Crushing component of vertical type garbage crusher

A crusher and garbage technology, applied in grain processing, etc., can solve the problems of low work efficiency, high manufacturing cost, and low work efficiency, and achieve the effects of improving crushing capacity and efficiency, strong market competitiveness, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

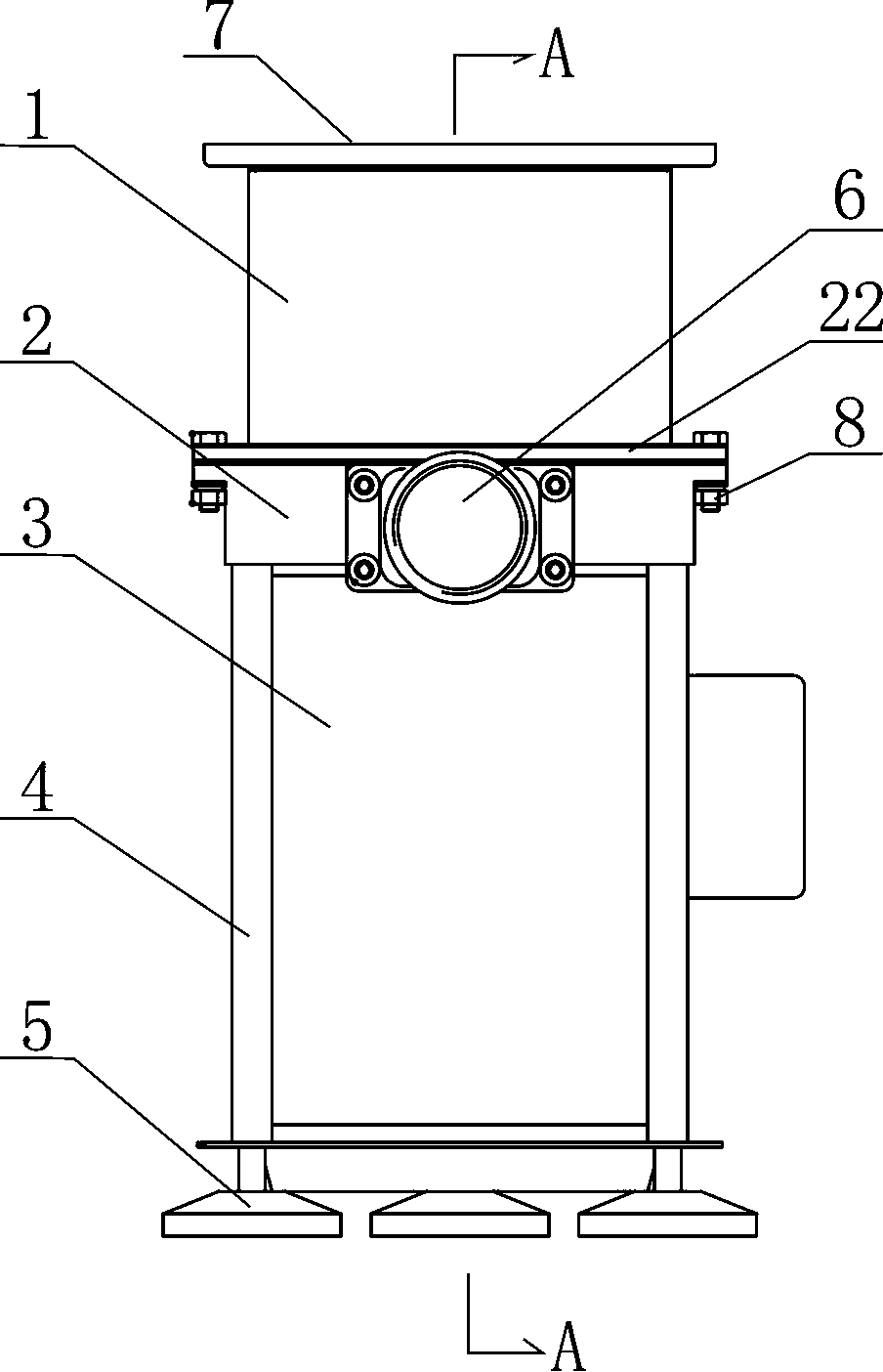

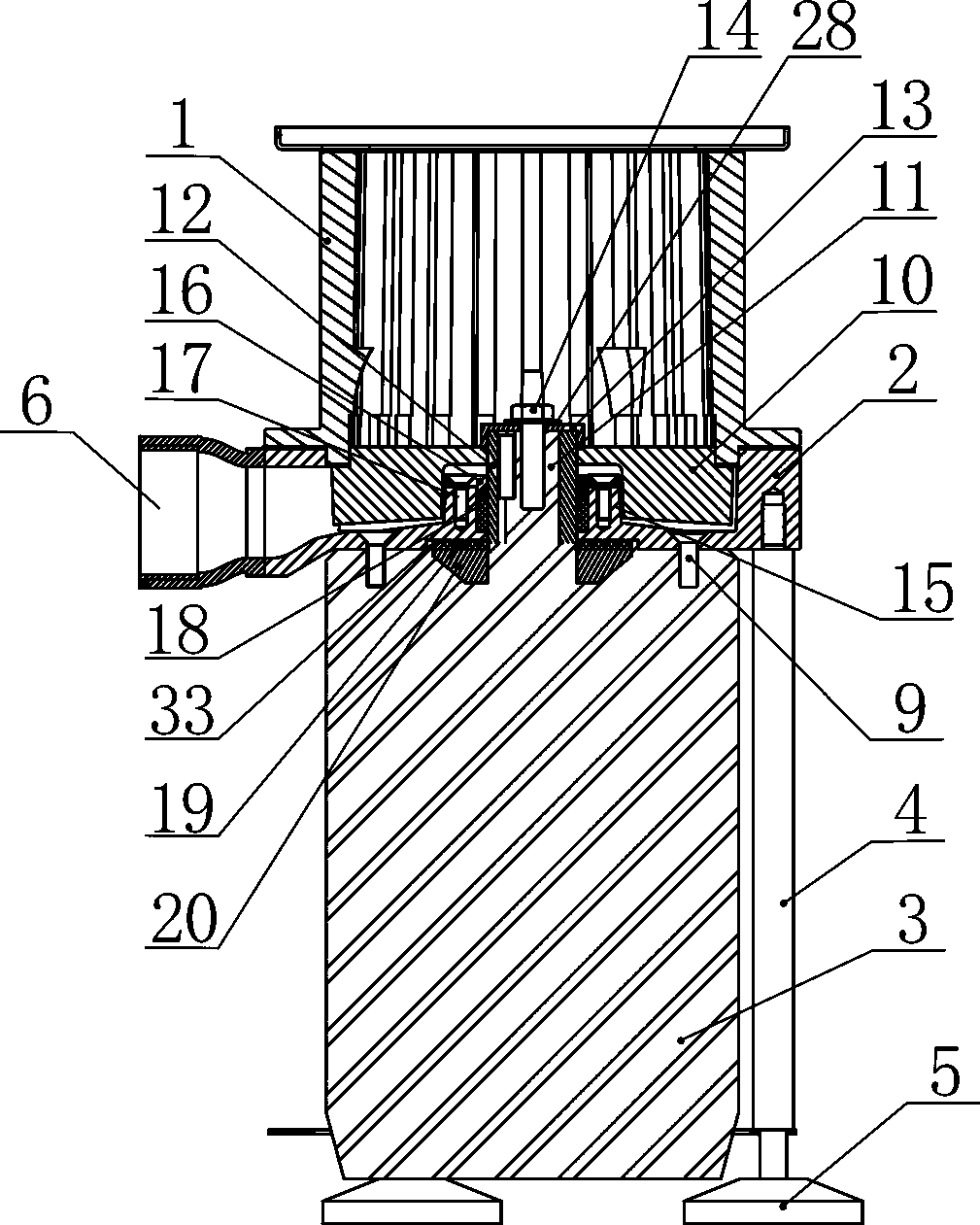

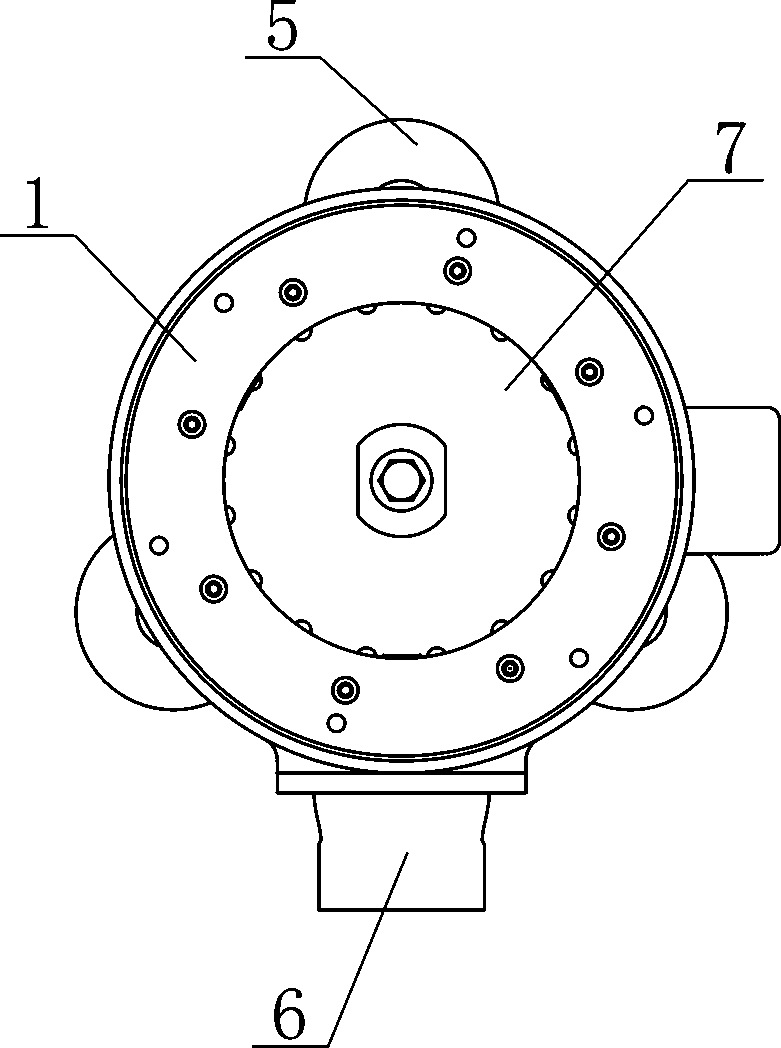

[0026] like figure 1 , 2 , 3, 4, 5, 6, 7, and 8, the vertical garbage crusher includes a crushing cylinder 1, a slag discharge chamber 2, a crushing disc 10 and a motor 3, and the slag discharge chamber 2 is supported on the support rod 4 At the top, the bottom of the support rod 4 is provided with height adjustment feet 5, and the support rod 4 is provided with at least three. The outlet port of the crushing cylinder is the garbage inlet 7, and the lower port of the crushing cylinder 1 is connected to the top of the slag discharge chamber 2. The specific connection method is: the lower port of the crushing cylinder 1 is provided with a flange 22, and the flange 22 passes through the bolt 8 Connected with the top of the slag chamber 2, the side wall of the slag chamber 2 is provided with a garbage outlet 6, the motor 3 is arranged at the bottom of the slag chamber 2, and the bottom surface of the slag chamber 2 is located at the center hole 29 A plurality of installation hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com