Plastic stool

A plastic stool and plastic technology, applied in the direction of stools, chairs, household appliances, etc., can solve the problems of increasing the weight of plastic stools, poor comfort, increasing costs, etc., achieving a simple and reasonable structure, improving product quality and service life, and enhancing stability. sexual effect

Pending Publication Date: 2018-03-09

杨兆金

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, the plastic stools on the market are basically made of polypropylene at one time. They have the advantages of being foldable, light, and easy to store and are widely used. Especially workers in factories sometimes need to sit on plastic stools all day at work. Because plastic stools There are reinforcing ribs on the seat surface of the plastic stool, which will make you feel uncomfortable after sitting for a long time, and the comfort level is poor. At present, there is also a design of adding a layer of soft cushion on the top of the plastic stool seat surface, but this not only increases the cost, but also increases the cost of the plastic stool. weight, making it inconvenient to use

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

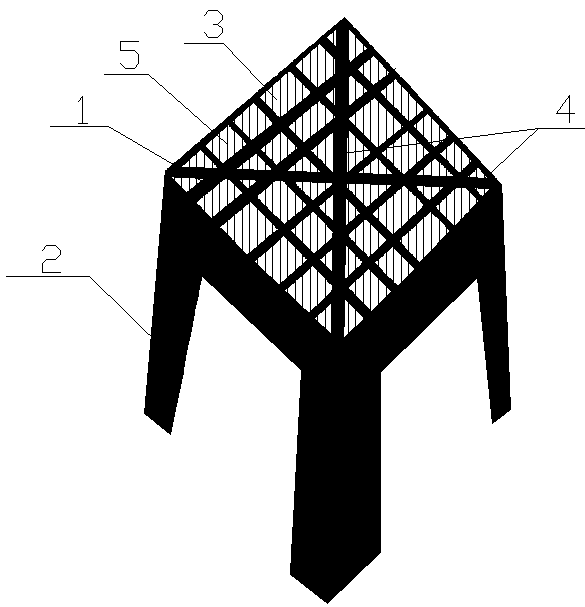

[0009] Such as figure 1 As shown, the present invention comprises seat surface 1, stool leg 2, and described seat surface 1 and stool leg 2 are integral injection molding of plastic; It is divided into grids; two crossing ribs 4 are arranged on the two diagonals of the seat surface 1; a thermoplastic elastomer 5 is arranged in the through hole 3 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A plastic stool relates to the technical field of design of plastic stools. The plastic stool includes a seat surface and stool legs which are shaped in a plastic integrated injection moulding manner.A plurality of holes are uniformly formed in the seat surface. Thermoplastic elastomer is formed in the holes. The seat surface and stool legs are shaped from polypropylene in a one-step injection moulding manner, wherein the holes are reserved in the seat surface, then the thermoplastic elastomer (such as TPR and TPE, etc.) is injected into the holes, so that the seat surface has excellent elasticity. The plastic stool has simple and reasonable structure and is comfortable and soft.

Description

technical field [0001] The invention relates to the technical field of design of plastic stools. Background technique [0002] At present, the plastic stools on the market are basically made of polypropylene at one time. They have the advantages of being foldable, light, and easy to store and are widely used. Especially workers in factories sometimes need to sit on plastic stools all day at work. Because plastic stools There are reinforcing ribs on the seat surface of the plastic stool, which will make you feel uncomfortable after sitting for a long time, and the comfort level is poor. At present, there is also a design of adding a layer of soft cushion on the top of the plastic stool seat surface, but this not only increases the cost, but also increases the cost of the plastic stool. The weight makes it inconvenient to use. Contents of the invention [0003] The object of the present invention is to provide a comfortable plastic stool for the above problems. [0004] Th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A47C5/12A47C7/16

CPCA47C5/12A47C7/025A47C7/16

Inventor 杨兆金

Owner 杨兆金

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com