Maintenance risk based power equipment operation schedule optimizing method

A power equipment, operation and maintenance technology, applied in the field of power equipment operation and maintenance plan optimization based on maintenance risk, can solve the problems of difficult model extraction, difficult to implement algorithms, and large amount of calculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following descriptions of various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present invention can be implemented.

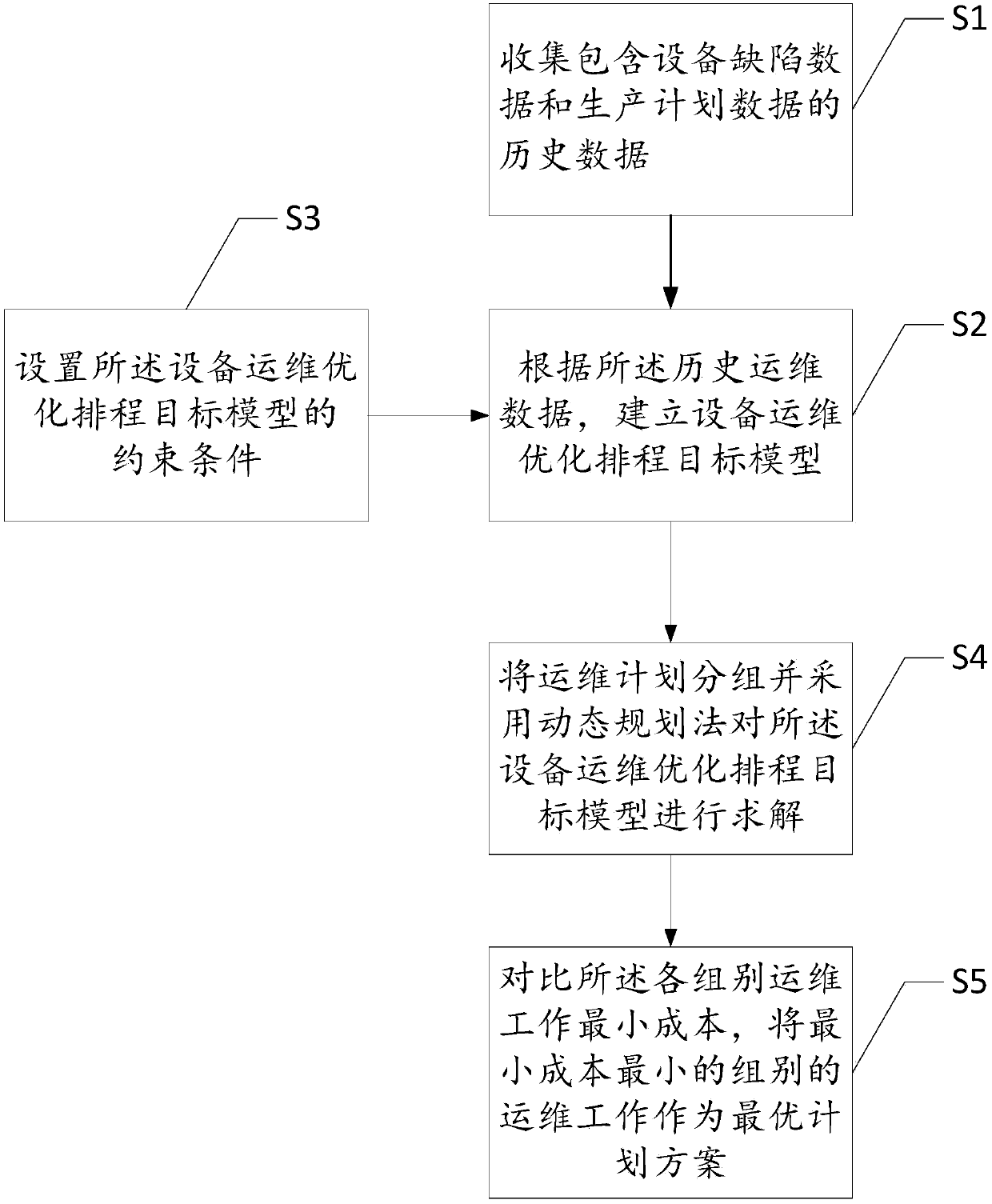

[0024] figure 1 A schematic flowchart of a method for optimizing operation and maintenance planning of electric equipment based on maintenance risks is provided for an embodiment of the present invention. As an example, the optimization and scheduling process of the operation and maintenance plan for the following generating units is as follows.

[0025] Step S1, collecting historical operation and maintenance data including equipment defect data and production planning data. The defect data includes: the number of defects found in the inspection work and the time for eliminating defects, the number of defects found in the test work and the time for eliminating defects, the number of defects found in the maintenance work and the time for eliminating defects, the number of defects found in the mainte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com