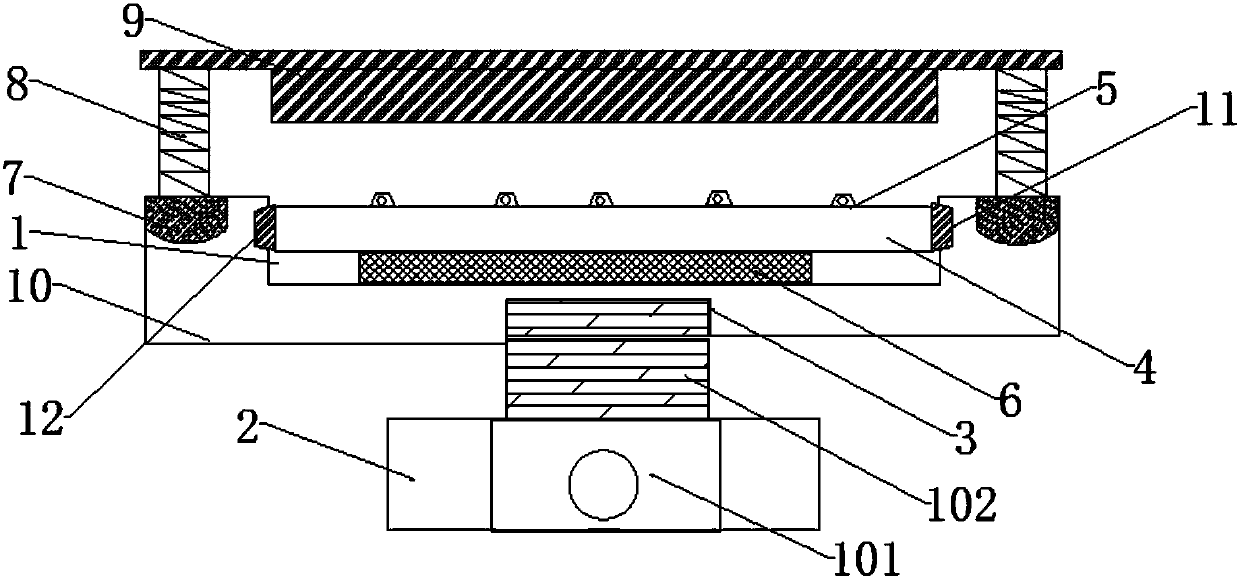

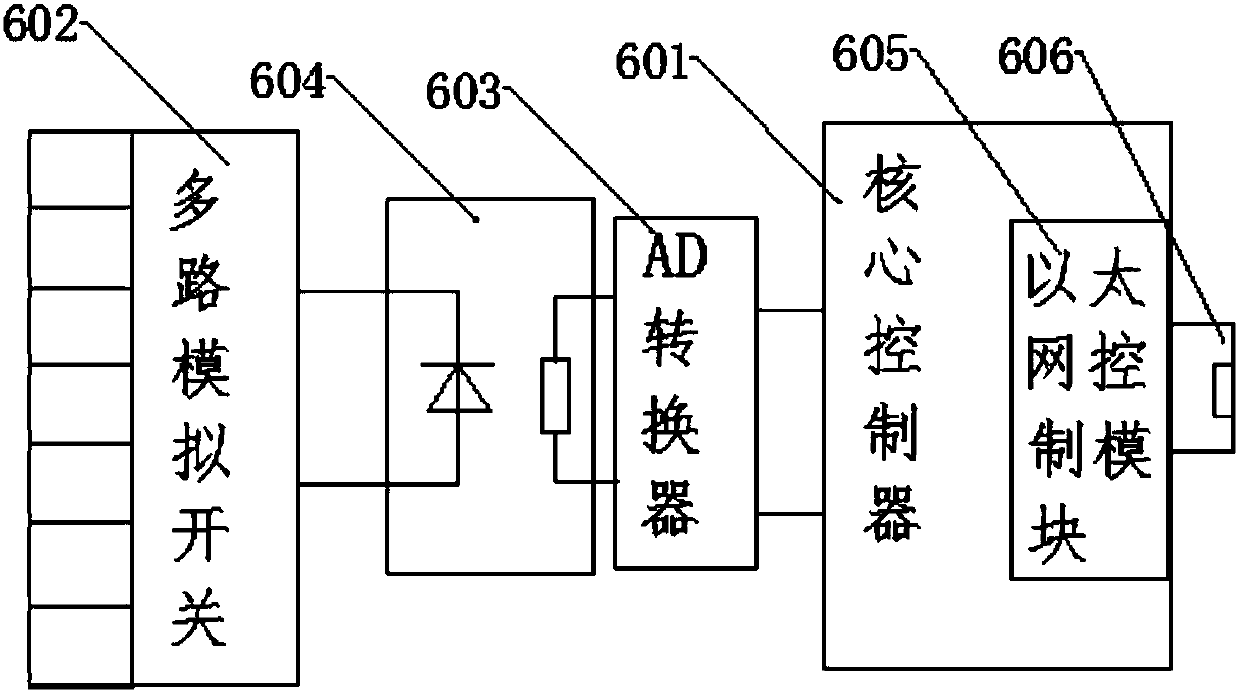

[0023] Such as figure 1 As shown, the present invention provides an adjustable test bed of needles for circuit boards, including an adjustable support base 1, the top of the adjustable support base 1 is fixed with a fixed base plate 2, and the center of the fixed base plate 2 is A circular threaded fixing hole 3 is excavated on the surface. The adjustable support base 1 includes a lifting motor 101. The output shaft of the lifting motor 101 is sleeved with a lifting sleeve shaft 102. The top of the lifting sleeve shaft 102 is engraved with The external thread is matched with the threaded fixing hole 3; the lifting motor 101 is used to control the up and down operation. The adjustment operation of the height of the top fixed bottom plate 2 can also be easily disassembled;

[0024] The center of the upper surface of the fixed base plate 2 is dug with a fixed groove 10, and the inside of the fixed groove 10 is inlaid with a test base plate 4, and the inner wall of the fixed groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com